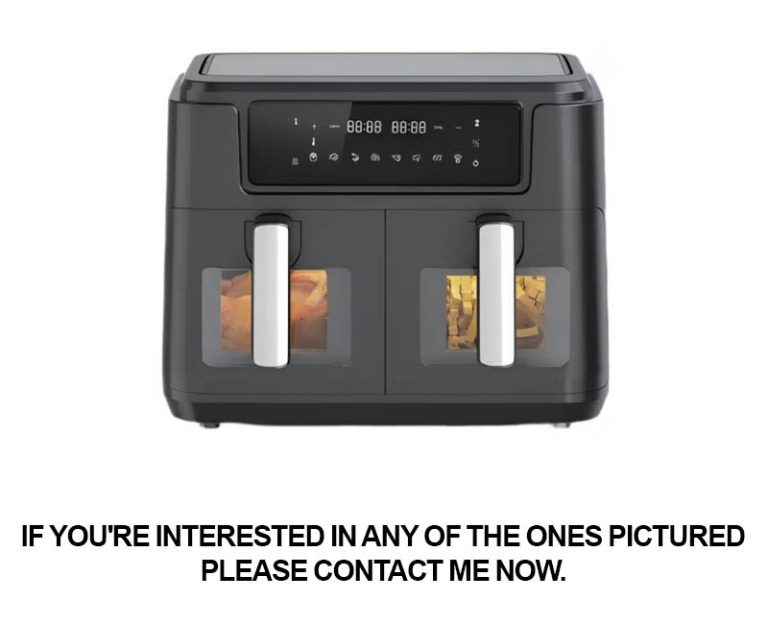

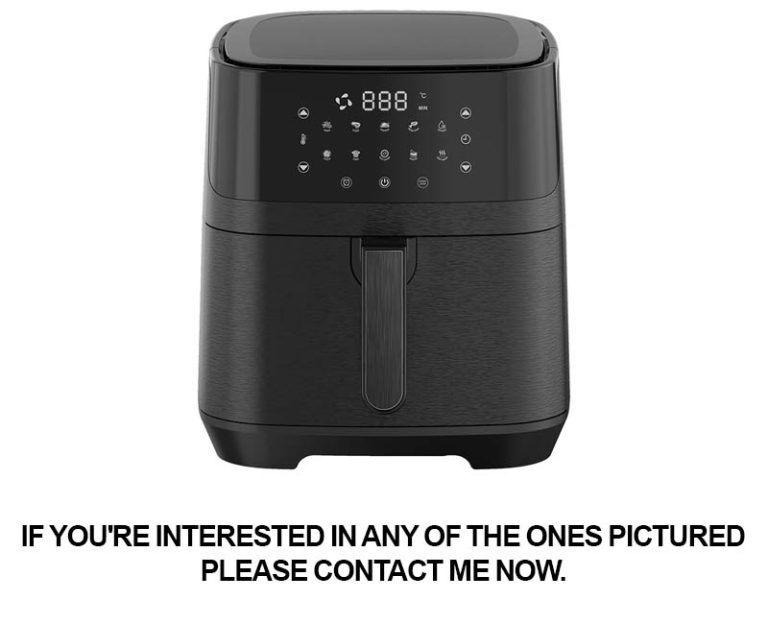

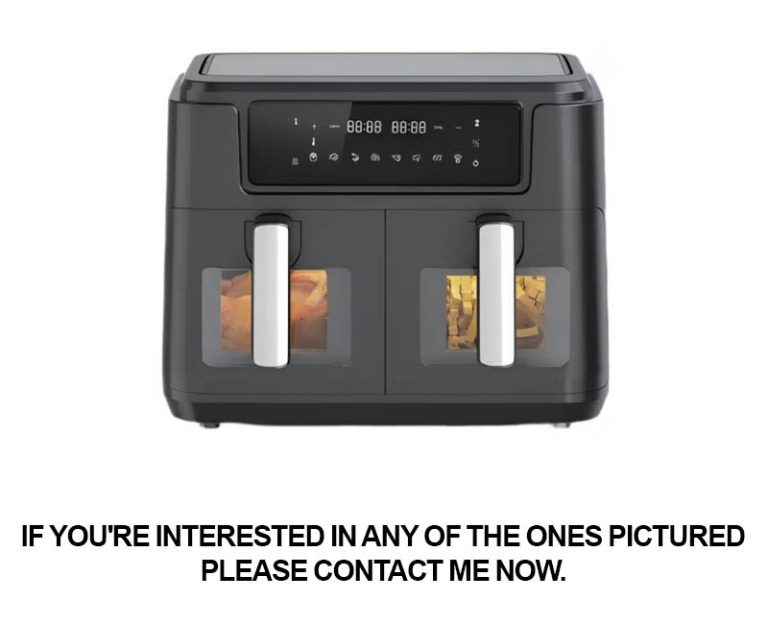

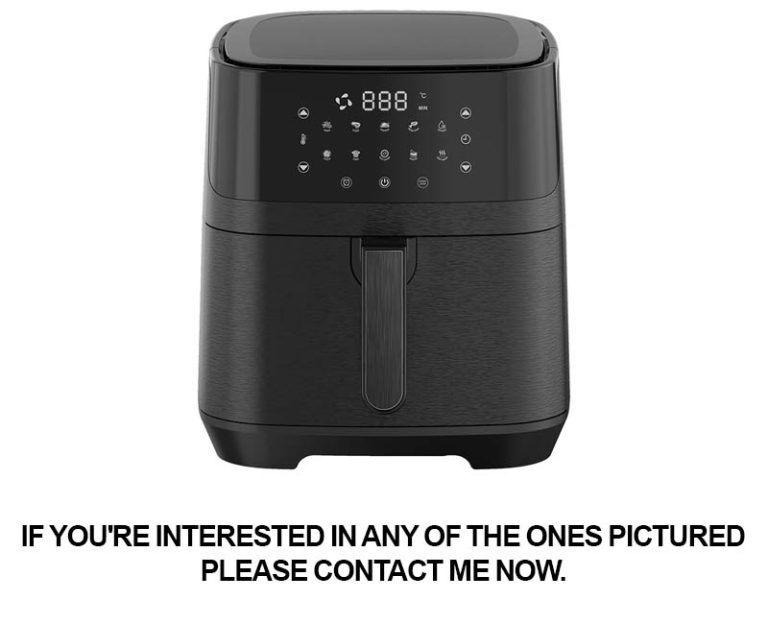

The 30-Day Air Fryer Challenge, a popular health and wellness initiative, has highlighted the transformative impact of air fryers as a convenient and healthier cooking alternative. Chinese Original Design Manufacturers (ODMs) have played a pivotal role in this market’s growth, producing innovative and efficient air fryers that cater to diverse consumer needs. These ODMs not only design sleek, multi-functional appliances but also integrate smart technology and eco-friendly materials, making air fryers a must-have kitchen appliance for those seeking convenient and guilt-free cooking.

The air fryer market’s rapid growth necessitates a keen understanding of selecting the right turnkey UL certified air fryer OEM partner. These specialized manufacturers are pivotal in the industry, crafting efficient and safe appliances that cater to the evolving demands of cooking and health-conscious consumers. By offering turnkey solutions, they streamline production, ensure quality control, and facilitate compliance with stringent safety standards like UL certification. This collaborative approach empowers brands to innovate, customize, and deliver high-quality air fryers that not only meet but exceed market expectations, enhancing the cooking experience with convenience and health benefits.

The NSF Certified 1800W Air Fryer is a game-changer in kitchen appliances, offering a healthier, more efficient alternative to traditional deep-frying. This innovative air fryer boasts rapid air circulation for crispy, golden results with minimal oil, redefining cooking with its versatility for frying, baking, roasting, and even dehydrating. Its sleek design, NSF certification for safety and quality, and energy-efficient operation make it a must-have for those seeking a healthier lifestyle and a smart, eco-friendly cooking solution.

In the ever-evolving kitchen appliance market, ETL listed commercial units stand out as a symbol of quality and safety. These advanced appliances integrate cutting-edge technology, focusing on efficiency, sustainability, and smart design. The European and American markets lead this transformation, with a surge in innovative kitchen appliances that not only enhance daily life but also cater to eco-conscious consumers. ETL listed commercial units, with their rigorous safety standards and advanced features, are shaping the future of kitchen technology, ensuring a seamless blend of convenience, health, and environmental responsibility.

The FOB Ningbo air fryer supplier is at the forefront of the culinary revolution, offering innovative air fryers that are transforming cooking practices. Hailing from Ningbo, China, these suppliers provide high-quality, health-conscious appliances that use minimal oil to achieve crispy, delicious results. Their commitment to quality and cutting-edge technology has made Ningbo air fryers a global favorite, reshaping the way we cook and enjoy our meals.

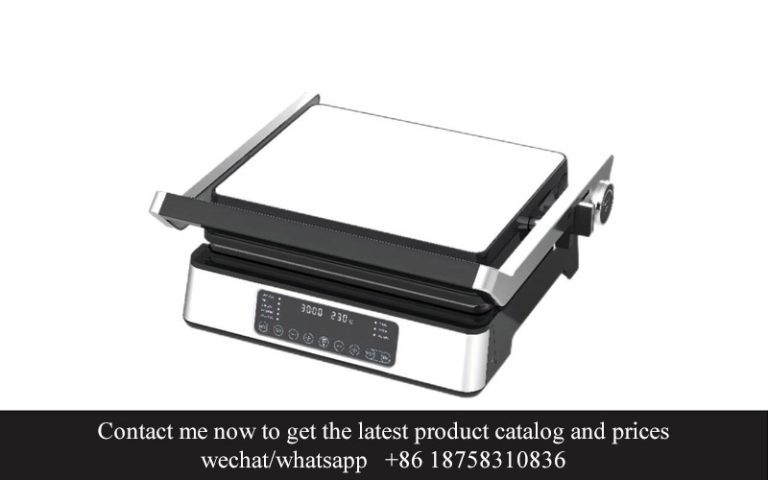

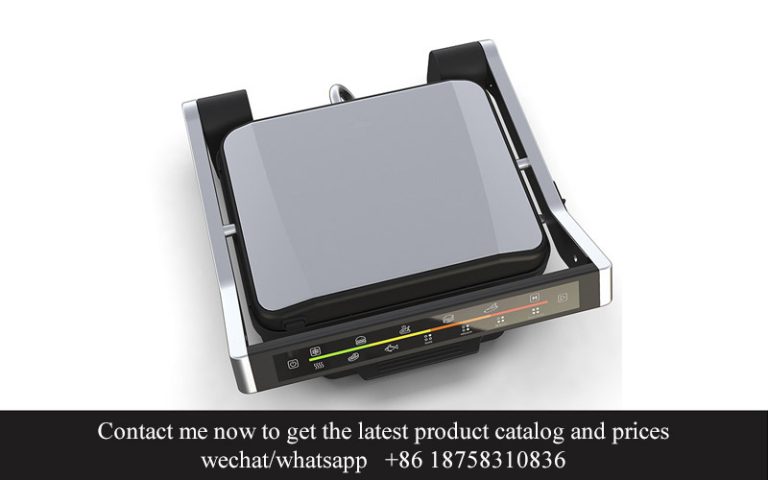

In the dynamic world of kitchen appliances, the demand for efficiency and innovation is soaring. CE-EMC compliant 2200W appliances are leading the charge, offering superior cooking performance and energy savings. These cutting-edge devices, like high-powered toasters and efficient blenders, are reshaping kitchen experiences by combining advanced technology with practicality. As consumers seek out smart, energy-efficient solutions, the market for these premium kitchen appliances continues to expand, promising a future where cooking is not only faster and more convenient but also eco-friendly and tailored to individual needs.

The Moscow Air Fryer Manufacturer has emerged as a leader in the kitchen appliance market with its innovative air fryers. These devices, designed to promote healthier cooking, have gained popularity for their ability to mimic the crispy texture of fried foods with significantly less oil. Known for their sleek design, advanced technology, and user-friendly features, these air fryers have become a staple in many kitchens. The company’s commitment to health, efficiency, and sustainability is evident in their eco-friendly designs and energy-saving technology. As the demand for convenient and nutritious cooking solutions continues to rise, the Moscow Air Fryer Manufacturer is well-positioned to continue shaping the future of air fryer technology and cooking habits.

The commercial air fryer factory is at the forefront of culinary innovation, manufacturing high-quality air fryers that revolutionize cooking methods. These energy-efficient appliances, known for their health benefits, have become a staple in kitchens worldwide. As demand grows, manufacturers continuously push the boundaries of design and technology, offering versatile cooking solutions that cater to a wide range of culinary needs, from crispy fried foods to roasted and grilled dishes. This surge in popularity is testament to the factory’s commitment to excellence in manufacturing, ensuring that air fryers are not just cooking appliances, but versatile kitchen companions that enhance both taste and health.

The rise of the restaurant-grade air fryer has transformed home cooking, thanks to the innovative technology and durability crafted in the state-of-the-art restaurant-grade air fryer factory. These advanced appliances offer a healthier, oil-reduced alternative to traditional frying, with features like precise temperature control and versatile cooking modes. Their sleek design and eco-friendly operation make them a must-have for any modern kitchen, appealing to health-conscious consumers and culinary enthusiasts alike. The factory’s commitment to quality and innovation ensures that these air fryers are not just appliances, but game-changers in the world of cooking.

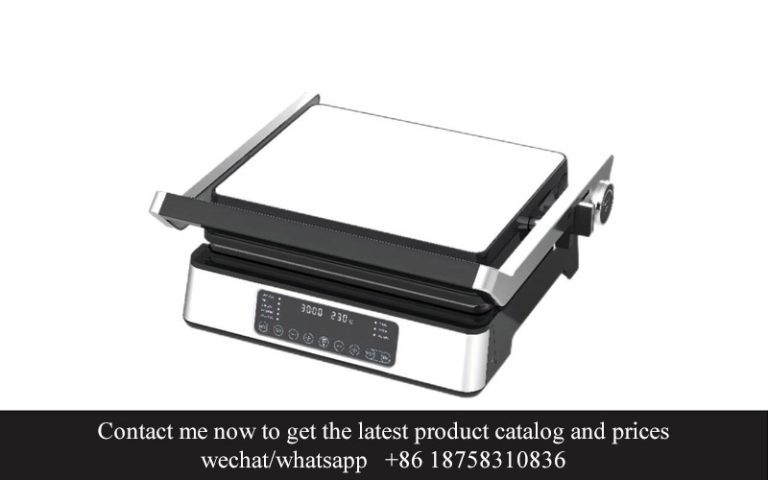

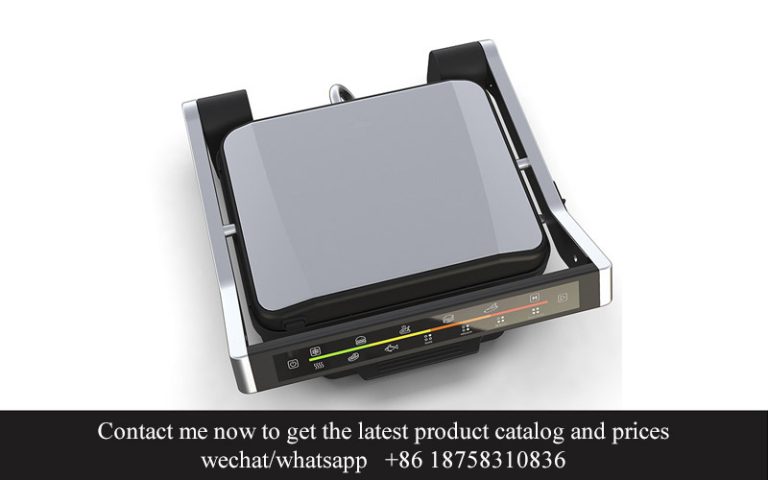

The heavy-duty sandwich press factory stands as a beacon of culinary innovation, crafting appliances that redefine the art of sandwich-making. These robust presses are not just tools but symbols of precision and quality. With features like adjustable pressure and non-stick surfaces, they ensure perfection in every bite. Their durable construction and sleek design make them a must-have for any kitchen, transforming the humble sandwich into a gourmet delight. The factory’s commitment to excellence is evident in the array of features that cater to both home chefs and professional kitchens, making the heavy-duty sandwich press an indispensable appliance for those who demand the best.