Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

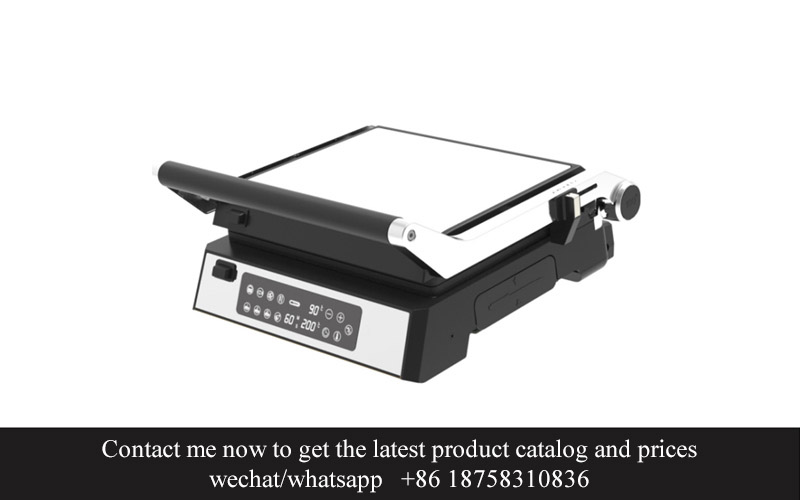

The evolution of kitchen appliances has transformed the way we approach cooking, and among these innovations, the sandwich press stands out as a testament to culinary convenience. With its ability to effortlessly toast the perfect sandwich, this humble kitchen gadget has found its way into households around the world. This article delves into the fascinating world of sandwich presses, exploring their design, functionality, and the impact they have on the way we savor our meals.

The dual voltage sandwich press market has been experiencing a surge in demand, especially with the increasing popularity of gourmet and fast-casual dining trends. This segment of the kitchen appliance industry is characterized by its unique ability to cater to diverse electrical standards across the globe. In this brief overview, we delve into the key aspects that define the dual voltage sandwich press market.

Sandwich presses are not just a convenience for the home chef; they have become a staple in restaurants, cafes, and food trucks. The versatility of these appliances lies in their ability to provide consistent and high-quality results, regardless of whether they are used in countries with 120V or 240V electrical systems. This dual voltage capability is a significant factor that has contributed to the growth of this market.

In regions like North America, where 120V is the standard, dual voltage sandwich presses are a game-changer for operators looking to maintain consistency in their sandwich offerings. They ensure that the same great taste and texture can be achieved across different locations, even if the voltage varies.

On the other hand, countries with 240V systems, such as much of Europe and Asia, benefit from the convenience of a single appliance that can be used without the need for voltage conversion. This not only simplifies the operation but also reduces the risk of electrical issues that can arise from improper voltage adaptation.

The market for dual voltage sandwich presses is not limited to commercial use; it’s also gaining traction in the home appliance sector. Home cooks who are passionate about their culinary creations are increasingly turning to these versatile appliances to experiment with different sandwich recipes.

One of the key drivers of the dual voltage sandwich press market is the emphasis on convenience and speed. In today’s fast-paced world, the ability to quickly prepare a delicious sandwich is highly valued. These presses are designed to deliver perfect grilling marks and caramelization on the bread, which adds to the appeal of the final product.

The demand for these presses is also influenced by the rise of health-conscious consumers. As more people look for nutritious yet satisfying meals, the sandwich, with its customizable ingredients, has become a go-to option. Dual voltage sandwich presses allow for the perfect combination of toasted bread, melted cheese, and other fillings, making them a favorite among health enthusiasts.

From a product development perspective, manufacturers are focusing on innovation to meet the evolving needs of consumers. Features such as non-stick surfaces, adjustable heat settings, and compact designs are becoming standard in new models. These advancements not only enhance the user experience but also contribute to the market’s growth.

When it comes to distribution, the dual voltage sandwich press market is seeing a shift towards online sales. E-commerce platforms are making it easier for consumers to purchase these appliances from anywhere in the world, which has expanded the market’s reach. Additionally, the rise of cross-border e-commerce has opened up new opportunities for international brands to enter new markets.

The competitive landscape of the dual voltage sandwich press market is diverse, with several established players and emerging brands vying for market share. These companies are constantly striving to differentiate themselves through product features, design, and customer service. Collaborations with local distributors and retailers are also a common strategy to gain a competitive edge.

From an environmental standpoint, the dual voltage sandwich press market is also responding to the growing demand for sustainable and energy-efficient appliances. Manufacturers are exploring materials and designs that reduce the carbon footprint and energy consumption of these presses.

In conclusion, the dual voltage sandwich press market is a dynamic and growing sector within the kitchen appliance industry. Its ability to cater to a wide range of electrical standards, combined with the increasing popularity of sandwiches as a meal option, has positioned it for continued expansion. As consumer preferences evolve and new technologies emerge, the dual voltage sandwich press market is poised to play a pivotal role in shaping the future of kitchen appliances.

The dual voltage capability in sandwich presses is not just a feature; it’s a cornerstone of modern culinary technology. In a market that spans across the globe, the ability to operate at two different voltage standards—120V and 240V—is crucial for several reasons.

In the first place, the global reach of the sandwich press market is expansive. From the bustling streets of Tokyo to the cafes of Paris, from the diners of New York to the bakers of Sydney, the demand for high-quality sandwich presses is universal. This vast geographic distribution necessitates a product that can cater to diverse electrical systems without compromising on performance or safety.

Furthermore, the dual voltage design offers a level of convenience that is hard to match. For businesses that operate in multiple regions or those looking to expand their market overseas, having a sandwich press that can adapt to local voltage requirements is invaluable. This flexibility eliminates the need for expensive transformers or voltage conversion kits, streamlining the operation and potentially reducing maintenance costs.

The safety aspect cannot be overstated. Voltage fluctuations can be a common issue, especially in areas prone to power outages or frequent electrical system changes. A sandwich press that can handle both 120V and 240V voltages is inherently more resilient to these challenges, ensuring consistent operation and preventing potential hazards that could arise from voltage mismatches.

Moreover, the dual voltage capability of sandwich presses aligns with the industry’s trend towards innovation. As consumers seek out products that are versatile and can cater to various needs, the dual voltage feature becomes a testament to the press’s adaptability. It’s not just a tool for making sandwiches; it’s a versatile appliance that can serve multiple purposes in different settings.

From a commercial perspective, the dual voltage sandwich press opens up new markets for manufacturers and distributors. In regions where the standard voltage differs from that in North America and Europe, the dual voltage feature can be a significant selling point. This allows businesses to cater to a broader audience and increase their market share.

Additionally, the dual voltage sandwich press can significantly enhance user experience. Whether it’s a home chef looking to replicate the flavors of a café or a café owner looking to expand their menu offerings, the versatility of a dual voltage press means they can do so without worrying about compatibility issues.

The environmental impact of electronic devices is also a growing concern. By designing appliances that can handle both voltage standards, manufacturers contribute to a more sustainable future. These products can be used across different regions, reducing the need for production and disposal of multiple versions of the same appliance.

In terms of technical innovation, the inclusion of dual voltage capability in sandwich presses requires careful engineering. It involves designing circuits and components that can safely switch between voltages without compromising the appliance’s performance. This engineering feat showcases the manufacturer’s commitment to quality and customer satisfaction.

Lastly, the dual voltage sandwich press reflects the evolving landscape of the kitchen appliance industry. As technology advances and consumer expectations rise, the ability to provide a product that is both powerful and adaptable is key. It’s not just about making a sandwich; it’s about providing a solution that fits seamlessly into a wide range of environments and needs.

In summary, the importance of 120V/240V dual voltage in the sandwich press industry cannot be underestimated. It’s a feature that enhances safety, convenience, and user experience, while also opening up new markets and aligning with the industry’s commitment to innovation and sustainability.

In the ever-evolving landscape of the kitchen appliances industry, OEM (Original Equipment Manufacturer) solutions have become a cornerstone for brands looking to expand their market reach and offer consumers products that resonate with their needs and preferences. When it comes to the sandwich press market, innovation isn’t just about creating a new product; it’s about understanding the global consumer and providing solutions that cater to diverse electrical standards and culinary expectations. Here’s how OEMs are shaping the future of sandwich presses for a global audience.

The cornerstone of any successful OEM solution lies in versatility. By designing sandwich presses that can operate on both 120V and 240V electrical systems, OEMs ensure that their products are not limited by regional power supply differences. This dual voltage capability opens up a vast international market, from North America to Europe, Asia, and beyond, where power standards vary significantly.

Customization is key in the OEM world. Global customers have unique tastes and requirements, and OEMs that can offer tailor-made solutions stand out. Whether it’s adjusting the size of the sandwich press to accommodate local bread sizes or integrating specific features that cater to local dietary trends, OEMs are at the forefront of creating products that are not only functional but also culturally relevant.

Innovation isn’t just about the product itself; it’s also about the experience. OEMs are investing in user-friendly interfaces, intuitive controls, and stylish designs that appeal to a broad demographic. By focusing on these aspects, OEMs can create sandwich presses that not only perform well but also enhance the consumer’s cooking experience, making it more enjoyable and less intimidating.

Quality control is paramount in the OEM process. The global market demands reliability and durability, and OEMs that prioritize rigorous testing and adherence to international safety standards can gain a competitive edge. This includes ensuring that all components meet the highest quality standards, from the heating elements to the non-stick surfaces, to guarantee long-lasting performance.

The rise of e-commerce has changed how consumers interact with products, and OEMs are adapting by offering sandwich presses that are easy to ship and package. Lightweight materials, compact designs, and robust construction all contribute to a product that can withstand the rigors of international shipping while still arriving in perfect condition at the customer’s doorstep.

Sustainability is a growing concern worldwide, and OEMs are responding by integrating eco-friendly practices into their manufacturing processes. This includes sourcing materials that are recyclable or biodegradable, as well as designing products that are energy-efficient, reducing the carbon footprint for both the manufacturer and the end-user.

Collaboration with local partners is essential for OEMs looking to enter new markets. By working with local distributors, retailers, and even chefs, OEMs can gain valuable insights into local trends and preferences. This collaborative approach allows for the creation of products that are not only innovative but also resonate with the local culture and cooking habits.

Marketing strategies are also a critical component of OEM solutions. Global brands rely on OEMs to provide marketing materials, branding guidelines, and even training programs for sales teams. This ensures that the product launch is executed seamlessly, with consistent messaging and branding across all channels.

As the world becomes more connected, the demand for global products has never been higher. OEMs that can offer innovative, versatile, and high-quality sandwich presses are well-positioned to capture this demand. From the design phase to the final product, every aspect of the OEM process is a testament to the commitment to meeting the needs of a global customer base.

The integration of smart technology is another area where OEMs are leading the charge. By incorporating features like temperature control, timer settings, and even Bluetooth connectivity for remote operation, OEMs are not just creating sandwich presses; they are crafting smart kitchen appliances that can be integrated into the modern, tech-savvy home.

Lastly, the ability to quickly adapt to market changes is a hallmark of successful OEMs. Whether it’s a shift in consumer preferences, technological advancements, or regulatory changes, OEMs that can pivot and innovate swiftly will continue to be at the forefront of the sandwich press industry. This agility ensures that the products they supply to global customers remain cutting-edge and competitive.

The 120V/240V sandwich press has emerged as a versatile and sought-after appliance in the culinary world. Let’s delve into the advantages that make this dual voltage model stand out.

Its universal compatibility is a game-changer. The ability to operate on both 120V and 240V power sources means that the 120V/240V sandwich press is perfect for global markets. This feature eliminates the need for voltage converters or transformers, ensuring seamless operation no matter where it’s used.

The flexibility of the dual voltage model is not just about compatibility; it also allows for efficient energy use. In regions where 240V is the standard, the sandwich press can operate at a higher power output, resulting in quicker cooking times and potentially lower energy consumption compared to its 120V counterparts.

Durability is another advantage that cannot be overlooked. The design of these presses often incorporates robust materials and construction techniques to withstand the demands of various voltage levels. This means that the 120V/240V sandwich press is not only a reliable choice but also a long-lasting investment for any commercial kitchen.

Users also benefit from consistent performance. Whether in a high-powered 240V environment or a standard 120V setting, the sandwich press delivers consistent pressure and temperature control, ensuring that every sandwich is cooked to perfection.

Innovation in heating elements is a key feature of the 120V/240V sandwich press. Modern models often incorporate advanced heating technology that provides even heat distribution across the entire surface of the press. This not only ensures that the sandwich is uniformly cooked but also prevents hot spots that can lead to uneven browning or burning.

Customization is a significant advantage that OEMs offer for the 120V/240V sandwich press. Businesses can tailor the design to their specific needs, whether it’s a different size, additional features, or even a unique branding. This level of customization ensures that the sandwich press not only fits into the existing kitchen setup but also enhances the overall branding and aesthetic of the establishment.

Safety is paramount in any kitchen appliance, and the 120V/240V sandwich press does not compromise on this aspect. Many models are equipped with safety features such as automatic shut-off mechanisms, overheating protection, and non-slip bases to prevent accidents and ensure peace of mind for both operators and customers.

The efficiency of the 120V/240V sandwich press is also notable. It can handle a high volume of sandwiches in a short amount of time, making it ideal for busy cafes, delis, and restaurants. This efficiency translates into increased productivity and reduced wait times for customers.

In terms of maintenance, these sandwich presses are generally easy to clean and maintain. The removable parts and non-stick surfaces make it simpler to keep the appliance in top condition, ensuring that it remains a reliable tool in the kitchen.

The environmental impact of kitchen appliances is a growing concern, and the 120V/240V sandwich press addresses this by being energy-efficient. By using less energy and providing quick cooking times, it contributes to a more sustainable kitchen operation.

The versatility of the 120V/240V sandwich press is also evident in its ability to handle a wide range of ingredients. From traditional ham and cheese to exotic combinations, this press can cater to diverse tastes and preferences, making it a dynamic addition to any menu.

In conclusion, the 120V/240V sandwich press offers numerous advantages that cater to the needs of global customers. Its dual voltage capability, durability, consistent performance, innovative heating technology, customization options, safety features, efficiency, ease of maintenance, environmental benefits, and versatility make it an exceptional choice for any kitchen looking to serve delicious sandwiches.

In the ever-evolving landscape of kitchen appliances, the sandwich press has become a staple in homes and commercial kitchens alike. The market for sandwich presses is not just growing; it’s transforming with new trends and consumer preferences shaping the industry. Let’s delve into the current market trends and the evolving tastes of consumers in the sandwich press sector.

The demand for convenience and speed in meal preparation has surged, and the sandwich press has become a symbol of both. Consumers are looking for appliances that can quickly transform simple ingredients into a satisfying meal. This trend has led to a rise in compact, easy-to-use sandwich presses that can be used in small kitchens or on the go.

Smart features are no longer a luxury but an expectation. Modern sandwich presses often come equipped with digital controls, adjustable heat settings, and even Bluetooth connectivity for remote monitoring. These features not only enhance the user experience but also cater to the tech-savvy consumer who appreciates integration with their smart home ecosystem.

Health and wellness are at the forefront of consumer choices, and the sandwich press market is responding with healthier options. There’s a growing preference for sandwich presses that allow for the cooking of sandwiches with minimal oil or fat, promoting healthier eating habits. This shift is also reflected in the popularity of non-stick surfaces and materials that are free from harmful chemicals.

Customization is key in the sandwich press sector. Consumers are looking for appliances that can cater to their specific tastes and dietary needs. This includes a variety of press sizes to accommodate different types of bread and fillings, as well as presses that can handle different cooking temperatures for a range of sandwich styles. The ability to create gourmet sandwiches at home has become a significant draw for many.

Eco-consciousness is also influencing the sandwich press market. As consumers become more environmentally aware, there’s a trend towards appliances that are energy-efficient and made from sustainable materials. This includes presses that use less power and are designed with a focus on longevity, reducing the need for frequent replacements.

The rise of social media and influencer culture has had a profound impact on the sandwich press market. Consumers are influenced by the visually appealing content they see online, leading to a surge in demand for sandwich presses that can produce impressive results. The ability to share photos and videos of homemade gourmet sandwiches has become a significant factor in the popularity of certain models.

In terms of design, there’s a shift towards sleek, modern aesthetics. Consumers are drawn to sandwich presses that not only perform well but also look stylish in the kitchen. The rise of minimalist designs and the use of high-quality materials like stainless steel and glass have become a hallmark of the industry’s latest offerings.

Globalization has also played a role in shaping the sandwich press market. As cultures blend and international cuisine becomes more accessible, there’s an increasing demand for sandwich presses that can handle a variety of breads and fillings from around the world. This has led to the development of presses that can handle different types of bread, from traditional sliced loaves to artisanal sourdoughs.

Lastly, the market is seeing a rise in niche products that cater to specific consumer groups. For example, there are sandwich presses designed for vegan and vegetarian diets, gluten-free options, and even models that can be used to cook other types of food like omelets and pancakes. This specialization reflects the diverse and evolving preferences of consumers in the sandwich press sector.

In conclusion, the sandwich press market is dynamic and responsive to the changing needs and tastes of consumers. From convenience and smart features to health, sustainability, and customization, the industry is adapting to meet the demands of a modern, health-conscious, and visually oriented consumer base.

In the competitive landscape of the sandwich press industry, Original Equipment Manufacturers (OEMs) play a pivotal role in providing tailored solutions to meet the diverse needs of global customers. From sleek and modern designs to robust functionality, here’s a closer look at the design and customization services that OEMs can offer:

The first aspect that OEMs focus on is aesthetic appeal. Customers across the globe have varying tastes and preferences when it comes to kitchen appliances. OEMs understand this and offer a range of design options that cater to different markets. From minimalist and sleek stainless steel finishes to vibrant colors that appeal to a younger demographic, the design flexibility allows OEMs to create sandwich presses that resonate with a wide audience.

Functionality is another key area where OEMs excel. The ability to adjust cooking temperatures and pressure is crucial for perfecting the sandwich texture and taste. OEMs provide a variety of control systems, from simple dials to digital interfaces, ensuring that users can achieve their desired outcomes with ease. These systems often come with features like automatic shut-off, temperature control, and adjustable press intensity, making the sandwich-making experience more intuitive and enjoyable.

Customization extends beyond just the visual and functional aspects. OEMs offer services that cater to specific market requirements, such as compliance with local electrical standards. For instance, the 120V/240V dual voltage capability of a sandwich press is a significant customization that allows the appliance to be used in countries with different electrical systems. This ensures that the product is not only versatile but also safe and reliable for users in various regions.

Personalization is also a key offering. OEMs can incorporate brand logos, specific color schemes, or even unique features requested by the customer. This level of customization is particularly appealing to businesses looking to create a cohesive brand image across their product line. By allowing customers to imprint their brand on the sandwich press, OEMs help businesses stand out in a crowded market.

Safety is a non-negotiable factor in the kitchen appliance industry, and OEMs prioritize this in their design and customization services. They ensure that all sandwich presses meet international safety standards and regulations. This includes features like non-slip bases, secure locking mechanisms, and clear instructions for use. By focusing on safety, OEMs provide peace of mind to both the customers and the end-users.

Innovation is at the heart of what OEMs offer. They stay abreast of the latest technology and incorporate it into their products. This might involve integrating smart technology, such as Bluetooth connectivity for remote control, or using eco-friendly materials to reduce the carbon footprint of the sandwich press. By offering innovative solutions, OEMs help customers keep their products ahead of the curve.

Another area where OEMs shine is in the manufacturing process. They have the capability to scale production to meet high demand, ensuring that customers receive their customized sandwich presses on time. This includes efficient supply chain management and quality control measures that guarantee the consistency and reliability of the final product.

Customization also involves considering the user experience. OEMs understand that the sandwich press is not just a kitchen tool but a part of the cooking process. They offer user-friendly interfaces and intuitive controls that make the appliance accessible to a broad range of users, from beginners to seasoned chefs.

Lastly, OEMs provide comprehensive after-sales support. This includes customer service hotlines, maintenance guides, and replacement parts. By offering robust support systems, OEMs ensure that their customers have a seamless experience from purchase to use and beyond.

In conclusion, the design and customization services offered by OEMs in the sandwich press sector are comprehensive and cater to the specific needs of global customers. From aesthetic choices to functional enhancements, safety considerations, innovation, and user experience, OEMs are dedicated to providing tailored solutions that not only meet but exceed customer expectations.

In the world of kitchen appliances, the 120V/240V sandwich press has emerged as a versatile and sought-after product. Let’s delve into some case studies that showcase the successful implementations of these dual-voltage sandwich presses in various markets and applications.

Case Study 1: A Restaurant Chain’s Global ExpansionA renowned fast-food chain was looking to expand its menu internationally, but they faced a significant challenge: the inconsistency in electrical standards across different countries. By integrating a 120V/240V sandwich press into their new locations, the restaurant was able to ensure consistent cooking temperatures and quality, regardless of the local power supply. This dual-voltage feature was crucial in maintaining their brand’s standards worldwide.

Case Study 2: A Culinary School’s Innovation LabA prestigious culinary school needed a compact and efficient appliance for their innovation lab. The students were experimenting with various sandwich recipes, and the need for a reliable sandwich press was paramount. The dual-voltage capability of the sandwich press allowed the school to conduct tests without worrying about voltage fluctuations, ensuring that the culinary creations were consistent and delicious.

Case Study 3: A Home Chef’s Professional KitchenA professional home chef wanted to replicate the quality of restaurant-grade sandwiches in their own kitchen. The chef’s previous sandwich press only operated on a single voltage, which limited their ability to experiment with different recipes and cooking techniques. By switching to a 120V/240V sandwich press, the chef could now explore a wider range of recipes, resulting in a more diverse and impressive menu.

Case Study 4: A Mobile Catering ServiceA mobile catering service that operates in various venues often encountered different electrical outlets, making it difficult to find a sandwich press that would work universally. The company invested in a dual-voltage sandwich press, which not only simplified their setup process but also improved the efficiency of their service. The sandwich press’s reliability became a key factor in their ability to cater to events with ease.

Case Study 5: A Gourmet Food Truck’s Menu ExpansionA gourmet food truck owner was looking to add a new dimension to their menu with a variety of gourmet sandwiches. The challenge was to find a sandwich press that could handle the demands of their mobile kitchen environment. The dual-voltage sandwich press provided the flexibility needed to cook a range of breads and fillings, from traditional to exotic, without compromising on quality or consistency.

Case Study 6: A Health Food Store’s Deli CounterA health food store with a deli counter needed a sandwich press that could cater to both low-sodium and gluten-free diets. The dual-voltage sandwich press allowed them to toast a variety of breads and wraps without the risk of burning, ensuring that each customer received a perfect sandwich. The appliance’s versatility became a selling point for their store, attracting health-conscious customers.

Case Study 7: A Catering Company’s Event PreparationsA catering company that specializes in large-scale events often faced the challenge of providing high-quality sandwiches to a crowd. The 120V/240V sandwich press became an essential tool in their arsenal, enabling them to prepare sandwiches in bulk while maintaining the integrity of the ingredients. The appliance’s durability and consistent performance were crucial in meeting the demands of high-pressure catering situations.

In each of these case studies, the 120V/240V sandwich press played a pivotal role in enhancing the functionality, efficiency, and customer satisfaction of various businesses. From international restaurants to mobile food services and gourmet food trucks, the dual-voltage feature has proven to be a game-changer in the sandwich press market. These case studies not only highlight the practical benefits of using such a versatile appliance but also underscore the importance of innovation and adaptability in the foodservice industry.

In the evolving landscape of the sandwich press industry, the introduction of 120V/240V dual voltage models has opened up a world of possibilities for both manufacturers and consumers. These versatile appliances have become a staple in various markets, from commercial kitchens to home bakeries, and even in international settings where voltage standards differ. Let’s delve into some of the key insights into the future of this sector.

The global market for sandwich presses is experiencing a surge in demand, driven by several factors. One of the most significant is the rise of fast-casual dining. With the trend of quick, yet high-quality meals on the rise, sandwich presses have become a crucial tool for creating delectable sandwiches in a fraction of the time it would take to prepare them traditionally. This shift has led to a demand for presses that can handle the rigors of a busy kitchen environment, making dual voltage models particularly appealing.

Consumers, too, are gravitating towards dual voltage sandwich presses for their convenience and adaptability. Whether they’re traveling abroad or living in regions with different voltage systems, these presses offer the flexibility to be used anywhere. This has not only expanded the customer base but has also led to a surge in online sales, as more people seek out these versatile appliances for their personal use.

Looking ahead, there are several projections that could shape the future of the sandwich press industry. One of the most notable trends is the integration of smart technology. As the world becomes more connected, appliances that can be controlled remotely or through smartphone apps are becoming increasingly popular. For instance, a sandwich press with a built-in timer or temperature control could become a game-changer for both commercial and domestic users.

Another projection involves the customization of sandwich presses to cater to specific dietary needs. With the growing demand for gluten-free, vegan, and other specialized diets, OEMs (Original Equipment Manufacturers) are likely to see a rise in requests for presses that can accommodate these unique requirements. This could include adjustable heating elements to ensure even cooking for various ingredients, or even presses with detachable parts for easy cleaning and maintenance.

While the future of the sandwich press industry is bright, it’s not without its challenges. One of the primary hurdles is the need for compliance with various international safety standards. Dual voltage appliances must meet the stringent requirements of different countries, which can be both costly and time-consuming for manufacturers. Additionally, the rapid pace of technological advancements means that OEMs must stay ahead of the curve to remain competitive.

Innovation is also a significant challenge, as the sandwich press market is becoming increasingly saturated. OEMs must find ways to differentiate their products, whether through unique design, enhanced functionality, or sustainability efforts. This could involve using eco-friendly materials, reducing energy consumption, or even incorporating features that promote a healthier lifestyle, such as sandwich presses that can toast bread without the risk of burning.

Another challenge lies in the distribution of these products. With the rise of e-commerce, OEMs must adapt to an environment where customers expect fast and reliable shipping. This requires efficient logistics and a robust supply chain, which can be difficult to manage, especially for companies that operate on a global scale.

Despite these challenges, the opportunities in the sandwich press industry are vast. As consumer preferences continue to evolve, so too will the offerings from OEMs. The key will be for manufacturers to stay agile, responsive, and innovative, ensuring that their products meet the demands of the modern market.

In conclusion, the sandwich press industry is poised for significant growth, with dual voltage models leading the charge. As the industry navigates the complexities of global markets, technological advancements, and consumer expectations, the focus on design, customization, and sustainability will be paramount. By rising to these challenges, OEMs can not only survive but thrive in an industry that is rapidly evolving.

The versatility of sandwich press technology has revolutionized the way we enjoy our meals, both at home and on the go. As the industry continues to evolve, it’s important to acknowledge the innovations that have made this possible. From the convenience of dual voltage options to the personalized touch of customization, the journey of sandwich presses has been marked by a series of advancements. Let’s delve into the future projections and challenges that lie ahead in this dynamic sector.

Sandwich presses have become a staple in the kitchen, offering a quick and easy way to prepare toasted sandwiches, panini, and other delicious treats. The technology has expanded to cater to a global audience, which is why the industry is increasingly focusing on dual voltage capabilities. This feature allows the appliances to operate seamlessly across various electrical standards, making them ideal for export and international markets.

In the quest for convenience, consumers are gravitating towards sandwich presses that combine efficiency with ease of use. Modern presses come with features such as non-stick surfaces, adjustable heat settings, and even programmable options for perfect cooking every time. As the industry continues to innovate, we can expect to see more advanced features that cater to the evolving preferences of consumers.

The rise of health-conscious eating habits has also influenced the sandwich press market. People are seeking healthier options, and sandwich presses offer a way to control the ingredients and cooking methods. This has led to an increase in the demand for non-toxic materials, such as stainless steel and ceramic, which are free from harmful chemicals like PFOA and PFAS.

Another trend worth noting is the growing interest in customization. Consumers are not only looking for quality and functionality but also for products that reflect their personal style. OEMs are responding by offering a variety of designs, from sleek and modern to classic and vintage. Customization extends beyond aesthetics; it also includes the ability to tailor the press to specific cooking requirements, such as adjustable pressure or unique bread-toasting patterns.

Despite the positive developments in the sandwich press industry, there are challenges that need to be addressed. One of the most significant is the need for energy efficiency. As environmental concerns become more pronounced, it’s crucial for OEMs to produce appliances that are not only energy-saving but also environmentally friendly. This could involve using more sustainable materials, optimizing energy consumption, and reducing waste during production.

Regulatory compliance is another area that presents challenges. Different countries have varying safety and quality standards, and OEMs must navigate these complexities to ensure their products meet global requirements. This can be particularly challenging when dealing with dual voltage appliances, as they must be tested and certified for use in various electrical systems.

The rise of e-commerce has also brought about new challenges. While it has expanded the market reach for sandwich presses, it has also increased competition. OEMs must now not only focus on the quality and features of their products but also on the packaging, branding, and online marketing strategies to stand out in a crowded marketplace.

In terms of future projections, one can anticipate that the sandwich press industry will continue to grow, driven by technological advancements and changing consumer behaviors. The integration of smart technology is already gaining traction, with presses that can be controlled remotely or through mobile apps. This trend is likely to continue, as consumers become more tech-savvy and seek ways to incorporate smart kitchen appliances into their daily routines.

Moreover, the industry may see a shift towards modular designs that allow for easy upgrades and repairs. This would address the challenge of longevity and sustainability by extending the lifespan of the product and reducing waste.

In conclusion, the sandwich press industry is ripe with opportunities and challenges. Embracing versatility, whether in terms of dual voltage, design, or functionality, is key to staying ahead in this dynamic market. As OEMs continue to innovate and adapt to consumer needs, they must also navigate the complexities of global regulations, energy efficiency, and the competitive landscape of e-commerce. By doing so, they can ensure that sandwich presses remain a beloved kitchen staple for years to come.