Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As technology continues to reshape our lives, the kitchen has not been left untouched. Among the many advancements that have transformed this once-sterile room into a hub of innovation, the rise of the automated air fryer assembly line stands out as a testament to human ingenuity and the relentless pursuit of efficiency. This article delves into the evolution of kitchen appliances, the need for automation, the innovations behind the automated assembly line, and the myriad benefits it brings to the market and consumers alike. We’ll also explore future trends, examine case studies of successful implementations, and address the challenges and solutions in this rapidly evolving sector.

The evolution of kitchen appliances has been a remarkable journey that reflects the ever-growing advancements in technology and design. From the early days of simple cookware to the sophisticated, smart appliances of today, the kitchen has transformed into a hub of innovation and convenience.

In the beginning, cooking was a rudimentary process, requiring little more than fire, pots, and pans. The advent of the kitchen stove in the 19th century marked a significant leap forward, allowing for greater control over heat and the ability to cook a wider variety of dishes. This early stage of kitchen appliances was all about survival and convenience.

As the 20th century dawned, so did a surge of technological innovation. The electric oven replaced the open hearth, offering a cleaner and more controlled cooking environment. The refrigerator, which first appeared in the early 20th century, revolutionized food storage, extending the shelf life of perishables and making meal planning more manageable.

The 1950s and 1960s saw the rise of the “white goods,” a term for the standard kitchen appliances that included dishwashers, washing machines, and dryers. These appliances freed up time for families, allowing more time for leisure and less for housework. The era of convenience cooking was in full swing.

The 1970s and 1980s brought about further advancements with the introduction of the microwave oven, which drastically reduced cooking times and changed the way people thought about meal preparation. The microwave was not only a convenience but also a space-saving solution, as it took up less room than a traditional oven.

As technology progressed, appliances became more integrated into home automation systems. The 1990s saw the birth of smart appliances, which could be controlled remotely via a computer or smartphone. This era marked the beginning of the kitchen becoming a connected space, with appliances capable of communicating with each other and learning from user habits.

The 21st century has been a period of rapid innovation, with the introduction of the smart kitchen. Today’s kitchen appliances are not just tools for cooking and cleaning; they are connected devices that can provide dietary advice, track food expiration dates, and even order more groceries when supplies run low. From ovens that can adjust their settings based on the recipe to refrigerators that can display recipes and shopping lists, the kitchen has become a testament to how far technology has come.

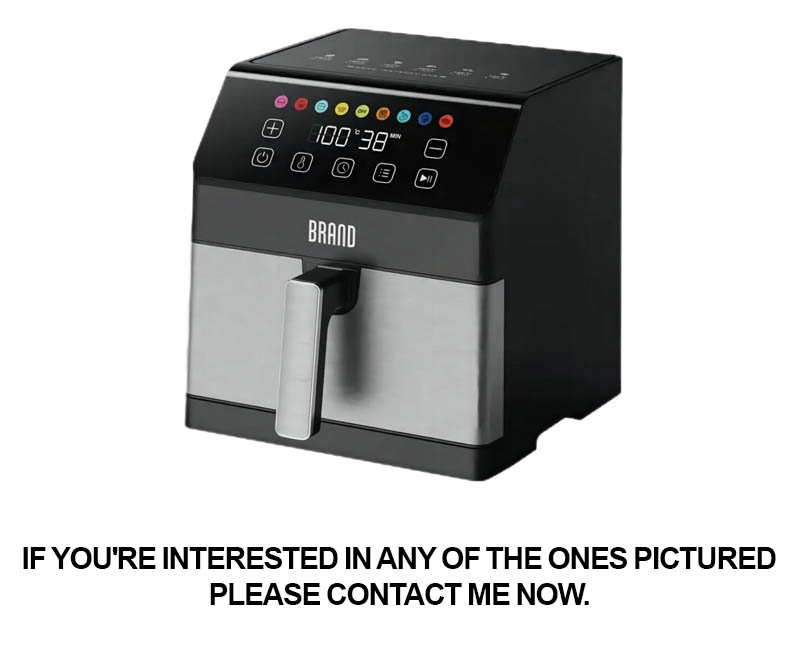

One of the most significant developments in recent years has been the rise of healthier cooking options. The air fryer, for instance, has gained popularity as a healthier alternative to traditional deep-frying. It uses hot air to circulate around food, resulting in crispy textures with up to 80% less fat than traditional frying methods.

The evolution of the air fryer itself is a story of innovation. Early models were bulky and inefficient, but through continuous refinement, they have become sleek, compact, and highly effective. The automated assembly line has played a crucial role in this evolution, ensuring that each air fryer is assembled with precision and efficiency.

As we look to the future, it’s clear that kitchen appliances will continue to evolve. We can expect to see more personalized and health-focused technologies, with appliances that can not only prepare food but also analyze nutritional content and provide dietary recommendations. The kitchen of the future will be a seamless blend of culinary expertise, technological sophistication, and user-friendly design.

In the ever-evolving landscape of kitchen appliances, the demand for efficiency, precision, and consistency has surged. This shift has given rise to a critical need for automation in the production of these devices. The traditional methods of assembling kitchen appliances, once sufficient, now struggle to keep pace with the modern consumer’s expectations.

The rapid pace of technological advancements has led to a market that craves innovation and reliability. Consumers no longer settle for appliances that merely perform their basic functions; they seek devices that are intuitive, durable, and energy-efficient. To meet these demands, manufacturers must streamline their production processes, and this is where automation steps in.

The complexity of modern kitchen appliances, particularly air fryers, has increased dramatically. These devices are not just simple cookers; they are sophisticated machines with multiple components, intricate electrical systems, and precise temperature controls. The manual assembly of such devices is not only time-consuming but also prone to errors that can compromise the performance and safety of the end product.

Moreover, the competitive nature of the market requires manufacturers to produce at scale while maintaining high quality standards. This is nearly impossible to achieve with traditional, labor-intensive methods. Automation allows for the consistent production of high-quality air fryers at a rate that manual labor simply cannot match.

Another driving factor behind the need for automation is the cost-effectiveness it offers. While the initial investment in automation technology can be substantial, the long-term savings are significant. By reducing labor costs, minimizing defects, and improving productivity, manufacturers can achieve economies of scale that were once unattainable.

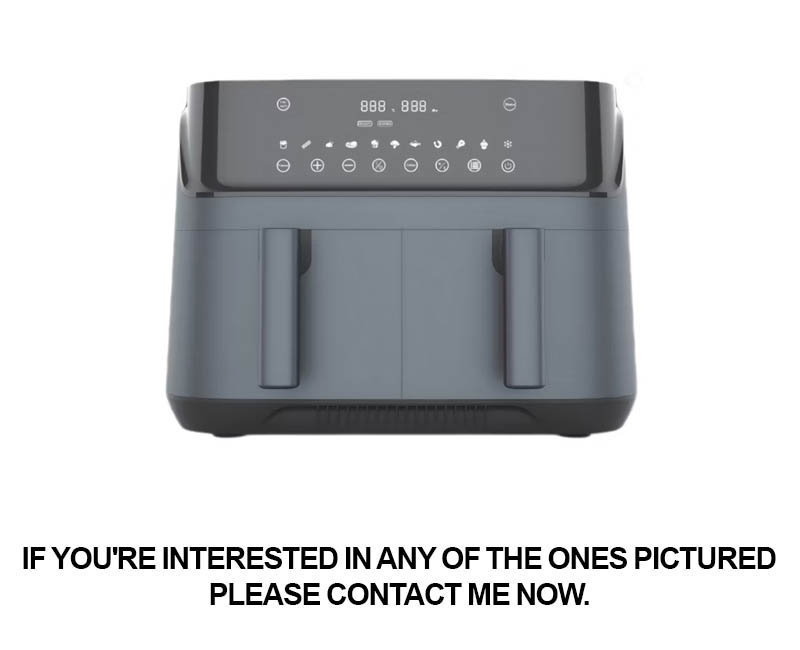

The demand for personalization and customization in kitchen appliances has also surged. Consumers are looking for appliances that can be tailored to their specific needs and preferences. Automation can facilitate this by allowing for the quick and efficient production of a wide range of air fryer models with varying features and capacities.

Furthermore, the global supply chain has become increasingly complex, with components and parts often sourced from multiple suppliers around the world. Automation can help manage this complexity by ensuring that the assembly line can handle a diverse array of components with ease, reducing the risk of delays and disruptions.

Environmental concerns have also played a role in the push for automation. The production of kitchen appliances, particularly air fryers, involves the use of materials and energy. Automation can lead to more sustainable practices by optimizing energy usage, reducing waste, and enabling recycling and reuse of materials.

Lastly, the need for automation in the kitchen appliance industry is driven by the desire for continuous improvement. As new materials, technologies, and design concepts emerge, manufacturers must be able to adapt quickly. Automation provides the flexibility to experiment with new ideas and integrate them into production without disrupting the entire process.

In summary, the need for automation in the kitchen appliance industry, particularly in the assembly of air fryers, is multifaceted. It is driven by the demand for high-quality, personalized products, the need to reduce costs and improve efficiency, and the pressure to adapt to a rapidly changing market landscape. As automation continues to evolve, it will undoubtedly play a pivotal role in shaping the future of kitchen appliances.

In the realm of kitchen appliances, the evolution of the air fryer has been nothing short of revolutionary. From the traditional deep-frying method to a healthier, oil-reduced alternative, the air fryer has captured the hearts and kitchens of consumers worldwide. However, as demand for these compact and efficient appliances surged, the need for a more efficient manufacturing process became apparent. Enter the automated air fryer assembly line, a marvel of modern engineering that has transformed the way these devices are produced.

The automated assembly line for air fryers is a testament to innovation and precision. It starts with the arrival of raw materials, which are meticulously sorted and prepared for the manufacturing process. Here are some of the key innovations that have made this assembly line a beacon of efficiency and quality:

The automated air fryer assembly line is not just a series of machines working in harmony; it is a symbol of human ingenuity and the relentless pursuit of efficiency. By combining robotics, advanced technologies, and a focus on quality, this assembly line has set a new standard for the production of kitchen appliances, making the air fryer more accessible and reliable than ever before.

The shift towards automation in the air fryer assembly line has brought a multitude of benefits, reshaping the landscape of kitchen appliance manufacturing. Here’s a closer look at the advantages this transformation brings:

Precision and Consistency– The precision of automated assembly lines ensures that every air fryer produced is uniform in design and functionality. This level of consistency is nearly impossible to achieve with manual labor alone, reducing the likelihood of defects and ensuring a high-quality product every time.

Increased Efficiency– Automation streamlines the production process, reducing the time it takes to assemble an air fryer. This efficiency isn’t just about speed; it’s also about the ability to handle larger volumes without sacrificing quality or increasing labor costs.

Reduced Labor Costs– While automation may seem to increase costs upfront, over time, it can significantly reduce labor expenses. With fewer workers needed on the assembly line, companies can save on wages, benefits, and training costs.

Enhanced Safety– Manual assembly lines can be dangerous, with workers handling sharp tools and moving parts. Automation minimizes the risk of workplace accidents, as machines take over tasks that could otherwise pose a hazard.

Continuous Operation– Automated systems can run 24⁄7 without breaks, which means production never stops. This continuous operation ensures a steady flow of air fryers, meeting the demands of a global market that operates around the clock.

Customization and Flexibility– Modern assembly lines can be programmed to adapt to different models and specifications of air fryers. This flexibility allows manufacturers to quickly switch between product lines without significant downtime or retooling.

Improved Traceability– Each air fryer that comes off an automated assembly line can be tracked from its components to its final destination. This traceability is crucial for quality control, warranty claims, and recalls, ensuring that issues can be addressed promptly.

Energy and Resource Efficiency– Automated systems are designed to be energy-efficient, using less power than traditional methods. Furthermore, they can optimize the use of materials, reducing waste and the environmental impact of production.

Enhanced Quality Control– With automated inspections and testing integrated into the assembly process, the quality of each air fryer is closely monitored. This results in a higher percentage of defect-free products and less need for rework or disposal.

Scalability– As demand for air fryers grows, an automated assembly line can be easily scaled up to meet increased production needs. This scalability is essential for businesses looking to expand without a proportional increase in costs.

Long-Term Cost Savings– Although the initial investment in automation can be substantial, the long-term savings on labor, waste, and improved product quality often outweigh the costs. This makes automation a financially sound decision for the future of air fryer manufacturing.

Market Responsiveness– The ability to quickly adjust production to market trends and consumer demands is a significant advantage of automated assembly lines. Manufacturers can now respond swiftly to changes, ensuring they remain competitive.

Innovation and Continuous Improvement– Automation encourages innovation as manufacturers seek to improve the assembly process. This drive for continuous improvement leads to more efficient and advanced systems over time.

By embracing automation in the air fryer assembly line, manufacturers are not just keeping up with the times; they are setting the pace for the future of kitchen appliance production. The benefits are clear, and the industry is already reaping the rewards of this technological shift.

The journey of an air fryer from raw components to a finished product on an automated assembly line is a marvel of modern engineering and efficiency. Let’s take a peek into this fascinating process.

This step-by-step automation not only streamlines the production of air fryers but also ensures a high level of consistency and quality. The process is a testament to the power of technology in transforming traditional manufacturing into a precision-driven industry.

In the era of automation, quality control in the manufacturing process of air fryers has evolved significantly. Here’s an in-depth look at how this transformation is shaping up:

The Precision of SensorsAutomated systems are equipped with advanced sensors that meticulously monitor the assembly process. These sensors detect the presence of components, measure their dimensions, and verify their alignment, ensuring that every part meets the exact specifications. This level of precision minimizes the risk of defects and guarantees that the final product is of the highest quality.

Robust Testing ProtocolsAutomated testing protocols have been developed to scrutinize each air fryer at various stages of production. These protocols include drop tests, leak tests, and functional tests to ensure that every fryer operates as intended. The automated nature of these tests means that they are conducted consistently and with uniformity, reducing the likelihood of human error.

Real-Time MonitoringWith automation, quality control is no longer a one-time inspection at the end of the line. Instead, it’s a continuous process that keeps a close eye on the entire assembly. Real-time monitoring systems alert operators to any anomalies or deviations from the standard, allowing for immediate intervention before a defect can affect a larger batch.

AI-Driven AnalysisArtificial intelligence (AI) has become a powerful tool in the quality control arsenal. AI algorithms can analyze data from sensors and testing equipment to predict potential failures or defects. By learning from historical data, these systems can provide predictive maintenance recommendations, preventing costly downtime and ensuring that the assembly line runs smoothly.

Customizable Quality ParametersThe automated quality control systems are not one-size-fits-all. They can be customized to meet the specific quality parameters of different air fryer models. This flexibility ensures that each product line can be tailored to meet the unique requirements of its target market, from the most basic to the most sophisticated features.

Enhanced TraceabilityIn the event of a quality issue, the traceability of products is crucial. Automated systems record every step of the assembly process, creating a detailed history for each unit. This level of traceability not only helps in identifying the root cause of a problem but also in recalling affected products swiftly and efficiently.

Employee EmpowermentWhile automation takes over many of the repetitive tasks, it also empowers employees to focus on more complex and value-added activities. With the assurance that basic quality checks are being handled by machines, workers can now dedicate their time and expertise to tasks that require a human touch, such as troubleshooting and innovation.

Reduced Waste and CostsOne of the most significant benefits of automated quality control is the reduction in waste. By catching defects early in the process, manufacturers can prevent the production of faulty products, saving on materials and labor costs. Additionally, the precision of automated systems means fewer products need to be discarded due to non-compliance with quality standards.

Global Standards ComplianceIn a global market, adhering to international quality standards is essential. Automated quality control systems are designed to meet these standards, ensuring that products are not only of high quality but also compliant with regulations across different regions and countries.

Continuous ImprovementThe age of automation has ushered in a culture of continuous improvement. With the ability to analyze vast amounts of data and make real-time adjustments, manufacturers can constantly refine their processes, leading to better products and customer satisfaction.

In conclusion, the age of automation has transformed quality control in the air fryer assembly line. The integration of advanced technologies and AI has not only improved the efficiency and consistency of production but has also raised the bar for product quality, ensuring that consumers receive a reliable and high-performing product every time.

In the ever-evolving landscape of kitchen appliances, the rise of the automated air fryer assembly line has sparked a significant shift in both the market and consumer behavior. This transformation isn’t just about faster production; it’s about redefining what consumers expect from their kitchen gadgets.

The market dynamics have been reshaped with the advent of automated assembly lines. Once a niche product, air fryers have now become a staple in many homes. The integration of automation has allowed manufacturers to scale up production without compromising on quality, leading to a surge in availability and accessibility. Retailers now stock a wider variety of air fryers, catering to different budgets and preferences.

Consumers are experiencing a newfound convenience and affordability. The streamlined production process has led to competitive pricing, making air fryers more accessible to a broader demographic. This accessibility has also introduced the product to new markets, particularly in regions where traditional cooking methods are prevalent. The market has seen a democratization of air fryers, where they are no longer a luxury item but a practical kitchen tool.

The rise of the automated assembly line has also influenced consumer expectations. With consistent, high-quality products rolling off the line, consumers have come to expect reliability and durability. The automation process ensures that each air fryer meets stringent quality standards, reducing the likelihood of defects and enhancing consumer satisfaction. This shift has created a ripple effect, with consumers now expecting similar levels of efficiency and quality in other kitchen appliances.

Brands have had to adapt to this changing landscape. They are now focusing on innovation not just in the product design but also in the user experience. Smart features, intuitive interfaces, and eco-friendly materials are becoming standard expectations. Consumers are no longer just looking for a cooking appliance; they’re seeking a lifestyle enhancement.

Moreover, the market is witnessing a surge in health-conscious consumers. The popularity of air fryers is closely tied to the growing interest in healthier cooking methods. Automated assembly lines have facilitated the production of air fryers with various functionalities, such as adjustable temperature settings and timers, which cater to the diverse needs of health-conscious consumers.

The automated air fryer assembly line has also paved the way for personalized products. Customizable options, such as different sizes, colors, and functionalities, are becoming more common. This shift towards personalization allows consumers to choose appliances that align with their individual tastes and lifestyles.

In the realm of sustainability, the impact of automation is undeniable. The efficient use of resources, reduced waste, and the ability to recycle materials are all outcomes of the automated assembly line. This has resonated with environmentally conscious consumers who are increasingly seeking out products that are eco-friendly and sustainable.

The market and consumer impact of the automated air fryer assembly line is a testament to the power of technology in driving change. It has not only revolutionized the way air fryers are produced but has also influenced how consumers interact with and perceive kitchen appliances. As technology continues to advance, we can expect this trend to expand, transforming the kitchen landscape further and setting new standards for innovation and consumer satisfaction.

The landscape of kitchen appliances is rapidly evolving, and the integration of automation into the assembly process is reshaping the industry. As we delve into the future, several trends and predictions are emerging that promise to further transform the way air fryers and other kitchen appliances are designed, produced, and consumed.

The integration of IoT (Internet of Things) technology is set to become more prevalent, allowing for real-time monitoring and predictive maintenance. Smart appliances that can communicate with each other and with the user will become the norm, offering personalized cooking experiences and energy efficiency. This interconnectedness will not only streamline the manufacturing process but also enhance the user experience.

Customization is another trend that’s gaining traction. With the ability to produce air fryers with varying features and capabilities, manufacturers can cater to a diverse range of consumer preferences. From different sizes and capacities to various cooking modes and temperature controls, the future of air fryer assembly will likely see a move towards mass customization.

Artificial Intelligence (AI) and machine learning are poised to play a significant role in optimizing the assembly line. By analyzing data from previous productions, AI can predict and prevent defects, reduce waste, and improve overall efficiency. This level of intelligence will enable manufacturers to create more reliable and durable products.

Sustainability will continue to be a driving force in the industry. As consumers become more environmentally conscious, there will be a growing demand for energy-efficient and recyclable appliances. The assembly lines of the future will need to adapt to incorporate green practices, from the materials used in the appliances to the energy sources powering the manufacturing process.

3D printing technology could revolutionize the way air fryers are assembled. By printing components on demand, manufacturers can reduce inventory costs and lead times. This technology allows for the creation of complex geometries that might be difficult or expensive to produce using traditional methods. It also opens the door to localized production, reducing transportation costs and environmental impact.

In the realm of materials, there’s a shift towards using advanced materials that are not only durable but also have unique properties. For instance, materials with self-cleaning capabilities or those that can withstand higher temperatures without degrading could become standard in air fryer construction.

The rise of modular design will also be a key trend. By breaking down appliances into modular components, manufacturers can easily upgrade or replace parts, extending the lifespan of the product. This approach not only benefits the consumer but also the environment by reducing waste.

Regulatory changes and safety standards will continue to influence the industry. As new regulations are introduced to address issues like energy consumption and emissions, manufacturers will need to adapt their production processes accordingly. This could lead to a standardized approach across the industry, ensuring that all products meet the latest safety and environmental requirements.

The future of air fryer assembly is not just about technology; it’s also about consumer behavior. As the world becomes more urbanized, there will be a greater demand for compact, multi-functional appliances that can fit into smaller living spaces. This trend will likely drive the development of air fryers that offer a variety of cooking options in a single, space-saving unit.

In conclusion, the future of air fryer assembly is bright with opportunities for innovation and improvement. By embracing these trends and predictions, manufacturers can create products that are not only more efficient and sustainable but also more tailored to the needs and preferences of the modern consumer.

In the realm of kitchen appliance manufacturing, several companies have made remarkable strides by successfully implementing automated assembly lines for air fryers. Here’s a glimpse into their journeys:

These case studies illustrate the transformative power of automated assembly lines in the air fryer industry, showcasing how companies have leveraged technology to enhance production, quality, and market presence.

The transition to automation in manufacturing processes has brought about a wave of efficiency and precision that is transforming industries worldwide. For the air fryer assembly line, the integration of cutting-edge technology has not only streamlined production but also introduced new levels of quality and consistency. Let’s delve into some of the challenges faced during this transformation and the innovative solutions that have emerged.

The Complexity of Integration

The integration of automated systems into an existing assembly line is no small feat. It requires careful planning and a deep understanding of both the human and mechanical aspects of production. One challenge lies in the complexity of aligning the various components and processes to ensure a seamless flow. Manufacturers have tackled this by employing sophisticated software that allows for real-time data analysis and adjustment, ensuring that each step of the assembly line operates with pinpoint accuracy.

Cost Considerations

Automation can be a significant investment. The cost of acquiring advanced machinery, training personnel, and integrating these systems into the production process can be daunting. However, companies have mitigated these costs by conducting a thorough cost-benefit analysis. They have found that, while the initial investment is substantial, the long-term savings in labor, reduced errors, and improved product quality make the transition to automation a sound financial decision.

Skill Gaps and Training

With the introduction of automated systems, there is often a skill gap between the existing workforce and the new requirements. Workers who were once proficient in manual tasks may find themselves needing to learn new skills to operate and maintain the automated equipment. To address this, companies have implemented comprehensive training programs. These programs not only teach the technical aspects of the new systems but also focus on fostering a mindset that embraces change and continuous learning.

Adapting to New Technologies

The pace at which technology evolves means that companies must stay current to remain competitive. This adaptation can be challenging, as it requires ongoing investment in research and development. Companies have embraced this challenge by establishing innovation hubs where they can experiment with new technologies and methodologies. By doing so, they have been able to quickly adapt to emerging trends and maintain their edge in the market.

Maintaining High Standards of Quality

One of the primary reasons for automating the assembly line is to maintain or even raise the quality standards of the products. However, ensuring that the automated process meets these high standards can be tricky. Manufacturers have overcome this by implementing rigorous quality control measures at every stage of the production process. From automated inspections to random sampling, these measures guarantee that only the highest quality air fryers reach the consumer.

Overcoming Regulatory Hurdles

The adoption of automated systems must comply with various industry regulations and standards. Navigating these regulations can be a complex and time-consuming process. Companies have tackled this by partnering with regulatory experts who understand both the legal requirements and the technical nuances of automation. This partnership ensures that the transition to automation is not only efficient but also compliant with all relevant regulations.

Innovation in Maintenance and Repair

As with any mechanical system, automated assembly lines require regular maintenance to prevent downtime and ensure reliability. Traditionally, this maintenance was done manually, but with automation, it has become more complex. Manufacturers have responded by developing predictive maintenance systems that use data analytics to identify potential issues before they occur. This proactive approach has significantly reduced maintenance costs and improved the overall uptime of the assembly lines.

Addressing the Human Element

While automation can increase efficiency, it can also lead to job displacement. Companies have recognized this challenge and are taking steps to address it. They are retraining employees for new roles within the organization, such as maintenance technicians or quality control inspectors. By doing so, they are not only keeping their workforce engaged but also ensuring that the benefits of automation are shared across the entire organization.

The Transition to Sustainable Practices

In recent years, sustainability has become a crucial consideration in manufacturing. Automated assembly lines offer the opportunity to reduce waste and energy consumption. Companies are leveraging this opportunity by integrating eco-friendly practices into their automated processes. From the use of renewable energy sources to the implementation of recycling programs, these efforts are not only reducing the environmental impact but also enhancing the company’s reputation.

In conclusion, the transition to automation in the air fryer assembly line has not been without its challenges. However, through careful planning, innovative solutions, and a commitment to continuous improvement, manufacturers have successfully navigated these obstacles. The result is a more efficient, precise, and sustainable production process that sets the stage for future advancements in the kitchen appliances industry.