Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving culinary landscape, the rise of the industrial panini press has quietly become a game-changer for commercial kitchens. This versatile appliance has not only transformed the way sandwiches are made but has also opened up a world of possibilities for chefs and restaurateurs alike. As we delve into the intricacies of this innovative technology, it becomes clear why the industrial panini press is not just a trend but a necessity for any professional kitchen.

The culinary world has been abuzz with a new trend that’s reshaping the way we think about kitchen appliances: industrial panini presses. Once a staple in the realm of casual eateries and home kitchens, these versatile appliances have now taken a leap into the professional culinary scene, becoming a game-changer in the kitchen.

With their ability to deliver consistent, high-quality sandwiches in a matter of minutes, industrial panini presses have quickly become a favorite among chefs and foodservice operators. The demand for these robust machines has surged, as they offer a unique blend of speed, efficiency, and precision that is hard to match.

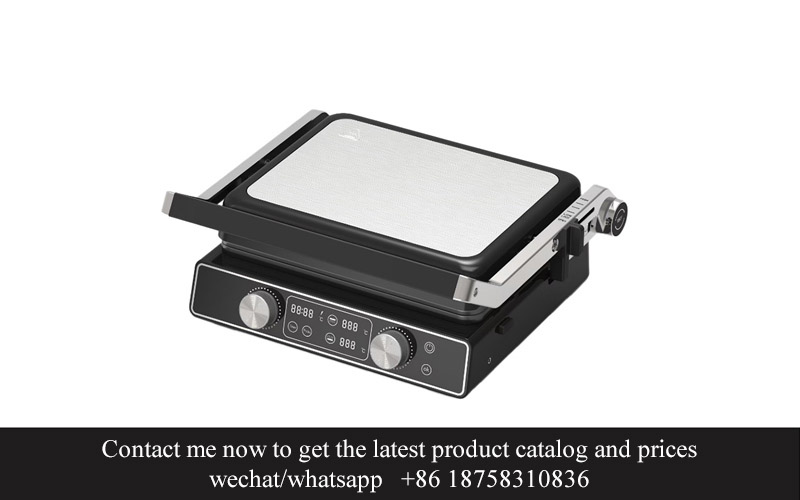

The secret to their popularity lies in their design. Industrial panini presses are built to withstand the rigors of commercial use, featuring heavy-duty construction and durable materials that ensure longevity. Their oversized plates can accommodate larger portions, making them perfect for busy restaurants and catering services. Moreover, the adjustable pressure settings allow for customization, ensuring that every sandwich is cooked to perfection.

One of the standout features of these presses is their ability to lock in flavors and juices, resulting in a moist and flavorful panini every time. This is particularly beneficial for establishments serving a variety of sandwiches, as it allows for the preservation of each ingredient’s distinct taste. Chefs are now able to create gourmet sandwiches that are as visually appealing as they are delicious.

The rise of industrial panini presses can also be attributed to the evolving consumer preferences. As health consciousness and convenience become increasingly important, diners are seeking out restaurants that offer quick, yet satisfying meals. Industrial panini presses fit this bill perfectly, as they can churn out a large number of sandwiches in a short amount of time without compromising on quality.

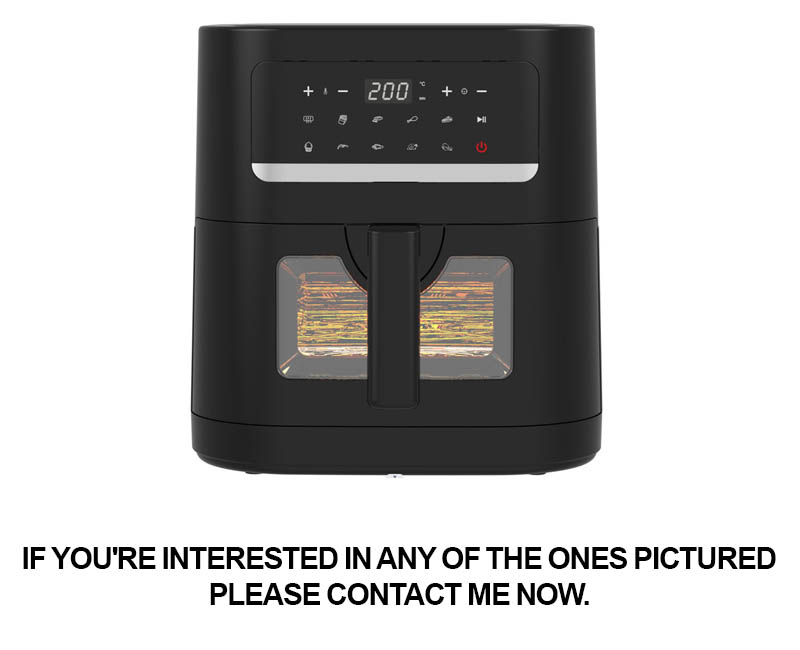

Another factor contributing to the surge in popularity is the versatility of these presses. Beyond sandwiches, they can be used to cook a variety of other items, such as flatbreads, wraps, and even some main dishes. This adaptability has made them a must-have in kitchens that want to offer a diverse menu without the need for multiple appliances.

In the commercial kitchen, time is of the essence. Industrial panini presses save valuable minutes by streamlining the cooking process. Chefs can focus on other aspects of food preparation, ensuring that the entire kitchen operates smoothly. This efficiency is not just a benefit for the kitchen staff; it also translates into cost savings for the business, as less energy is required to cook larger quantities of food.

As the demand for industrial panini presses grows, manufacturers are responding by introducing new models with advanced features. Some presses now come with programmable settings, allowing chefs to set specific temperatures and cooking times for different types of sandwiches. Others are equipped with non-stick surfaces that make cleaning a breeze and ensure that each sandwich is free from unwanted residue.

The market for industrial panini presses is also being influenced by the rise of food trucks and pop-up restaurants. These mobile operations require lightweight, portable appliances that can be easily transported and set up. Industrial panini presses fit this criterion perfectly, making them a popular choice for entrepreneurs looking to establish a presence in the dynamic foodservice industry.

In conclusion, the rise of industrial panini presses is a testament to the ever-evolving needs of the culinary world. These appliances have proven to be a valuable asset in commercial kitchens, offering speed, efficiency, and versatility that can elevate the quality of a restaurant’s menu. As the trend continues to gain momentum, it’s clear that the industrial panini press is here to stay, becoming an indispensable tool in the modern kitchen.

The industrial panini press has emerged as a powerhouse in the culinary world, transforming the way we think about sandwiches. This robust piece of equipment is designed for high-volume cooking, making it an essential tool for restaurants, delis, and food trucks. Let’s delve into what sets the industrial panini press apart and why it’s becoming such a crucial component in commercial kitchens.

With a sleek, durable design, these presses are built to withstand the rigors of continuous use. Unlike their consumer-grade counterparts, industrial panini presses are crafted from heavy-duty materials like stainless steel, ensuring they can handle the demands of a busy kitchen environment. Their sturdy construction not only guarantees longevity but also maintains the integrity of the cooking process.

The heating elements within an industrial panini press are strategically placed to distribute heat evenly across the entire surface. This even heat distribution is crucial for achieving that perfect sear on the bread while keeping the fillings juicy and warm. Whether you’re grilling a classic ham and cheese sandwich or creating a gourmet fusion creation, the precision of these presses ensures consistent results.

One of the standout features of industrial panini presses is their adjustable pressure. Unlike the single-pressure models found in home kitchens, these commercial-grade presses offer a range of pressure settings. This versatility allows chefs to tailor the cooking experience to the type of bread and filling, ensuring that each sandwich is cooked to perfection. For instance, a thick ciabatta may require more pressure to achieve a crispy crust, while a delicate baguette might need less to prevent overcooking.

In terms of size, industrial panini presses come in various dimensions to accommodate different kitchen layouts and needs. From compact models perfect for countertop spaces to larger units designed for full-service restaurants, there’s an industrial panini press to fit every kitchen. The larger presses often have multiple cooking surfaces, allowing for multiple sandwiches to be cooked simultaneously, significantly reducing wait times and increasing efficiency.

Another key advantage of industrial panini presses is their ability to cook a variety of foods beyond sandwiches. Many models are versatile enough to grill vegetables, toast bread, and even prepare flatbreads. This multipurpose functionality adds value to the kitchen, allowing for a wider menu selection without the need for additional equipment.

Safety is a top priority in commercial kitchens, and industrial panini presses are equipped with features that prioritize operator safety. Some models come with safety interlocks that prevent the lid from closing if an object is obstructing the path, reducing the risk of accidents. Additionally, the heat-up time for these presses is typically faster than residential models, allowing for quicker use and less downtime between cooking sessions.

Ease of maintenance is another critical factor in commercial kitchen equipment. Industrial panini presses are designed with easy-to-clean surfaces and removable parts, making them a breeze to clean after a busy service. This not only ensures that the equipment remains in optimal condition but also contributes to maintaining high hygiene standards in the kitchen.

The rise of the industrial panini press is also reflective of changing consumer preferences. As the demand for fast, delicious, and customizable meals continues to grow, these presses allow operators to meet these expectations. The ability to quickly prepare a wide array of sandwiches means that customers can enjoy their favorite comfort food without the wait.

Moreover, the market for industrial panini presses is witnessing innovative advancements. New technologies are being integrated into these machines, such as digital temperature control, which allows for even more precise cooking. Some models even come with programmable settings, making it possible for chefs to save their preferred cooking parameters for quick access.

In conclusion, the industrial panini press is more than just a sandwich maker; it’s a game-changer in the commercial kitchen. Its robust design, precise heat distribution, adjustable pressure, and versatile cooking capabilities make it an invaluable tool for any establishment looking to offer high-quality sandwiches and a variety of other culinary delights. As the culinary landscape continues to evolve, the industrial panini press stands as a testament to the power of innovation in the foodservice industry.

In the ever-evolving world of kitchen appliances, the industrial panini press has emerged as a powerhouse of innovation. These presses, once a staple in the casual dining sector, have now transcended their boundaries to become essential tools in high-volume kitchens. Let’s delve into the latest design innovations that have set the industry abuzz.

The sleek and modern aesthetics of the latest industrial panini presses are a testament to their evolution. No longer are they just utilitarian machines; they are now sleek, with stainless steel exteriors and ergonomic handles that not only enhance the look but also make them a pleasure to use. The smooth surfaces are not just for show; they are easy to clean, a crucial factor in a commercial kitchen environment.

One of the standout features of modern industrial panini presses is their variable temperature control. With precise digital displays, chefs can set the exact temperature needed for different types of sandwiches, ensuring consistency and quality every time. This level of control is a game-changer, allowing for a wider variety of recipes to be crafted, from classic ham and cheese to gourmet creations with complex flavor profiles.

The design of the heating plates has also seen significant advancements. Many new models come with non-stick surfaces that not only prevent food from sticking but also make cleaning a breeze. The plates are often made from high-quality materials that can withstand intense heat, ensuring long-lasting durability. Some presses even feature adjustable pressure plates, allowing for the perfect amount of compression on the sandwiches, which is essential for achieving that perfect golden-brown crust.

Safety features have been a major focus in the design of these industrial presses. Auto shut-off functions are now standard, providing peace of mind that the machine will turn off if left unattended or when the desired cooking time has elapsed. This not only prevents accidents but also saves energy. Additional safety features include cool-touch handles and surfaces, reducing the risk of burns during use.

Efficiency is a key consideration in the design of industrial panini presses. Many models now come with rapid heat-up capabilities, reducing the time it takes to start cooking from cold. This is especially important in busy kitchens where every second counts. Some presses also feature rapid cool-down features, allowing them to be used continuously without the need for lengthy cooling periods between uses.

The build quality of these presses is exceptional. Robust construction, with heavy-duty frames and hinges, ensures that these machines can withstand the rigors of a commercial kitchen. The use of high-quality components means that these presses are not only durable but also reliable, with minimal maintenance required.

In terms of functionality, the latest industrial panini presses offer a range of innovative features. Some models come with adjustable cooking surfaces, allowing them to accommodate different sizes of sandwiches, from single-serving to large, family-sized portions. Others include features like adjustable heat zones, which can be set to different temperatures for cooking multiple types of food simultaneously.

The design of the cooking surface has also been refined. Many presses now feature a surface that is both flat and textured, which is perfect for creating a variety of sandwich styles. The textured surface can help lock in moisture, ensuring that the bread is crispy on the outside and soft on the inside.

Another interesting innovation is the inclusion of LED lighting. This feature not only illuminates the cooking surface for better visibility but also adds a touch of modernity to the design. It also helps in monitoring the cooking process, ensuring that the sandwich is cooked evenly.

Finally, the design of industrial panini presses has become more user-friendly. The placement of controls is intuitive, and the overall layout of the machine is designed to minimize clutter and simplify operation. This makes it easier for kitchen staff to use the presses efficiently, without unnecessary downtime.

In conclusion, the design of industrial panini presses has come a long way, incorporating innovations that enhance safety, efficiency, and ease of use. These features make these machines not just a necessity in commercial kitchens but also a source of inspiration for chefs looking to create exceptional sandwiches.

In recent years, the demand for industrial panini presses has surged, reflecting a shift in consumer preferences and the evolving needs of the foodservice industry. This section delves into the factors driving this growth and the implications it has for manufacturers and end-users alike.

The rise of fast-casual dining has played a significant role in fueling the demand for industrial panini presses. As consumers seek quick yet satisfying meals, restaurants and cafes are increasingly offering panini sandwiches as part of their menu. These establishments require robust, high-volume equipment to keep up with the demand, making industrial panini presses a necessity.

The convenience of panini sandwiches has also contributed to their popularity. They are easy to prepare, require minimal ingredients, and can be customized to cater to various dietary preferences. This versatility has made them a staple in both casual and upscale dining settings, further spiking the demand for commercial-grade panini presses.

Moreover, the health consciousness of modern consumers has led to a preference for fresh, unprocessed foods. Panini sandwiches, often made with fresh bread and fillings, align perfectly with this trend. As a result, operators are investing in industrial panini presses to offer these healthier options to their customers.

The rise of food trucks and pop-up restaurants has also impacted the market. These mobile operations need portable, efficient cooking equipment that can be easily transported and set up. Industrial panini presses fit this bill, providing a reliable solution for operators looking to expand their offerings without a permanent kitchen space.

From a technological standpoint, advancements in panini press design have made them more appealing. Modern models feature non-stick surfaces that reduce the need for oil, ensuring healthier sandwiches. Some models even come with adjustable heat settings, allowing for precise control over cooking temperatures, which is crucial for achieving the perfect texture and flavor.

The demand for energy-efficient appliances has also influenced the market. With rising energy costs and environmental concerns, restaurants are seeking out equipment that consumes less power. Industrial panini presses that meet these criteria are becoming more sought after, as they help businesses lower their operational expenses and reduce their carbon footprint.

The trend towards international cuisine has expanded the market for industrial panini presses as well. As more cultures are embraced in the culinary world, the variety of panini-style sandwiches has grown. From Italian-inspired caprese to Japanese-style teriyaki, these presses enable chefs to create a wide array of international dishes, further boosting demand.

The retail sector has also contributed to the growth in industrial panini presses. Home chefs and hobbyists are increasingly interested in replicating the flavors and textures of professional-grade panini sandwiches. As a result, there’s a growing market for high-quality, yet affordable, industrial panini presses designed for home use.

The rise of e-commerce has made it easier for businesses to reach new customers and for consumers to access a wider range of products. Online retailers are capitalizing on this trend by offering a variety of industrial panini presses, often with detailed product descriptions and customer reviews, which helps to inform and influence purchasing decisions.

Lastly, the demand for convenience and speed in food preparation is relentless. With the fast-paced lifestyle of today’s society, the ability to cook a delicious panini in mere minutes is a major draw for both operators and consumers. Industrial panini presses are perfectly positioned to meet this need, making them an indispensable tool in the modern kitchen.

In conclusion, the growing demand for industrial panini presses is a multifaceted phenomenon, driven by a combination of factors including the popularity of fast-casual dining, health trends, technological advancements, and the evolving culinary landscape. As these trends continue to shape the foodservice industry, the demand for these versatile appliances is expected to remain robust, offering manufacturers and operators numerous opportunities for growth and innovation.

The commercial kitchen landscape is constantly evolving, and one of the latest trends to take hold is the integration of industrial panini presses. These robust appliances are not just for making quick sandwiches anymore; they’re revolutionizing the way chefs and restaurateurs approach food preparation and service. Here’s how:

The Efficiency of High-Volume ProductionIndustrial panini presses are designed to handle the rigors of high-volume production. With their large, flat surfaces and powerful heat elements, these machines can cook multiple sandwiches at once, significantly reducing the time it takes to serve a large number of customers. This efficiency is a game-changer for busy restaurants, cafes, and food trucks that need to maintain a steady stream of orders without compromising on quality.

Customization at ScaleOne of the standout features of modern industrial panini presses is their ability to customize sandwiches to order. With adjustable temperature controls and heating elements that can reach high temperatures quickly, these presses can cater to a variety of dietary preferences and restrictions. From vegan to gluten-free, the options are endless, and the speed at which these presses can cook ensures that each customer gets their perfect sandwich, every time.

Enhanced Cooking UniformityIn the past, achieving a perfectly toasted sandwich with even coloring and crispness on both sides was a challenge. Industrial panini presses have solved this problem with their even heat distribution. The consistent cooking temperature means that every sandwich comes out with the desired level of crispness and texture, which is crucial for maintaining a high standard of food quality in a commercial setting.

Reduced Labor CostsThe speed and efficiency of industrial panini presses can also lead to significant labor cost savings. By automating the cooking process, these machines can reduce the need for a large staff to handle the sandwich-making tasks. Chefs and kitchen staff can focus on other aspects of food preparation, or even on customer service, which can enhance the overall dining experience.

Versatility Beyond SandwichesWhile industrial panini presses are excellent for making sandwiches, their versatility extends beyond just toasted fare. They can be used to cook wraps, paninis, and even some main dishes like grilled cheese or even flatbreads with fillings. This versatility allows restaurants to offer a wider variety of menu items without the need for additional cooking equipment.

Improved Health and SafetyCommercial kitchens are under constant scrutiny for health and safety standards. Industrial panini presses contribute to these standards by minimizing the risk of burns and cross-contamination. The non-stick surfaces and sealed cooking chambers prevent food from sticking and reduce the risk of spills, which can be a major safety concern in a busy kitchen environment.

Customer Satisfaction and Brand DifferentiationThe quality and speed of service in a restaurant can greatly impact customer satisfaction. With industrial panini presses, restaurants can offer a unique, high-quality sandwich experience that sets them apart from competitors. Satisfied customers are more likely to return and recommend the establishment to others, which can lead to increased foot traffic and revenue.

Sustainability and Energy EfficiencyAs the world becomes more environmentally conscious, commercial kitchens are looking for ways to reduce their carbon footprint. Industrial panini presses are designed with energy efficiency in mind, consuming less power than traditional cooking methods while still delivering fast and consistent results. This not only saves money on energy bills but also aligns with the values of eco-friendly dining.

In conclusion, industrial panini presses are not just a tool for making sandwiches; they are a catalyst for innovation in commercial kitchens. Their ability to handle high volumes, customize orders, ensure cooking uniformity, reduce labor costs, and offer versatility has made them a staple in modern kitchens. As the demand for quick, quality food continues to grow, these presses are set to play a pivotal role in shaping the future of the foodservice industry.

In the quest for the perfect panini, the secret often lies in the details. From selecting the right ingredients to mastering the technique, here are some expert tips to help you achieve those professional-quality results every time:

The Bread Choice: The foundation of a great panini is the bread. Opt for a high-quality, crusty loaf that can stand up to the heat and create a satisfying crunch. Consider ciabatta, sourdough, or a sturdy whole-grain bread for the best texture and flavor.

Properly Toasting the Bread: Before you even think about pressing your panini, the bread needs to be toasted. A lightly toasted outer crust ensures a crispier, more enjoyable bite. Use a panini press or a grill pan to achieve an even toast on both sides.

Perfecting the Ingredients: The beauty of a panini lies in its simplicity and the quality of its fillings. Choose fresh, high-quality ingredients, and don’t overdo it. A few slices of quality cheese, a few leaves of arugula, and a thin layer of savory meat or salami can elevate your panini from good to great.

Sealing in the Flavors: One of the key advantages of a panini press is the ability to seal in flavors and juices. As you press the sandwich, the heat and pressure help to meld the flavors together and create a more cohesive texture. Make sure to close the press all the way and maintain a consistent temperature for the best results.

Avoiding Soggy Bread: One common pitfall is a soggy, under-toasted bread. To prevent this, ensure that the ingredients are not overly wet or packed too tightly in the sandwich. Use a paper towel to absorb excess moisture from lettuce or other wet ingredients, and be careful not to overload the panini with too much filling.

The Importance of Temperature: The temperature of your panini press is crucial. Too low, and the cheese won’t melt properly, and the outside of the bread won’t get that perfect golden-brown crust. Too high, and you risk burning the outside while the inside remains cold. Find the sweet spot that works for your specific press and the type of panini you’re making.

Timing is Everything: The cooking time can vary depending on the thickness of your panini and the heat of your press. Typically, a few minutes per side should be sufficient. Keep an eye on your sandwich to ensure even cooking and to prevent burning.

Adding a Touch of Flair: For that extra bit of flair, consider adding a sprinkle of herbs or a drizzle of olive oil before pressing. It can add a delightful aroma and enhance the overall taste of the panini.

The Art of Presentation: Finally, the way you present your panini can make a big difference. Cut it diagonally for a fancy touch, or serve it open-faced to showcase the ingredients. A beautifully presented panini not only tastes great but also looks inviting and appetizing.

In conclusion, achieving professional-quality panini results is all about the balance between the right bread, quality ingredients, proper toasting, and the perfect amount of pressure and temperature. With a bit of practice and these tips, you’ll be well on your way to making mouthwatering paninis that will impress your friends and family.

In the ever-evolving world of commercial kitchen equipment, the industrial panini press has emerged as a staple, transforming the way sandwiches are prepared and served. This surge in popularity isn’t just a fleeting trend; it’s a testament to the innovation and efficiency these presses bring to the table. Let’s delve into the competitive landscape, highlighting key players and market trends that are shaping the future of the industrial panini press industry.

The rise of fast-casual dining has propelled the demand for quick and consistent food service, and industrial panini presses have become the go-to tool for achieving that perfect grilled sandwich. Brands like Nu-Wave, Breville, and Wolfgang Puck have capitalized on this demand, offering a range of high-quality presses that cater to both small cafes and bustling restaurants.

Nu-Wave, known for its cutting-edge kitchen appliances, has been a leader in the industrial panini press market. Their presses are not only durable and reliable but also feature innovative designs that enhance the cooking process. The ability to lock in flavors and achieve a perfect golden-brown crust has made Nu-Wave products a favorite among chefs.

Breville, another major player, has brought a touch of luxury to the industrial panini press market with their sleek and modern designs. Their presses are often equipped with features like adjustable heat settings and non-stick surfaces, ensuring that every sandwich is cooked to perfection. The brand’s reputation for quality and innovation has solidified its position in the competitive landscape.

Wolfgang Puck, a name synonymous with culinary excellence, has also entered the industrial panini press market. Their presses are designed with the professional chef in mind, offering precision and consistency. The brand’s commitment to quality and its association with high-end dining have made Wolfgang Puck presses a top choice for many commercial kitchens.

As the market for industrial panini presses continues to grow, so does the competition. New entrants are constantly pushing the boundaries of design and functionality, challenging established brands to innovate further. One such trend is the integration of smart technology into these presses. With features like digital temperature control and Bluetooth connectivity, these presses are becoming more than just cooking tools; they are part of a larger, interconnected kitchen ecosystem.

Market trends also show a shift towards sustainability and energy efficiency. As businesses become more environmentally conscious, they are seeking out kitchen equipment that not only performs well but also minimizes their carbon footprint. This has led to the development of energy-saving models that still deliver exceptional results.

Another significant trend is the customization of industrial panini presses. Kitchens are looking for equipment that can cater to their specific needs, whether it’s a different size of press or unique features that make their operation more efficient. This customization is not just limited to the physical design but also includes software and interface improvements that allow for easier menu management and cooking profiles.

The competitive landscape is also influenced by the global distribution of these presses. Key players are not only focusing on domestic markets but are also expanding their reach internationally. This global expansion is driven by the increasing popularity of panini sandwiches across various cultures and the desire for consistent quality in food service.

In conclusion, the competitive landscape of the industrial panini press market is dynamic and ever-changing. Key players like Nu-Wave, Breville, and Wolfgang Puck are leading the charge with innovative designs and features that cater to the demands of modern commercial kitchens. As market trends continue to evolve, we can expect to see even more advancements in technology, sustainability, and customization that will further revolutionize the way sandwiches are prepared and enjoyed around the world.

The evolution of industrial panini presses has introduced a new wave of technology that’s reshaping the way we think about sandwich-making in commercial kitchens. From high-volume operations in cafes to fast-food chains, these machines have become an indispensable tool for businesses looking to deliver a consistent, professional-quality product. Let’s delve into the impact these presses are having and what we can expect in the future.

The industrial panini press market is witnessing a surge in demand, driven by factors like convenience, customization, and health-conscious consumer trends. With this growth comes an array of advancements in design and functionality. One key feature that’s gained popularity is the adjustable heat control. This allows chefs to tailor the cooking temperature to different types of bread and fillings, ensuring a perfect sear every time.

Moreover, the integration of digital displays and programmable settings has made these presses more user-friendly. Operators can easily set and save preferred cooking temperatures and times, reducing the margin for error and ensuring a consistent output. Some models even offer temperature gradients across the pressing surface, ensuring even cooking from edge to edge.

Another significant development is the use of non-stick coatings and materials that enhance hygiene and ease of maintenance. These features not only help prevent sticking but also make the presses more durable and easier to clean. In a commercial kitchen setting, where cleanliness is paramount, these innovations are a game-changer.

The competitive landscape is bustling with key players each vying for a share of the growing market. Companies like Giga Press, Waring, and Nu-Ware have established themselves as industry leaders, offering a range of high-quality presses. They’ve managed to do so by staying abreast of market trends and investing in research and development to push the boundaries of what’s possible with these machines.

For instance, Giga Press has introduced a compact panini press designed for countertop use, perfect for cafes and small foodservice operations. Their innovative design includes a locking mechanism that keeps the press closed securely, ensuring safety for busy kitchens. On the other hand, Waring has focused on heavy-duty presses for high-volume use, with features like a removable heating element for easy cleaning and a sturdy construction that can withstand rigorous daily use.

Market trends are also evolving, with a greater emphasis on energy efficiency and sustainability. As environmental concerns become more prevalent, manufacturers are looking for ways to reduce energy consumption without compromising on performance. This has led to the development of presses with energy-saving modes and eco-friendly materials.

Looking ahead, the future of industrial panini press technology is promising. Innovations such as smart technology integration are on the horizon. Imagine a panini press that not only adjusts to different cooking settings but also communicates with kitchen management systems to optimize energy use and track usage patterns. This kind of integration could lead to more efficient operations and reduced overhead costs.

Furthermore, we might see presses that are customizable not just in terms of heat settings but also in design and features. Modular systems that allow for attachments or additional functions could become more common, providing chefs with a versatile tool that can adapt to their unique needs.

Another area of potential growth is the use of alternative energy sources. As the push for renewable energy continues, industrial panini presses could be designed to run on solar power or other sustainable energy sources, further aligning with eco-conscious practices in the foodservice industry.

Lastly, the health and wellness trend is likely to influence future innovations. We could see presses that not only offer a variety of cooking options but also incorporate features that enhance the nutritional value of the panini. For example, presses with steam injection capabilities could help lock in the natural flavors and nutrients of the ingredients, appealing to consumers who are increasingly health-conscious.

In conclusion, the future of industrial panini press technology is bright, with a focus on convenience, customization, energy efficiency, and sustainability. As the market continues to grow, we can expect to see a wealth of new features and innovations that will further revolutionize the way commercial kitchens operate.

In the fast-paced world of commercial kitchens, the demand for efficient and reliable appliances has never been higher. Among these, the industrial panini press stands out as a versatile and indispensable tool. Here’s why every professional kitchen should consider this marvel of modern cuisine.

The industrial panini press has transcended its origins as a simple grilled cheese maker. Today, it’s a cornerstone of a variety of culinary creations, from gourmet sandwiches to delectable wraps. Its ability to lock in flavors and textures makes it a favorite among chefs who value both speed and quality.

The compact design of these presses means they can easily fit into even the most cramped kitchen spaces. Unlike their residential counterparts, industrial models are built to withstand the rigors of constant use, ensuring they remain reliable year after year. This durability is a testament to the quality craftsmanship that goes into their construction.

What sets industrial panini presses apart is their precision. With adjustable heat settings and non-stick surfaces, these appliances allow for consistent results every time. Chefs can fine-tune the cooking temperature to match the specific requirements of their recipes, whether it’s a delicate melt or a perfectly toasted crust.

In the competitive landscape of commercial kitchens, the ability to offer a diverse menu is crucial. Industrial panini presses cater to this need by enabling the preparation of a wide array of items. From breakfast sandwiches to lunchtime wraps, these presses can help streamline service and reduce wait times, keeping customers satisfied and coming back for more.

The convenience of these presses is undeniable. They can cook multiple sandwiches simultaneously, which is especially beneficial during peak hours when time is of the essence. This efficiency doesn’t compromise on quality, as the even heat distribution ensures that every piece of bread is toasted to perfection.

Safety is another key factor in the design of industrial panini presses. With features like cool-touch handles and safety interlocks, these appliances protect both the chef and the customer from accidents. This peace of mind is invaluable in a kitchen environment where distractions and high-pressure situations are the norm.

In recent years, there has been a surge in the popularity of healthier eating habits. Industrial panini presses are perfectly suited to this trend, as they can be used to create nutritious and delicious sandwiches filled with fresh ingredients. This not only appeals to health-conscious customers but also supports the growing demand for sustainable and locally sourced foods.

The competitive landscape of industrial panini presses is heating up. Key players in the market are continuously innovating, offering a range of features that cater to the diverse needs of commercial kitchens. From high-volume models to those designed for specific types of bread, the options are vast.

One notable trend is the integration of smart technology. Some industrial panini presses now come with digital displays that allow for precise temperature control and timer settings. This level of customization ensures that chefs can achieve the exact results they desire with minimal effort.

Another significant development is the emphasis on sustainability. Manufacturers are exploring eco-friendly materials and energy-efficient designs to reduce the environmental impact of their products. This shift aligns with the broader movement towards sustainability in the foodservice industry.

Looking ahead, the future of industrial panini press technology is bright. Innovations such as self-cleaning features, enhanced durability, and even more precise temperature control are on the horizon. These advancements will not only make the appliances more convenient but also more cost-effective for businesses.

In conclusion, the industrial panini press is more than just a kitchen gadget; it’s a game-changer. Its ability to enhance the efficiency, quality, and variety of a commercial kitchen’s offerings is undeniable. For any professional kitchen looking to stay ahead of the curve, investing in an industrial panini press is a no-brainer. It’s not just a tool—it’s a key component of a successful and dynamic kitchen operation.