Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Ah, the humble sandwich press—once a simple kitchen gadget, now a beacon of innovation and culinary craftsmanship. It’s more than just a tool to cook a perfectly toasted sandwich; it’s a symbol of the evolution in the way we approach our meals. In this article, we delve into the world of heavy-duty sandwich presses, exploring their unique features, the cutting-edge technologies behind their production, and where to find the very best among them. We’re here to turn your sandwich-making dreams into reality.

The Heavy Duty Sandwich Press has quietly but firmly established itself as a game-changer in the kitchen, transforming the way we approach sandwich-making. Once a niche product, it has now become a staple in many households and commercial kitchens alike. Let’s delve into the fascinating journey of this kitchen marvel.

These robust sandwich presses have seen a surge in popularity due to their ability to lock in the perfect amount of crispiness on both sides of a sandwich, ensuring a delightful textural contrast. Whether you’re a fan of toasted cheese or gourmet sliders, this kitchen gadget has something to offer every foodie.

The demand for a superior, durable sandwich press has sparked a revolution in the market. As more people seek out the perfect appliance for their culinary adventures, manufacturers have responded with innovative designs and features that cater to both casual cooks and professional chefs.

In the early days, the heavy-duty sandwich press was a simple tool with a straightforward mission: to toast bread to perfection. However, as the culinary landscape evolved, so too did the capabilities of these presses. Now, they come equipped with adjustable heat settings, non-stick surfaces, and even features that allow for pressing a variety of other foods, like grilled cheese, panini, and even open-faced sandwiches.

One of the key reasons for the rise of the heavy-duty sandwich press is its versatility. These presses are not just for sandwiches; they can be used to create a variety of toasted and grilled dishes, making them a valuable addition to any kitchen. Their ability to provide a consistent, even press ensures that every meal is cooked to perfection, with minimal effort on the part of the cook.

As the culinary world has become more adventurous, so too has the heavy-duty sandwich press. Designers have introduced a plethora of unique models, each with its own set of features. Some are designed with a sleek, modern aesthetic, while others have a more rustic, vintage charm. Regardless of the style, they all share one common goal: to make the art of sandwich-making accessible and enjoyable for everyone.

The rise of the heavy-duty sandwich press can also be attributed to the convenience it offers. No longer do you have to rely on the inconsistent heat of a stovetop griddle or the uneven toasting of a conventional toaster. With a sandwich press, you can achieve restaurant-quality results in the comfort of your own home. This convenience factor has been a significant draw for busy individuals and families who value efficiency and simplicity in their meal preparation.

Moreover, the heavy-duty sandwich press has become a favorite among health-conscious consumers. The ability to control the cooking temperature and cooking time ensures that the sandwich stays moist on the inside while achieving a perfect golden-brown crust on the outside. This feature makes it an ideal choice for those who want to enjoy their favorite sandwich without the guilt.

Behind the scenes, the manufacturers of these innovative sandwich presses are pushing the boundaries of design and technology. From the high-quality materials used to construct these presses to the precise engineering that ensures they perform flawlessly, there’s a lot of work that goes into creating a product that not only meets but exceeds expectations.

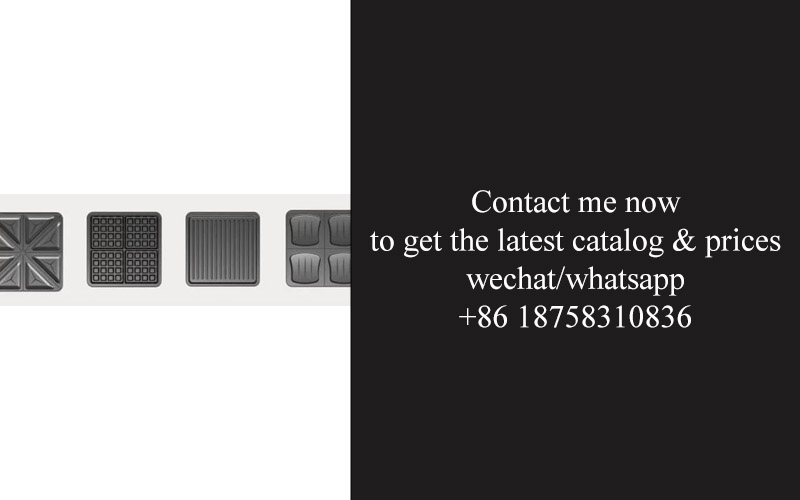

In recent years, there has been a growing trend towards customization in kitchen appliances. The heavy-duty sandwich press has embraced this trend by offering a range of interchangeable press plates, allowing users to create a variety of shapes and sizes for their sandwiches. This level of personalization has opened up new possibilities for creative cooks and has added an element of fun to the cooking process.

As the heavy-duty sandwich press continues to gain momentum, it’s clear that this kitchen gadget is here to stay. Its ability to transform the humble sandwich into a gourmet delight has made it an essential tool for anyone looking to elevate their at-home culinary experience. Whether you’re a sandwich aficionado or just someone who appreciates a good meal, the heavy-duty sandwich press is a game-changer that’s poised to remain a favorite for years to come.

Nestled within the bustling industrial landscape, the heavy-duty sandwich press factory stands as a beacon of innovation and efficiency. This isn’t just any factory; it’s a marvel of modern manufacturing, dedicated to crafting appliances that redefine the way we enjoy our meals, especially sandwiches.

The factory is a sprawling complex, with rows of state-of-the-art machinery working tirelessly to turn raw materials into durable and reliable sandwich presses. The architecture of the facility is both functional and inviting, with clean lines and ample natural light that reflects the brand’s commitment to transparency and quality.

Inside, the workflow is a symphony of precision. Skilled engineers and technicians oversee every step, ensuring that the heavy-duty sandwich presses are not only robust but also user-friendly. The factory floor is a testament to advanced engineering, where robotics and human expertise blend seamlessly.

At the heart of the operation is the research and development (R&D) department, a hub of creativity and problem-solving. This team is constantly experimenting with new materials, heat distribution technologies, and design elements to push the boundaries of what a sandwich press can do. They understand that in a world where food trends come and go, the only constant is innovation.

The manufacturing process itself is a blend of old-world craftsmanship and cutting-edge technology. Each piece of metal, plastic, and electronic component is carefully selected and processed to ensure durability. From the stainless steel frames to the non-stick surfaces, every detail is meticulously engineered to provide the ultimate sandwich-making experience.

Safety is paramount in this factory. Workers wear protective gear and are trained in the latest safety protocols. The factory is equipped with advanced fire suppression systems and regular health inspections to maintain a safe working environment. This attention to safety not only protects the workforce but also guarantees the highest quality products.

Quality control is another cornerstone of this heavy-duty sandwich press factory. Products are rigorously tested at various stages of the manufacturing process, from initial assembly to final inspection. These stringent tests ensure that each sandwich press that leaves the factory meets or exceeds the highest standards of performance and reliability.

The factory’s commitment to innovation extends beyond its walls. They collaborate with industry experts, chefs, and home cooks to understand their needs and preferences. This collaborative approach allows them to create products that not only look good but also deliver exceptional performance in the hands of users.

As the factory produces more heavy-duty sandwich presses, it also takes pride in its environmental responsibility. They have implemented energy-efficient systems and recycling programs to minimize their ecological footprint. This eco-conscious approach is not just a trend; it’s a core value that guides their operations.

In the heart of the factory, you’ll find a culture of continuous improvement. Employees are encouraged to share ideas and suggestions, contributing to a dynamic work environment that fosters innovation. This culture of innovation isn’t just about creating new products; it’s about enhancing the user experience and making everyday cooking a joy.

The heavy-duty sandwich press factory is more than just a place of production; it’s a community of passionate professionals united by a common goal. They understand that the sandwich press is more than just a kitchen appliance; it’s a tool that can inspire creativity, bring people together, and make everyday moments special.

In this factory, each heavy-duty sandwich press is not just a product; it’s a piece of art crafted with precision and love. It’s a testament to the dedication and ingenuity that goes into creating something that can bring joy to countless households around the world. And as the factory continues to innovate and grow, its legacy will undoubtedly live on in the satisfaction of every user who picks up one of their high-quality sandwich presses.

In the world of kitchen appliances, the heavy-duty sandwich press has emerged as a beacon of innovation and functionality. What sets this kitchen gadget apart from its counterparts? Let’s delve into the unique features and benefits that make a heavy-duty sandwich press truly standout.

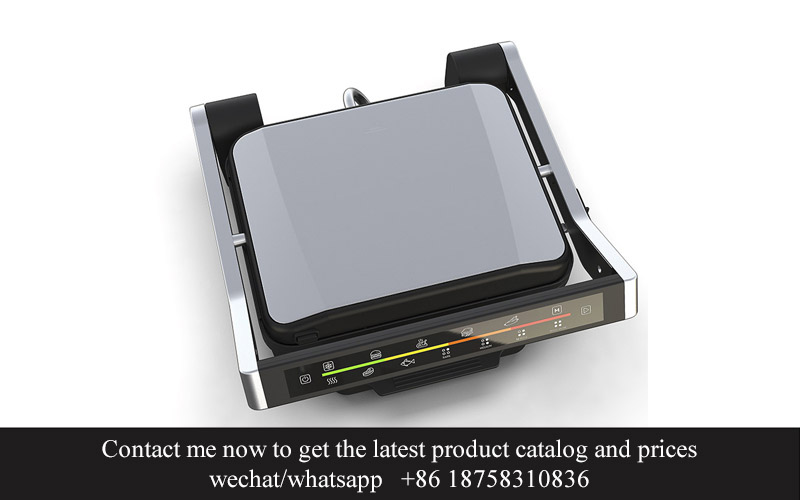

The robust build of a heavy-duty sandwich press is its cornerstone. Crafted from high-quality stainless steel, these presses are designed to withstand the rigors of everyday use. Their sturdy construction ensures that they can handle thick and hearty sandwiches without bending or warping, making them a reliable companion for years to come.

One of the most notable features of a heavy-duty sandwich press is its adjustable pressure system. This allows users to control the amount of pressure applied to the sandwich, resulting in a perfectly toasted bread with a golden crust and a melt-in-your-mouth texture. Whether you prefer a crispy or soft outer layer, the adjustable pressure setting caters to every taste.

Another standout feature is the non-stick surface. Made with a special coating, the plates of these sandwich presses prevent food from sticking, making cleanup a breeze. This feature is particularly appreciated by busy cooks who value time-saving and hassle-free kitchen experiences.

The size of the cooking surface is a crucial factor for many users. Heavy-duty sandwich presses often come with a larger cooking area, which means you can prepare sandwiches, paninis, and even mini pizzas in one go. This spacious design is perfect for families or individuals who love to cook and share their creations with others.

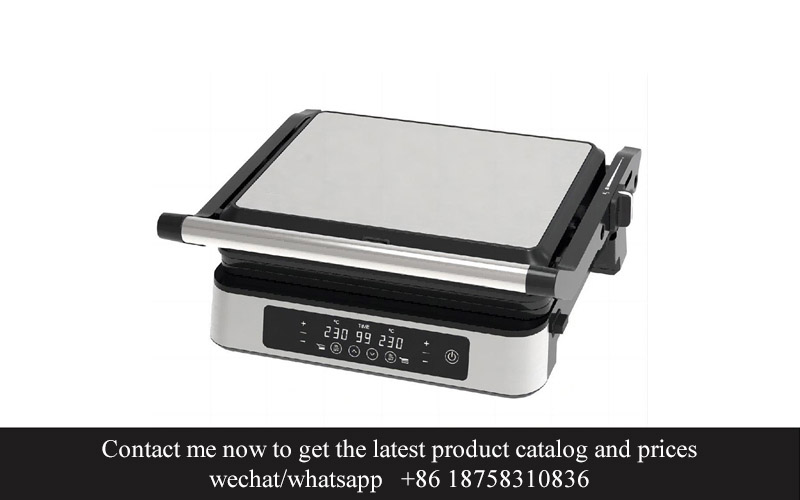

A unique feature that sets some heavy-duty sandwich presses apart is the presence of a temperature control mechanism. This allows users to precisely regulate the heat, ensuring that the sandwich is cooked to perfection. Whether you’re making a classic ham and cheese or a gourmet avocado and smoked salmon creation, the temperature control feature ensures that every ingredient is heated to the right degree.

The build quality of a heavy-duty sandwich press is not just about the materials used but also the attention to detail. Many models come with a locking mechanism that ensures the sandwich stays in place during cooking, preventing any shifting or sliding. This feature guarantees even toasting and a beautifully sealed sandwich.

Safety is another aspect that manufacturers of heavy-duty sandwich presses have not overlooked. These appliances often come with cool-touch handles and surfaces, so you can safely remove your sandwich without burning your hands. Additionally, some models have an automatic shut-off feature, which turns off the press once the cooking time is complete, adding an extra layer of safety.

In terms of convenience, heavy-duty sandwich presses are a dream come true. Most models are easy to store due to their compact design, and some even come with a carrying handle for portability. This means you can take your sandwich press on the go, whether you’re hosting a picnic or simply want to enjoy a freshly toasted sandwich at a friend’s house.

The versatility of a heavy-duty sandwich press is undeniable. It’s not just limited to sandwiches; you can use it to toast bagels, make grilled cheese, or even create gourmet burgers. The possibilities are endless, and the appliance itself is designed to handle these diverse cooking tasks with ease.

Finally, the durability of a heavy-duty sandwich press is a testament to its quality. The materials used, combined with the thoughtful design, mean that these presses are built to last. Even after years of use, they will continue to perform at a high level, providing consistent results every time.

In summary, the heavy-duty sandwich press stands out due to its robust build, adjustable pressure, non-stick surface, spacious cooking area, temperature control, safety features, convenience, versatility, and durability. These features make it an invaluable addition to any kitchen, promising to elevate the art of sandwich making to new heights.

The manufacturing process of a heavy duty sandwich press is a blend of precision engineering and culinary artistry. Here’s an in-depth look at the intricate steps involved:

Material Selection and Quality ControlThe journey begins with the selection of high-quality materials. Stainless steel is often the preferred choice for its durability and resistance to corrosion. The factory meticulously inspects each piece of metal, ensuring that only the finest components are used in the construction of the sandwich presses.

Design and PrototypingBefore the mass production starts, the factory’s design team works on creating detailed blueprints. These blueprints are then used to create prototypes, which are tested for functionality and ergonomic design. The goal is to create a sandwich press that not only performs well but also fits comfortably in the hands of the user.

Cutting and ShapingOnce the design is finalized, the steel sheets are cut to the required shapes using precision cutting machines. The factory employs advanced laser cutting technology to ensure clean, accurate cuts. These cut pieces are then shaped into the various parts of the sandwich press, including the top and bottom plates, handles, and hinges.

Welding and AssemblyThe shaped pieces are then carefully together. Skilled welders use TIG (Tungsten Inert Gas) welding to create strong, seamless joints. After welding, the parts are inspected for any defects. Once the major components are assembled, the internal mechanisms, such as springs and hinges, are added to ensure the press operates smoothly.

Painting and CoatingThe assembled sandwich press is then coated with a layer of protective paint. This not only enhances the appearance of the product but also provides a barrier against rust and corrosion. The paint is applied using an electrostatic spray system, which ensures even coverage and a glossy finish.

Quality Assurance and TestingBefore the sandwich press is deemed ready for market, it undergoes rigorous quality assurance checks. These include functional tests to ensure that the press can withstand the pressure required to make a perfect sandwich. The factory also tests for durability, checking that the press can be opened and closed thousands of times without any issues.

PackagingOnce the sandwich press passes all quality checks, it is packaged. The factory uses environmentally friendly materials for packaging, ensuring that the product is both safe for transport and sustainable. Each sandwich press is placed in a protective box, which includes all necessary information about the product, including usage instructions and warranty details.

DistributionAfter packaging, the sandwich presses are sent to distribution centers, where they are prepared for shipping to retailers and directly to consumers. The factory maintains a close relationship with logistics partners to ensure that the products reach their destinations promptly and in perfect condition.

Customer Feedback and Continuous ImprovementThe final step in the manufacturing process is gathering customer feedback. The factory values the input from users and uses it to make continuous improvements to the design and functionality of the sandwich press. This commitment to customer satisfaction is what sets the factory apart and ensures that each heavy duty sandwich press is a testament to quality and innovation.

In recent years, the demand for high-quality sandwich presses has surged, becoming a hot topic in the kitchen appliance market. This upward trend can be attributed to several key factors that have reshaped consumer preferences and buying behaviors.

The convenience of at-home sandwich-making has played a significant role in the popularity of sandwich presses. With busy lifestyles and the rise of fast-food alternatives, people are seeking ways to enjoy a delicious meal without leaving their homes. High-quality sandwich presses offer a solution, allowing for homemade, freshly toasted sandwiches with minimal effort.

Elevated culinary trends have also contributed to the growing demand for premium sandwich presses. From gourmet sandwiches to artisanal creations, home chefs are embracing the art of sandwich making. These enthusiasts are willing to invest in the right tools to perfect their craft, and a high-quality sandwich press is often seen as an essential part of their culinary arsenal.

Durability and reliability are critical factors that set high-quality sandwich presses apart from their cheaper counterparts. These appliances are designed to withstand daily use and the rigors of repeated heating. With sturdy construction and long-lasting components, they become a valuable asset in the kitchen for years to come.

The rise of social media and online influencers has had a profound impact on kitchen appliance trends. Chefs and home cooks often showcase their creations on platforms like Instagram and TikTok, and high-quality sandwich presses are frequently featured in these posts. The visual appeal and the promise of achieving impressive results at home have sparked a desire among consumers to own these sought-after gadgets.

Customization options have become increasingly popular, and high-quality sandwich presses often come with a variety of features that cater to different preferences. Whether it’s adjustable pressure settings, non-stick surfaces, or multiple color options, these presses allow users to tailor their sandwich-making experience to their taste.

The market for high-quality sandwich presses is not limited to domestic consumers; there is also a growing demand from commercial kitchens, including cafes, restaurants, and catering services. These establishments require appliances that can handle heavy use and produce consistent results. High-quality sandwich presses are designed to meet these demands, offering a professional-grade solution for commercial sandwich preparation.

Energy efficiency has become a significant consideration for consumers and businesses alike. High-quality sandwich presses are often designed with energy-saving technologies, reducing electricity consumption and contributing to a more sustainable kitchen environment.

Lastly, the global health and wellness movement has spurred interest in homemade meals that are perceived to be healthier than processed foods. High-quality sandwich presses make it easier for individuals to control the ingredients in their sandwiches, fostering a sense of security and satisfaction with their dining choices.

In conclusion, the growing demand for high-quality sandwich presses is a multifaceted trend that reflects changing consumer values and expectations. From convenience and culinary aspirations to durability and sustainability, these appliances are meeting a wide range of needs, solidifying their place as a key player in the kitchen appliance market.

In the heart of modern sandwich-making, factories are bustling with innovation, pushing the boundaries of what a sandwich press can do. These aren’t just any presses; they’re heavy-duty machines designed to transform humble bread into culinary masterpieces. Let’s take a closer look at the innovative designs that are shaping the future of sandwich making.

The sleek, ergonomic handles on these presses are not just stylish; they’re a testament to user comfort and control. Crafted with a focus on grip and ease of use, they ensure that even the most intricate sandwiches can be pressed with precision. The handles are often heat-resistant, allowing for safe handling even when the press is hot after use.

The non-stick surfaces of these heavy-duty sandwich presses are a game-changer. No more worrying about the bread sticking to the plates, which means fewer cleanups and more time to enjoy the delicious results. The smooth, easy-to-clean surfaces are a nod to the busy home chef who values efficiency.

The adjustable pressure settings are a feature that sets these presses apart. From soft, melt-in-your-mouth sandwiches to those with a perfectly golden crust, the ability to control the pressure means you can tailor each sandwich to your taste. This versatility is a hit with both casual cooks and culinary enthusiasts alike.

The inclusion of removable plates is not just convenient; it’s a health and safety feature. These plates can be easily removed for cleaning, reducing the risk of foodborne illnesses and making maintenance a breeze. The design often includes a secure locking mechanism to ensure the plates stay in place during the pressing process.

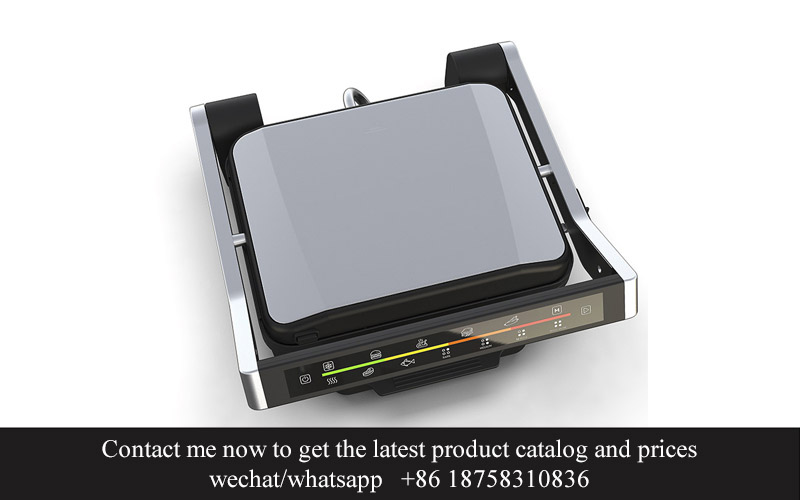

The integration of LED temperature indicators is a nod to modern technology. These presses come with digital displays that show the exact temperature, ensuring that the sandwich is cooked to perfection every time. No more guessing or overcooking; just a perfectly toasted sandwich, every time.

Some models even feature a built-in timer, which is a godsend for those who want to multitask in the kitchen. The timer alerts you when the sandwich is ready, so you can focus on other dishes or simply enjoy a moment of relaxation.

The materials used in these heavy-duty sandwich presses are top-notch. High-quality stainless steel is the norm, not only for its durability but also for its ability to withstand high temperatures without warping or bending. This means your press will last for years, even with frequent use.

The design of these presses often includes a drip tray to catch any excess oil or moisture, keeping your kitchen counters clean and your cooking area organized. This thoughtful addition is a small detail that makes a big difference in the overall cooking experience.

In terms of aesthetics, these sandwich presses are as appealing as they are functional. They come in a variety of colors and finishes, from classic black to sleek silver, ensuring that they complement any kitchen decor. The design is not just about looks; it’s about creating a cohesive and visually appealing kitchen environment.

The innovation doesn’t stop at the physical design. Many presses now come with features like adjustable browning controls, allowing you to customize the color of your sandwich’s crust. This level of control is something that was once only available in professional kitchens, but now it’s accessible to home cooks everywhere.

The compact size of these presses is another feature that stands out. Despite their heavy-duty build, they are designed to be space-saving, making them perfect for small kitchens or those who prefer a minimalist look. This compact design doesn’t compromise on performance; it simply makes the most of the available space.

In the world of sandwich making, these innovative designs are a glimpse into the future. They combine the best of traditional sandwich-making techniques with modern technology and design, creating a product that is both practical and enjoyable to use. As the demand for high-quality sandwich presses continues to grow, it’s clear that these innovations are not just a trend but a new standard in the kitchen.

In the world of culinary innovation, the heavy-duty sandwich press has emerged as a tool that’s not just a kitchen gadget but a cornerstone of modern sandwich-making. The role of technology in its production has been pivotal, driving both efficiency and quality. Let’s delve into how technology has reshaped the manufacturing process of these robust sandwich presses.

Precision engineering has become the backbone of heavy-duty sandwich press production. Modern factories employ computer-aided design (CAD) software to create intricate and precise molds for the presses. These molds are crafted with intricate details that ensure uniform pressure distribution, which is crucial for achieving that perfect, golden-brown crust on every sandwich.

Automated assembly lines have revolutionized the production process. Robots and specialized machinery are used to assemble components with unparalleled accuracy. This not only speeds up the production time but also reduces the margin for human error. The precision of these machines ensures that every sandwich press that rolls off the line meets the stringent quality standards set by the factory.

The integration of smart sensors and monitoring systems has introduced a new level of control into the manufacturing process. These sensors track the temperature, pressure, and other critical parameters during the heat-treating and finishing stages. By ensuring that every press is exposed to the right amount of heat and pressure, the technology guarantees consistent performance and longevity.

In the realm of materials, technological advancements have led to the use of high-quality, durable materials. The heavy-duty sandwich presses are often made from stainless steel, which is not only resistant to rust but also maintains its shape and integrity over time. The development of advanced heat-resistant coatings has also extended the life of the presses, protecting them from the rigors of constant use.

Energy efficiency is another area where technology has made a significant impact. Modern heavy-duty sandwich press factories are equipped with energy-saving technologies that reduce power consumption. LED lighting, for instance, provides ample illumination while using a fraction of the energy compared to traditional bulbs. This not only cuts down on operational costs but also aligns with global efforts to reduce carbon footprints.

The integration of IoT (Internet of Things) into the production process has allowed for real-time data collection and analysis. This data-driven approach enables manufacturers to identify trends, predict maintenance needs, and make informed decisions that can improve the overall efficiency of the factory. For example, predictive maintenance can be scheduled based on the usage patterns of the machinery, reducing downtime and extending the lifespan of the equipment.

Safety is paramount in any manufacturing environment, and technology has played a crucial role in enhancing it. The use of advanced safety systems ensures that workers are protected from potential hazards. These systems include emergency stop mechanisms, machine guarding, and comprehensive training programs that keep employees informed about the latest safety protocols.

The design of heavy-duty sandwich presses has also been influenced by consumer feedback and market trends. The factory floor is a hub of creativity, where designers use technology to create presses that are not only functional but also aesthetically pleasing. Features like non-slip surfaces, easy-to-clean designs, and ergonomic handles are all the result of technology-driven innovation.

As the world becomes more health-conscious, the heavy-duty sandwich press has adapted to cater to these demands. Technology has enabled the development of presses that can cook sandwiches with minimal oil, making them healthier options. Additionally, the ability to adjust cooking temperatures and times allows for customization, ensuring that each sandwich meets individual preferences.

In conclusion, technology has become an indispensable part of heavy-duty sandwich press production. From the precision engineering of molds to the automation of assembly lines and the integration of IoT, every aspect of the manufacturing process is enhanced by technology. This not only ensures that the final product is of the highest quality but also paves the way for continuous improvement and innovation in the future.

In the realm of heavy-duty sandwich press manufacturing, sustainability and eco-friendly practices are not just buzzwords; they are integral to the operational ethos of many factories. Here’s a closer look at how these principles are woven into the very fabric of production.

The factory floor is a bustling hub of activity, where every piece of equipment is designed with a mindful approach to the environment. From the moment raw materials arrive, the focus is on minimizing waste and maximizing efficiency.

Recycling and waste reduction are at the forefront of these practices. Metal shavings and plastic scraps that would typically end up in landfills are meticulously collected and sent to recycling facilities. This not only helps in reducing the environmental impact but also creates a secondary income stream for the factory.

Energy conservation is another critical aspect. Factories invest in energy-efficient lighting and machinery that consume less power while maintaining high productivity. Solar panels and wind turbines are often installed to harness renewable energy sources, further reducing the carbon footprint.

The use of sustainable materials is not limited to the end product; it extends to the manufacturing process itself. Biodegradable plastics and recycled metals are favored for their environmental benefits. These materials are not only better for the planet but also contribute to the longevity and durability of the sandwich presses.

Water usage is carefully managed to prevent wastage. Advanced filtration systems are employed to recycle and reuse water, ensuring that every drop is utilized efficiently. This not only conserves a precious resource but also reduces the factory’s water bill.

The health and safety of workers are also closely tied to sustainability efforts. Factories often invest in air filtration systems to maintain clean working environments, which also helps in reducing the emission of pollutants into the atmosphere.

Innovation in manufacturing processes is key to sustainability. Factories are constantly seeking out new ways to reduce their impact on the environment. This includes the development of low-energy manufacturing techniques and the integration of automation to minimize the need for manual labor, which in turn reduces energy consumption.

Training programs are in place to educate employees about sustainable practices. Workers are encouraged to adopt eco-friendly habits both in the workplace and in their personal lives. This creates a culture of environmental responsibility throughout the factory.

The packaging of the finished heavy-duty sandwich presses is also a point of focus. Biodegradable materials are used, and packaging designs are optimized to minimize material usage without compromising product protection.

As the demand for eco-friendly products grows, heavy-duty sandwich press factories are responding by certifying their processes. Achieving certifications like ISO 14001 for environmental management systems is a testament to their commitment to sustainability.

The end result is a product that not only performs well but also carries the promise of a better future for the planet. Customers who choose these sandwich presses are not just getting a high-quality appliance; they are also making a choice that aligns with their values of sustainability and environmental stewardship.

In conclusion, the integration of sustainability and eco-friendly practices in heavy-duty sandwich press factories is a multifaceted endeavor that touches every aspect of the production process. From the materials used to the energy consumed, every decision is made with the environment in mind, ensuring that the future of sandwich making is both delicious and responsible.

In the bustling world of kitchen gadgets, heavy duty sandwich presses have gained a cult following, and it’s not hard to see why. These sturdy appliances are not just for the casual cook; they’re for those who demand perfection in every bite. Here are some genuine testimonials from customers who’ve had their hearts and taste buds captivated by these powerful sandwich makers.

“I’ve tried my fair share of sandwich presses, but nothing compares to the heavy-duty model I got my hands on. The even pressure and non-stick surface have made every sandwich a delight to eat. No more soggy bread or undercooked fillings!”

“I was skeptical at first, but the durability of this sandwich press has won me over. It’s been through countless meals, and it still looks and works like new. I love how it adds that perfect crunch to my favorite gourmet sandwiches.”

“My husband and I are food enthusiasts, and we’ve tried making our own paninis at home. The heavy duty press has been a game-changer. The consistent heat and even pressure have turned our homemade sandwiches into restaurant-quality fare.”

“I’ve had my sandwich press for over a year now, and it’s still going strong. The fact that it’s made with high-quality materials and built to last is impressive. I’ve recommended it to all my friends who are sandwich lovers.”

“The build quality of this heavy duty sandwich press is top-notch. It feels solid in your hands, and the controls are intuitive. I appreciate the ability to adjust the pressure, which means I can make everything from classic ham and cheese to exotic fusion sandwiches with ease.”

“One of the best features of this sandwich press is the variety of patterns it leaves on the bread. It adds a nice texture and visual appeal to each sandwich. My kids love it, and it’s become a fun family activity to create new sandwich designs.”

“I travel often for work, and having this sandwich press in my bag has been a game-changer. It’s small enough to fit in my luggage, and it’s made it possible for me to enjoy a good, warm sandwich even when I’m on the go.”

“I bought this sandwich press as a gift for my sister, who’s a food blogger. She’s been using it to create visually stunning content for her followers. The quality of her posts has improved dramatically since she got it, and she can’t stop raving about how much it’s enhanced her cooking.”

“The heavy duty sandwich press has become a staple in my kitchen. Whether I’m making a quick lunch or entertaining guests, it always delivers. The ease of use and the delicious results make it a must-have for any sandwich aficionado.”

“The customer service I received with this sandwich press was exceptional. The team was helpful, and they made sure I was satisfied with my purchase. It’s nice to see a company that stands behind its products.”

In a world where kitchen appliances often come and go, the heavy duty sandwich press has stood the test of time. These testimonials from real people speak volumes about the joy and satisfaction these appliances bring to the sandwich-making experience. From home chefs to food bloggers, it’s clear that the heavy duty sandwich press has captured the hearts and stomachs of many.

Navigating the market for heavy-duty sandwich presses can be a daunting task, especially with the myriad of options available. Here are some key pointers to help you find the best heavy-duty sandwich presses for your needs.

Quality over Quantity: When it comes to heavy-duty sandwich presses, the focus should be on quality. Look for brands that prioritize durability and longevity. A sturdy build ensures that your sandwich press will withstand the rigors of daily use in a commercial setting.

Material Matters: The material used in the construction of a sandwich press can significantly impact its performance and lifespan. Opt for presses made from high-quality stainless steel, which is not only durable but also resistant to rust and corrosion. Aluminum is another popular choice for its even heat distribution.

Even Heat Distribution: A crucial feature for any sandwich press is even heat distribution. This ensures that your sandwiches are cooked thoroughly and consistently. Look for presses with non-stick surfaces or those that come with adjustable heat settings to achieve the perfect level of crispiness on the outside and a warm, melty inside.

Size and Capacity: Consider the size and capacity of the sandwich press that you need. For commercial use, you’ll want a press that can handle multiple sandwiches at once. Some models are designed for individual servings, while others can accommodate larger portions or even sliders. Make sure the size of the press aligns with your operational requirements.

Safety Features: Safety should always be a top priority. Look for sandwich presses with features like cool-to-the-touch handles, automatic shut-off functions, and overheat protection. These features not only ensure the safety of your customers but also protect your equipment from damage.

Ease of Cleaning: A heavy-duty sandwich press should be easy to clean to maintain hygiene and efficiency. Non-stick surfaces and removable parts can make the cleaning process quicker and more straightforward. Some models even come with self-cleaning functions or are dishwasher-safe.

Brand Reputation: Research the reputation of the brands you’re considering. Look for reviews and testimonials from other businesses that use their products. A brand with a strong track record of customer satisfaction and reliable customer service is often a good choice.

Budget Considerations: Determine your budget for the sandwich press and look for models that offer the best value for money. While it’s tempting to go for the cheapest option, investing in a higher-quality press can save you money in the long run by reducing the need for frequent replacements.

Warranty and Support: Check the warranty offered by the manufacturer. A longer warranty period can provide peace of mind, knowing that the manufacturer stands behind their product. Additionally, consider the level of customer support provided, including how quickly they can address any issues or repairs.

Special Features: Depending on your specific needs, certain special features might be beneficial. For example, some sandwich presses come with adjustable plates for different sandwich sizes, or even built-in timers to ensure your sandwiches are cooked to perfection.

Remember, the best heavy-duty sandwich press for you will depend on your specific requirements, whether that’s the size of your business, the type of sandwiches you serve, or your budget. Take the time to compare different models and read reviews from other users to make an informed decision. With the right sandwich press, you’ll be able to serve delicious, perfectly cooked sandwiches that keep your customers coming back for more.