Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the air fryer market continues to boom, understanding the intricacies of selecting the perfect turnkey OEM partner is crucial for companies looking to stay ahead in this competitive landscape. With a plethora of options and evolving consumer demands, finding a reliable and innovative partner is not just beneficial—it’s essential for long-term success. This article delves into the factors to consider when choosing the right turnkey UL certified air fryer OEM partner, ensuring that your product not only meets but exceeds market expectations.

The air fryer market has experienced a remarkable surge in popularity over recent years, transforming the way consumers approach cooking and healthy eating. Once a niche product, these compact kitchen appliances have now become a staple in many households, thanks to their ability to offer deliciously crispy fried foods with significantly less oil than traditional deep-frying methods.

This shift in consumer behavior can be attributed to several factors. Firstly, there’s a growing awareness of health and wellness, with more people seeking out ways to reduce their fat and calorie intake without sacrificing flavor. Air fryers provide a guilt-free alternative that still satisfies the craving for fried foods, making them an appealing choice for health-conscious consumers.

Secondly, the convenience factor cannot be overlooked. Air fryers are compact and easy to use, requiring minimal cleanup compared to deep fryers. They also offer a variety of cooking modes, from crispy fries to juicy chicken wings, which cater to a wide range of culinary preferences.

The technology behind air fryers has also seen significant advancements. Modern models are equipped with precise temperature controls and timers, ensuring that food is cooked to perfection every time. These features have helped to elevate the air fryer from a simple kitchen gadget to a versatile cooking tool that can be used for a variety of recipes.

Another contributing factor to the air fryer market’s rise is the influence of social media and cooking blogs. Chefs and influencers have been showcasing their air fryer creations, inspiring home cooks to experiment with their own recipes. The hashtag #airfryerrecipes has become a trending topic, with millions of posts featuring creative and appetizing dishes cooked in an air fryer.

As the market has expanded, so too has the competition. Major appliance brands have jumped on the bandwagon, releasing their own lines of air fryers with unique features and designs. This has led to a wider selection of products for consumers to choose from, each offering something different to appeal to various needs and budgets.

In response to the demand for health and convenience, manufacturers have been quick to innovate. Some air fryers now come with additional functions, such as dehydrating, roasting, and even baking. These multi-functional units have become increasingly popular, as they offer a one-stop solution for a variety of cooking tasks.

The market has also seen the emergence of eco-friendly air fryers, which are designed with sustainability in mind. These models often use less energy and are made from recyclable materials, appealing to environmentally conscious consumers who want to reduce their carbon footprint.

From a commercial perspective, the air fryer market has presented a golden opportunity for Original Equipment Manufacturers (OEMs). As the demand for air fryers continues to grow, OEMs are in a prime position to supply the market with customized and high-quality air fryer units. This has led to a surge in OEM partnerships, with manufacturers seeking to leverage the expertise and efficiency of these specialized companies.

Customization is key in the air fryer market. OEMs can work closely with brands to develop products that align with their specific design and functionality requirements. This not only allows for a unique product offering but also ensures that the end consumer receives a high-quality, reliable appliance.

The rise of the air fryer market has also been fueled by the need for compliance with safety standards. This is where UL certification comes into play. OEMs that offer turnkey solutions for air fryers with UL certification are able to provide peace of mind to consumers and retailers alike, knowing that the products meet stringent safety and quality standards.

In conclusion, the air fryer market’s rise is a testament to the power of innovation, consumer demand, and the importance of health and convenience. As the market continues to evolve, it’s clear that air fryers are here to stay, and OEMs are playing a crucial role in shaping the future of this dynamic industry.

In today’s fast-paced business environment, the demand for efficiency and cost-effectiveness is at an all-time high. This is where turnkey solutions come into play, offering a comprehensive package that simplifies operations and reduces the complexities of production for manufacturers and businesses alike.

Turnkey solutions are essentially complete packages that include everything needed for a project to be operational from the outset. This means that clients don’t have to worry about sourcing individual components, managing logistics, or dealing with the technical intricacies of assembly. The turnkey approach ensures that the client can focus on their core competencies while leaving the execution to the experts.

One of the key benefits of turnkey solutions is the reduction in time to market. When a company decides to develop a new product or enter a new market, every minute counts. Turnkey solutions streamline the process by providing a ready-to-use product or service, which can significantly shorten the time from concept to delivery. This is particularly crucial in industries where being first to market can mean capturing a larger share of the market or securing a competitive edge.

Cost management is another significant advantage of turnkey solutions. By handling all aspects of the project, including design, engineering, manufacturing, and installation, turnkey providers can often negotiate better prices with suppliers and manufacturers. This means that clients can enjoy savings on materials, labor, and overhead costs, all while benefiting from the provider’s expertise in cost optimization.

Quality control is a non-negotiable aspect of any successful project, and turnkey solutions excel in this area. Since turnkey providers are responsible for the entire process, they have a vested interest in ensuring that the final product meets the highest standards. This often involves rigorous testing and quality assurance protocols that might be difficult for a client to implement on their own, especially if they are not experts in the field.

Customization is often a challenge when working with multiple vendors or suppliers. Turnkey solutions, however, offer the flexibility to tailor the product or service to meet specific client requirements. Whether it’s modifying a design, incorporating new features, or adapting to different market conditions, turnkey providers can accommodate these needs without disrupting the overall project timeline.

Another critical aspect of turnkey solutions is the reduction in administrative overhead. Managing multiple suppliers and vendors can be a complex and time-consuming task. With a turnkey provider, the client can eliminate the need for a dedicated project management team, allowing them to allocate resources more efficiently and focus on strategic initiatives.

Innovation is also fostered through turnkey solutions. By partnering with a provider that has a deep understanding of the industry and access to the latest technologies, clients can tap into a wealth of ideas and solutions that they might not have considered. This can lead to more innovative products or services and can position the client as an industry leader.

Moreover, turnkey solutions often come with a level of risk mitigation that is hard to achieve independently. Turnkey providers have experience in dealing with the unforeseen challenges that can arise during a project’s lifecycle. They have contingency plans in place and can quickly address issues that could otherwise lead to project delays or cost overruns.

For businesses looking to expand or enter new markets, turnkey solutions can be a game-changer. They provide a fast-track to market entry by offering a complete solution that can be up and running quickly. This is particularly beneficial in regions where infrastructure and resources may be limited, as turnkey providers can leverage their global network to ensure a seamless implementation.

In conclusion, turnkey solutions are a powerful tool for businesses seeking efficiency, cost savings, and quality assurance. By providing a comprehensive, end-to-end service, turnkey providers can help clients navigate the complexities of production and market entry, allowing them to focus on what they do best. Whether it’s a manufacturing project, a service rollout, or a new product launch, the turnkey approach can be the key to success in today’s competitive landscape.

In today’s fast-paced and highly competitive market, ensuring that products meet stringent safety and quality standards is paramount. This is where UL certification comes into play, serving as a beacon of trust for consumers and businesses alike. Understanding the intricacies of UL certification is crucial for anyone looking to navigate the product landscape safely and effectively.

The UL Mark: A Symbol of SafetyThe UL mark, also known as the UL Certification Mark, is a globally recognized symbol that stands for Underwriters Laboratories, an independent product safety certification organization. When a product bears the UL mark, it signifies that it has been tested and evaluated to meet or exceed recognized safety standards.

The Rigorous Testing ProcessThe process of obtaining a UL certification is thorough and comprehensive. Products are subjected to a series of tests that are designed to simulate real-world conditions and potential hazards. These tests can range from electrical safety to material durability, flame resistance, and even ergonomic considerations.

Safety Standards and ComplianceUL certification is based on a vast array of safety standards that are developed by UL’s technical experts. These standards are not only established for new products but also for existing products undergoing modifications. Compliance with these standards is not just about meeting a minimum requirement; it’s about ensuring that the product is safe for its intended use.

The Impact on Consumer TrustConsumers are increasingly cautious about the safety of the products they purchase. The UL mark can significantly influence purchasing decisions, as it provides a level of assurance that the product has been evaluated by a reputable third-party organization. This trust is especially important in industries where safety is a top priority, such as electronics, appliances, and building materials.

Global Reach and RecognitionUL certification is not limited to a single region; it is recognized worldwide. This global acceptance means that products certified by UL can easily enter international markets, reducing the need for additional testing and certification in each country. For manufacturers, this can streamline the export process and open up new opportunities.

The Benefits for BusinessesFor businesses, UL certification offers several advantages. It can serve as a competitive differentiator, as it demonstrates a commitment to quality and safety. It can also enhance brand reputation and customer loyalty. Moreover, it can help mitigate the risk of product liability claims, as certified products are less likely to cause harm to users.

The Evolution of UL StandardsUL standards are not static; they evolve with technological advancements and new safety challenges. The organization continuously updates its standards to reflect the latest research and industry practices. This ensures that certified products remain at the forefront of safety and innovation.

The Role of Certification BodiesWhile UL is one of the most well-known certification bodies, there are others that play a similar role. Understanding the differences between various certification bodies and the specific standards they follow is important for manufacturers looking to expand their reach or enter new markets.

Certification vs. TestingIt’s important to note that certification is not the same as testing. While testing is a part of the certification process, certification involves a comprehensive assessment that includes testing, inspection, and auditing. This holistic approach ensures that the entire product lifecycle is managed with safety in mind.

The Future of UL CertificationLooking ahead, the role of UL certification is likely to expand as technology continues to advance. With the rise of smart devices and the Internet of Things (IoT), new safety challenges will emerge. UL is already working on developing standards for these emerging technologies, ensuring that they are safe for consumers and businesses.

In conclusion, understanding UL certification is key to navigating the complexities of product safety and compliance. It’s not just about meeting standards; it’s about building trust, enhancing brand reputation, and ensuring that products are safe for users around the world.

In the bustling air fryer industry, Original Equipment Manufacturers (OEMs) play a pivotal role, acting as the architects behind the scenes. They’re the unsung heroes that bring innovative kitchen appliances to life, ensuring that consumers worldwide enjoy not just products, but experiences.

OEMs are the masterminds behind the design and production of air fryers. They take raw materials and transform them into sleek, efficient, and user-friendly appliances. This process involves meticulous engineering, rigorous testing, and a deep understanding of consumer needs. By focusing on these elements, OEMs ensure that each air fryer they produce is not just a gadget, but a valuable addition to any kitchen.

The OEM’s expertise lies in understanding market trends and consumer preferences. They stay ahead of the curve, incorporating the latest technologies and features into their air fryer designs. This forward-thinking approach means that OEMs can cater to a diverse range of customers, from health-conscious individuals seeking healthier cooking alternatives to families looking for easy, convenient meal prep solutions.

Customization is another key strength of OEMs. They work closely with brands to create air fryers that align with their specific product lines and brand identity. Whether it’s a sleek, modern design or a rugged, durable build, OEMs can tailor their products to meet the unique requirements of each client. This level of personalization is what sets OEMs apart and allows them to offer truly unique products to the market.

Quality control is non-negotiable in the air fryer industry, and OEMs take this aspect seriously. They implement strict quality assurance protocols to ensure that every air fryer that leaves their factory meets the highest standards. This includes everything from component sourcing to final assembly, and even post-production testing. By maintaining such high standards, OEMs help to build trust with consumers and establish their brand as a leader in the air fryer market.

Innovation is the lifeblood of the air fryer industry, and OEMs are at the forefront of this movement. They are constantly seeking out new ways to improve existing products and develop entirely new ones. This could involve anything from integrating smart technology for remote monitoring to creating air fryers that use less energy and produce fewer emissions. By fostering innovation, OEMs are not only driving the industry forward but also setting new benchmarks for what’s possible in kitchen appliances.

Another crucial role of OEMs is in the supply chain. They manage the entire production process, from sourcing raw materials to distribution. This comprehensive approach ensures that the right components are used, the manufacturing process is efficient, and the final product is delivered to the market in a timely manner. By handling the supply chain, OEMs can also offer competitive pricing, which is a significant draw for brands looking to offer affordable air fryers to their customers.

Collaboration is a cornerstone of the OEM’s role in the air fryer industry. They work closely with brands to understand their vision and bring it to life. This collaboration often results in co-branded products that offer something special to the market. By combining their technical expertise with the brand’s market knowledge, OEMs can create products that resonate with consumers and stand out in a crowded marketplace.

Finally, OEMs are instrumental in the global expansion of the air fryer industry. They are capable of scaling production to meet international demand, and they understand the nuances of different markets. Whether it’s adapting products to comply with local regulations or marketing strategies that resonate with specific cultures, OEMs help brands navigate the complexities of international trade.

In summary, OEMs are the backbone of the air fryer industry. They are the innovators, the customizers, the quality controllers, the supply chain managers, the collaborators, and the global strategists. Without them, the air fryer revolution would not be possible, and the kitchen appliances we love today might look very different.

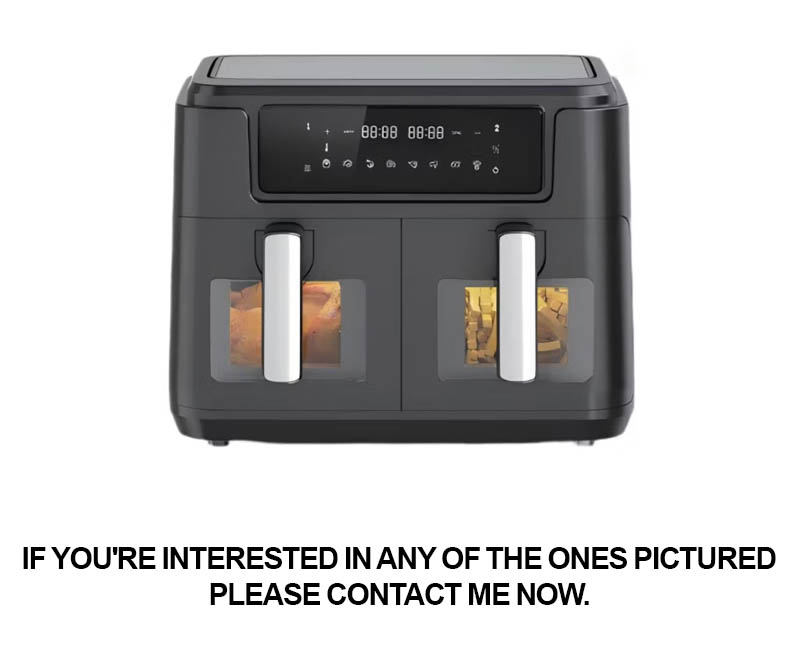

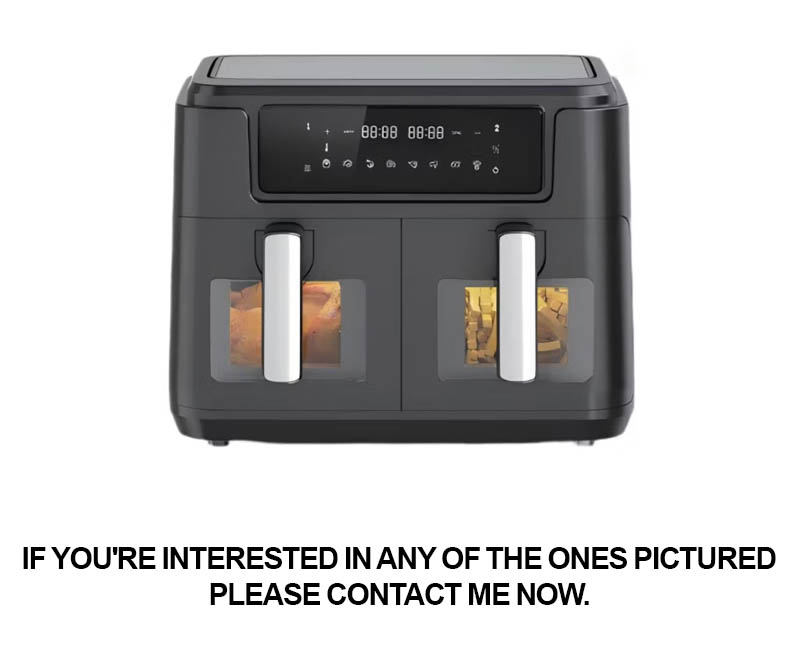

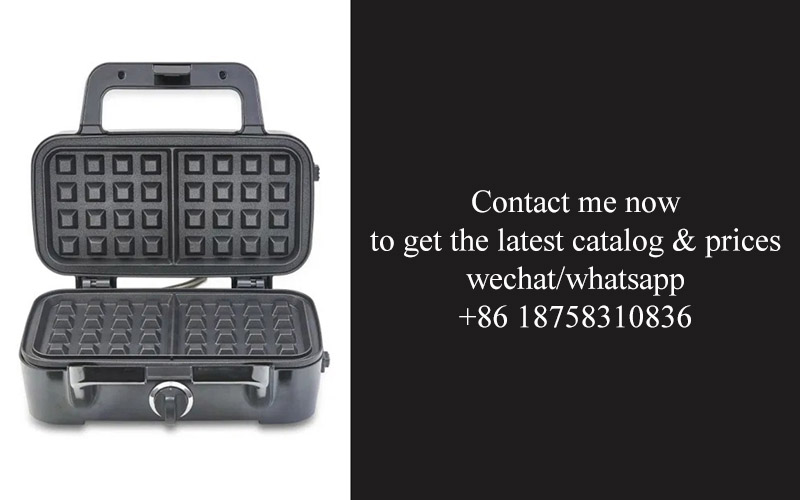

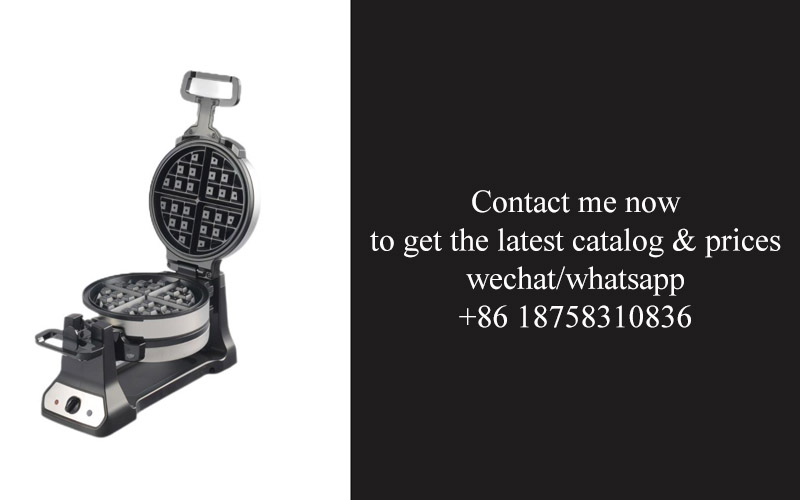

The air fryer market has seen a surge in innovation, transforming the way we think about healthy cooking. These appliances, once a niche product, have now become a staple in many kitchens. Here’s a look at some of the latest and most exciting innovations in air fryer design:

Smart Technology Integration – Modern air fryers are not just cooking appliances; they are smart devices. With features like Wi-Fi connectivity, they can be controlled via smartphone apps. Users can set timers, monitor cooking progress, and even receive notifications when the food is ready, all from the comfort of their smartphone.

Programmable Settings and Presets – To cater to a wide range of cooking preferences, new air fryers come with programmable settings and presets. These allow users to select from a variety of recipes, whether it’s crispy fries, golden chicken, or tender vegetables. The appliance then adjusts the temperature and cooking time accordingly.

Advanced Heat Distribution – One of the key challenges in air frying has been even heat distribution. New designs address this with advanced heat circulation systems. These include convection fans and multi-layered cooking chambers that ensure every piece of food gets the same level of cooking, resulting in more consistent and delicious results.

Eco-Friendly and Energy-Efficient – With growing environmental concerns, manufacturers are focusing on making air fryers more energy-efficient. New models often feature eco modes that reduce power consumption without compromising on cooking performance. This not only saves money on energy bills but also contributes to a greener planet.

Improved Interior Design – The interior of an air fryer is just as important as its exterior. Recent innovations include non-stick coatings that are more durable and easier to clean. Some models also have removable baskets and trays, making it even simpler to wash and store the appliance.

Portability and Compactness – As air fryers become more popular, there’s a growing demand for portability. New designs are lighter and more compact, making them perfect for small kitchens or for those who like to cook on the go. Some models are even designed to fold flat for storage, saving space when not in use.

Healthier Cooking Options – Health-conscious consumers are always looking for ways to reduce oil in their cooking. Some air fryer innovations include a “healthy oil” mode that uses less oil than traditional air frying methods, making the food healthier while still achieving that crispy texture.

Enhanced Safety Features – Safety is a top priority in kitchen appliances, and air fryers are no exception. New designs include features like automatic shut-off when the unit is left unattended, cool-touch exteriors to prevent burns, and child safety locks to prevent accidents.

Cooking at Different Levels – To cater to a variety of recipes, some air fryers now come with adjustable racks or levels, allowing users to cook multiple items at different temperatures simultaneously. This is particularly useful for batch cooking or preparing dishes with varying cooking times.

Customizable Exterior Finishes – Finally, the aesthetic appeal of an air fryer is also being taken into consideration. Some models now offer customizable exterior finishes, allowing consumers to match their appliances to their kitchen decor or personal style.

These innovations in air fryer design reflect the industry’s commitment to meeting the evolving needs and preferences of consumers. As technology continues to advance, we can expect even more creative and efficient solutions that make air frying not just a healthier cooking option, but a more convenient and enjoyable one as well.

Navigating the complexities of the air fryer market can be daunting, especially for Original Equipment Manufacturers (OEMs). But with turnkey UL certified air fryer OEM services, these complexities are simplified, offering a range of benefits that can significantly impact a brand’s success. Let’s delve into the advantages that come with these services.

Efficient Production ProcessThe turnkey approach means that OEMs can hand over the entire manufacturing process to a single source. This eliminates the need for OEMs to manage multiple suppliers, ensuring a streamlined and efficient production process. By having all components and assembly handled under one roof, OEMs save time and reduce the risk of production delays.

Quality Control AssuranceOne of the most critical aspects of any product is its quality. Turnkey UL certified air fryer OEM services guarantee that each unit meets the highest safety standards. With rigorous quality control measures in place, OEMs can be confident that their products are not only safe but also reliable, which is crucial for building trust with consumers.

Customization and BrandingOEMs often seek to differentiate their products in a crowded market. Turnkey services allow for customization, from the design of the air fryer’s exterior to the inclusion of specific features. This not only helps in branding but also ensures that the product aligns with the OEM’s brand identity and the expectations of their target market.

Cost ReductionBy utilizing turnkey services, OEMs can benefit from economies of scale. Bulk purchasing of components, combined with optimized production techniques, can lead to significant cost savings. Additionally, the elimination of middlemen and the need for separate quality control processes can further reduce overhead costs.

Time to MarketThe development and launch of a new product can be a lengthy process. However, with turnkey services, OEMs can significantly reduce the time to market. The integrated approach means that every step, from design to manufacturing, is managed efficiently, ensuring that the product can reach consumers faster.

Regulatory ComplianceNavigating the various regulations and standards in different markets can be challenging. Turnkey UL certified air fryer OEM services take care of all regulatory compliance, ensuring that the product meets not just UL standards but also any local regulations. This reduces the risk of product recalls and legal issues for the OEM.

Innovation and Technology IntegrationThe air fryer industry is continuously evolving with new technologies and features. Turnkey services often include the latest innovations, such as smart features, app connectivity, and energy-efficient designs. By leveraging these advancements, OEMs can offer cutting-edge products that appeal to tech-savvy consumers.

ScalabilityAs an OEM grows, the ability to scale production is crucial. Turnkey services are designed to be scalable, allowing OEMs to increase or decrease production as demand fluctuates. This flexibility ensures that the supply chain remains robust and responsive to market changes.

Environmental SustainabilityWith increasing consumer awareness of environmental issues, sustainable practices are becoming more important. Turnkey OEM services can incorporate eco-friendly materials and manufacturing processes, appealing to consumers who value sustainability and helping OEMs to position their brand as environmentally responsible.

Expertise and SupportTurnkey services provide OEMs with access to a team of experts who specialize in air fryer design and manufacturing. This support network can offer valuable insights, troubleshoot technical issues, and provide ongoing assistance, ensuring that the OEM’s product line remains competitive and up-to-date.

Financial StabilityInvesting in the development and production of a new product can be risky. Turnkey UL certified air fryer OEM services often offer financial stability through long-term contracts and cost predictability. This can provide OEMs with the peace of mind they need to focus on other aspects of their business.

In conclusion, turnkey UL certified air fryer OEM services offer a comprehensive suite of benefits that can significantly enhance an OEM’s ability to compete in the market. From streamlined production and quality assurance to customization and cost savings, these services provide a solid foundation for success in the air fryer industry.

The air fryer market has been experiencing a surge in demand, driven by the growing interest in healthier cooking methods and convenience. Consumers are increasingly seeking appliances that offer both health benefits and the ability to create delicious food in less time. As such, market trends and consumer preferences are shifting, influencing the direction of the air fryer industry.

Emphasis on Health and WellnessWith health concerns on the rise, consumers are gravitating towards air fryers as a healthier alternative to traditional deep frying. This trend is supported by research highlighting the lower fat content in air-fried foods compared to their deep-fried counterparts. As a result, manufacturers are focusing on emphasizing this health benefit in their marketing strategies.

Convenience and Time-Saving FeaturesIn today’s fast-paced world, convenience is king. Consumers are looking for air fryers that can save them time while still delivering a quality meal. Features like programmable settings, easy-to-clean designs, and rapid preheating are becoming increasingly popular, as they allow users to cook with minimal effort and clean up with ease.

Customization and PersonalizationThe rise of smart appliances has also led to a demand for personalized cooking experiences. Consumers are seeking air fryers that can cater to their specific needs, whether that’s cooking for one or managing various dietary preferences. Customizable cooking modes and recipes are becoming a standard offering among air fryer brands.

Design and AestheticsGone are the days when kitchen appliances were strictly utilitarian. Today, consumers are looking for appliances that not only function well but also look good in their kitchen. Air fryer manufacturers are responding by creating sleek, modern designs that complement kitchen decor, from minimalist stainless steel to colorful, vibrant models.

Smart Technology IntegrationAs technology advances, so does its integration into everyday products. Smart air fryers with Wi-Fi connectivity are becoming more common, allowing users to control their appliances remotely through smartphone apps. This integration also enables features like recipe recommendations and smart home integration, which are attracting tech-savvy consumers.

Versatility andOne of the most appealing aspects of air fryers is their versatility. Consumers are looking for appliances that can perform multiple functions, such as air frying, roasting, baking, and even dehydrating. Multi-functional air fryers that can replace several appliances on a countertop are gaining popularity, as they offer a cost-effective solution for space-conscious cooks.

Environmental ConsiderationsSustainability is another growing concern among consumers. Air fryers, which use less energy than traditional ovens and deep fryers, are becoming more attractive to eco-conscious shoppers. Additionally, manufacturers are exploring environmentally friendly materials and sustainable practices in their production processes.

Competitive PricingWith the increasing competition in the air fryer market, consumers are also looking for competitive pricing. Value-for-money products that offer advanced features without a premium price tag are likely to capture a larger market share. As a result, brands are focusing on cost optimization and value engineering to meet these demands.

Popularity of Healthy Cooking RecipesThe air fryer industry is benefitting from the growing popularity of healthy cooking recipes. Social media platforms and recipe websites are brimming with air fryer-friendly dishes, which in turn generate interest in the appliances themselves. Manufacturers are leveraging this content to showcase their products and highlight the wide range of meals that can be prepared using their air fryers.

Expansion into New MarketsThe air fryer market is not limited to mature markets; it’s expanding into emerging economies as well. As consumers in these regions become more health-conscious and their purchasing power grows, the demand for air fryers is expected to rise. This expansion presents opportunities for manufacturers to tap into new customer bases and markets.

The combination of these trends and preferences is shaping the future of the air fryer industry, pushing manufacturers to innovate and evolve their products to meet the changing demands of consumers around the world.

In the ever-evolving world of kitchen appliances, the air fryer has emerged as a game-changer, and OEMs (Original Equipment Manufacturers) have played a pivotal role in shaping its success. Let’s delve into some case studies that showcase the fruits of their collaborative efforts.

The rise of the compact, energy-efficient air fryer was a direct response to consumer demands for healthier cooking options. One such project involved a partnership between an established OEM and a fast-growing consumer electronics brand. They developed a line of air fryers that featured advanced technologies such as smart temperature control and customizable cooking programs.

The air fryer’s sleek design and intuitive interface were a hit with consumers, who appreciated the ease of use and the ability to enjoy fried foods with significantly less oil. This project was a testament to the OEM’s ability to integrate cutting-edge features into a product that was both aesthetically pleasing and functional.

Another successful collaboration saw an OEM team up with a health-focused brand to create an air fryer that catered to the needs of individuals with dietary restrictions. The result was a model that offered pre-programmed settings for low-calorie, low-fat cooking, making it easier for consumers to adhere to their health goals without compromising on taste.

The project required a deep understanding of the market and the ability to tailor the product to meet specific consumer preferences. The OEM’s expertise in food dehydration and roasting techniques was crucial in developing an air fryer that could handle a wide range of recipes, from crispy French fries to perfectly roasted vegetables.

One notable case study involved an OEM that partnered with a startup aiming to disrupt the air fryer market with a unique approach to cooking. The startup sought to differentiate its product by focusing on the air fryer’s ability to preserve nutrients and flavors in foods. The OEM, in turn, leveraged its experience in heat distribution technology to create a model that could achieve this.

The end result was an air fryer that not only reduced cooking times but also maintained the nutritional integrity of the food. This project highlighted the OEM’s ability to innovate and adapt to new market demands, ensuring that the final product was not only competitive but also revolutionary.

Consumer preferences have also led to the development of air fryers that are not just kitchen appliances but also smart home companions. An OEM collaborated with a tech giant to create an air fryer that could be controlled via a smartphone app, allowing users to monitor and adjust cooking settings remotely.

This project required a seamless integration of the air fryer with existing smart home ecosystems. The OEM’s success was measured by the number of users who adopted the product and the positive feedback regarding its ease of integration and reliability.

In another instance, an OEM worked with a global brand to address the need for portable air fryers that could be used both at home and on the go. The challenge was to design a compact, lightweight device that didn’t compromise on performance. The result was a travel-sized air fryer that could fit in a backpack and still deliver restaurant-quality fried food.

This project underscored the OEM’s commitment to innovation and the importance of staying ahead of consumer trends. The portable air fryer was not only well-received by travelers but also by health-conscious individuals looking for a way to enjoy their favorite snacks without the guilt.

The case studies of successful turnkey air fryer projects demonstrate the dynamic nature of the industry and the pivotal role that OEMs play in driving innovation. From health-conscious features to smart technology and portable solutions, these projects are a testament to the OEMs’ ability to anticipate and fulfill consumer needs, one fry at a time.

The air fryer market has seen a surge in innovation, driven by consumer demand for healthier cooking alternatives. These compact appliances have transformed the way we approach cooking, making it easier to enjoy crispy, golden-brown results without the excessive oil traditionally used in frying. Let’s delve into some of the key innovations shaping the air fryer design landscape.

In recent years, the air fryer has evolved from a simple countertop appliance to a versatile tool with a range of features designed to enhance cooking experience. One such innovation is the introduction of variable temperature settings. Users can now control the exact heat level, ensuring that delicate vegetables cook to perfection while chicken and fish achieve the desired level of crispiness.

Smart technology has also made its way into air fryer design, with models now offering programmable timers and remote controls via smartphone apps. This allows users to set their appliances to start cooking at a specific time or to turn off once the food is ready, making meal preparation more convenient and efficient.

Another notable innovation is the development of multi-functional air fryers. These appliances can not only fry but also bake, roast, and even dehydrate food. The inclusion of these additional functions has expanded the versatility of the air fryer, making it a more attractive option for those looking for a single appliance to handle a variety of cooking tasks.

Design-wise, air fryers have become sleeker and more aesthetically pleasing. Modern models often feature digital displays and intuitive interfaces, making them not just a functional appliance but also a stylish addition to any kitchen. The use of materials like stainless steel and glass has also helped to elevate the appearance of these devices.

The inclusion of non-stick coatings has been a game-changer for air fryers. These coatings ensure that food doesn’t stick to the basket, making cleaning easier and reducing the need for additional fats. Some newer models even incorporate a self-cleaning feature, which uses high heat to burn off any remaining food particles.

One of the most significant innovations in air fryer design is the focus on energy efficiency. Modern air fryers use less energy than traditional deep fryers, which not only benefits the environment but also saves on electricity bills. This has made air fryers a more sustainable choice for health-conscious consumers.

In terms of health benefits, air fryers have gained popularity due to their ability to cook food with significantly less oil. This reduction in fat content has made air-fried foods a healthier alternative to deep-fried ones, without compromising on taste and texture. The ability to air-fry a wide variety of foods, from vegetables to meats, has opened up new possibilities for low-fat cooking.

As the air fryer market continues to grow, manufacturers are exploring new ways to make these appliances even more user-friendly. One such innovation is the inclusion of recipe guides and built-in cooking modes that automatically adjust the temperature and cooking time for specific dishes. This feature takes the guesswork out of air frying, allowing even the most inexperienced cooks to achieve professional results.

The rise of eco-conscious consumers has led to the development of air fryers that are not only energy-efficient but also sustainable. Some brands are now using recycled materials for their appliances, and others are designing products that are easier to recycle at the end of their lifespan.

The future of air fryer design is likely to focus on further enhancing the user experience. This could include features like voice control, integration with smart home systems, and even air fryers that can be controlled via virtual reality, allowing users to “cook” in a simulated kitchen environment.

Another trend we might see is the development of air fryers that can be used both at home and on the go. Portable air fryers could become a popular choice for campers, travelers, and those with small kitchens, offering the convenience of a countertop appliance without the need for a constant power source.

In conclusion, the air fryer industry is ripe with innovation, driven by consumer demand for healthier, more efficient, and versatile kitchen appliances. As technology continues to advance, we can expect to see even more creative and user-friendly designs hitting the market in the coming years.

Understanding the nuances of the air fryer market, one cannot overlook the significant role that Original Equipment Manufacturers (OEMs) play. These companies are the backbone of the industry, shaping the landscape with their innovative designs and efficient production processes. Here’s a closer look at how OEMs contribute to the air fryer industry.

OEMs are pivotal in driving the evolution of air fryer technology. They take raw components and transform them into user-friendly appliances that cater to diverse consumer needs. By integrating cutting-edge features, such as smart technology and eco-friendly materials, OEMs ensure that air fryers not only meet safety standards but also offer a seamless cooking experience.

Customization is another area where OEMs excel. They work closely with brands to create air fryers that align with specific market demands and brand identities. This collaboration allows for the development of unique products that stand out in a crowded marketplace, offering consumers a variety of options to choose from.

The air fryer industry is a testament to the power of innovation. OEMs are at the forefront of this movement, pushing the boundaries of what’s possible with their designs. From compact, countertop models to multifunctional kitchen systems, the variety of air fryers available today is a direct result of the creativity and technical expertise brought to the table by OEMs.

Quality control is a non-negotiable aspect of OEM operations. They ensure that every air fryer they produce meets stringent safety and performance standards. This commitment to excellence not only protects consumers but also builds trust in the brand, reinforcing the reputation of the OEM as a reliable partner.

In the competitive air fryer market, OEMs often serve as a strategic advantage for brands. By offering turnkey solutions, they take care of the entire manufacturing process, from design to distribution. This comprehensive approach allows brands to focus on marketing and customer service, rather than getting bogged down by production details.

Collaboration with OEMs also enables brands to tap into a wealth of industry knowledge. These manufacturers stay abreast of the latest trends, regulatory changes, and consumer preferences, ensuring that their products remain relevant and competitive.

When it comes to sustainability, OEMs are leading the charge. They are increasingly incorporating eco-friendly materials and energy-efficient designs into their air fryers, addressing the growing demand for environmentally conscious products. This shift not only benefits the planet but also resonates with consumers who are more conscious of their ecological footprint.

Innovation in air fryer design is not just about adding new features; it’s about improving the overall user experience. OEMs are focused on creating appliances that are intuitive, easy to clean, and versatile enough to handle a wide range of cooking tasks. This user-centric approach is essential in a market where convenience and functionality are key selling points.

The rise of the air fryer industry has also sparked a surge in cross-industry partnerships. OEMs are collaborating with foodservice providers, health organizations, and even tech companies to create integrated solutions that cater to different market segments. These collaborations can lead to groundbreaking products that redefine the air fryer category.

As the air fryer market continues to grow, OEMs are also addressing the challenges of scalability and logistics. They are investing in advanced manufacturing facilities and supply chain management systems to ensure that they can meet the increasing demand without compromising on quality.

The role of OEMs in the air fryer industry is multifaceted, encompassing innovation, quality assurance, customization, and strategic partnerships. Their ability to adapt to market changes and consumer preferences is what keeps the industry dynamic and thriving. By staying ahead of the curve, OEMs are not just contributing to the air fryer market’s success but also shaping its future.