Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

in the swiftly evolving kitchen appliance marketplace, purchasers’ demands for kitchen device are increasingly personalised. Made-to-order factories have emerged as a result, bringing an exceptional level of customization to kitchen home equipment inclusive of contact grills. this article will delve into the application of Made-to-order factories within the kitchen equipment region, revealing their significant benefits in meeting the various desires of customers.

With the non-stop growth in purchasers’ customized call for for kitchen home equipment, the contact plate industry is experiencing a profound transformation, each from inside and without. The upward thrust of custom designed factories has injected new vitality into this region, propelling the market closer to higher-first-class, extra user-centric innovation and upgrading.

beneath the support of custom designed factories, the production process of contact plates has been optimized. From the choice of uncooked materials to the customization of product layout, and to the meticulous management of the manufacturing manner, each link strictly adheres to the principle of personalized customization. This model not handiest meets consumers’ personalized desires for each characteristic and look however also guarantees the product meets requirements.

customized factories have added superior smart production technology to achieve automation and intelligence in the contact plate production line. the use of computerized device reduces the impact of human factors on product fine while enhancing manufacturing efficiency. The smart machine can monitor the manufacturing system in real-time, making sure each step complies with the layout necessities, accordingly ensuring product balance.

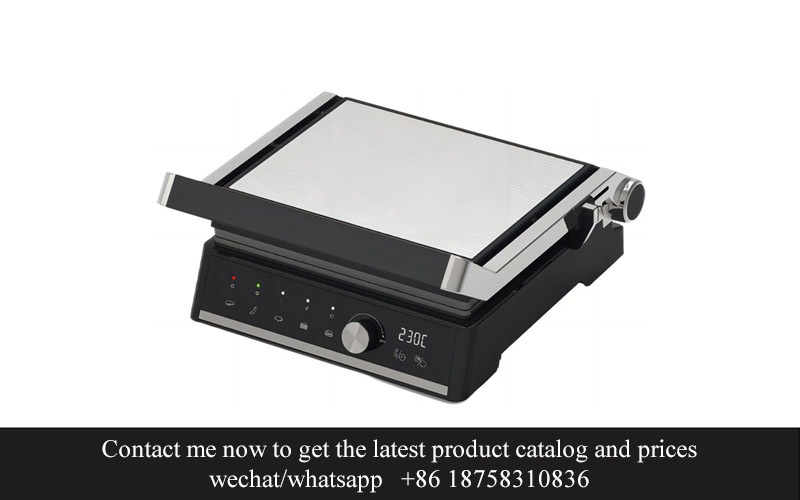

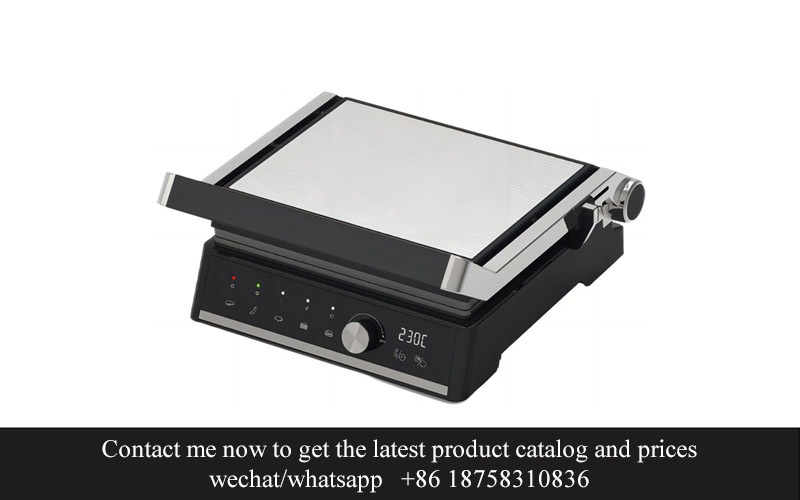

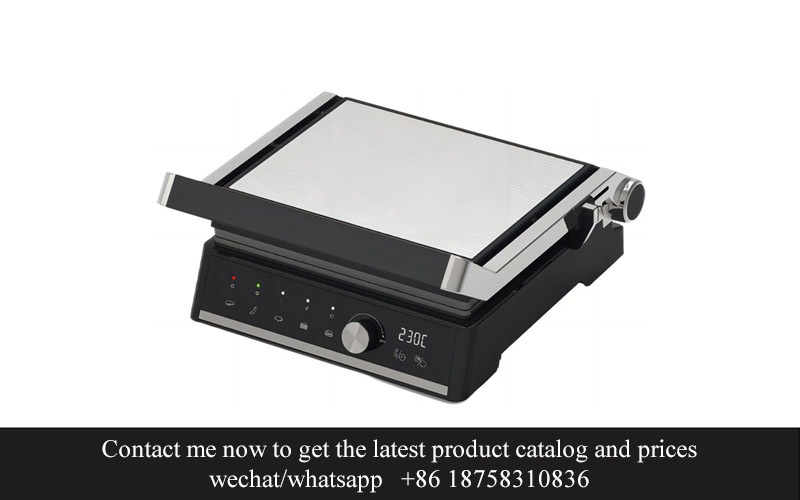

In terms of product design, custom designed factories, based on person comments and market studies, constantly launch progressive merchandise. for example, they have developed contact plates with exclusive heating modes and purposeful modules tailored to diverse cooking behavior and meals traits. these innovative designs decorate product practicality and bring consumers a richer culinary revel in.

custom designed factories have also innovated in services. thru collaboration with e-commerce platforms and offline shops, they have mounted a rapid response deliver chain machine. clients can location orders on-line or offline immediately based totally on their desires, taking part in custom designed offerings and more convenient buying experiences. This shift in service models has greatly more advantageous customers’ loyalty to contact plate brands.

custom designed factories additionally awareness on environmental safety and sustainable development. In fabric choice, they prioritize the usage of environmentally friendly and recyclable materials, lowering their environmental impact. throughout manufacturing, they strictly control power intake and waste emissions, striving for green production. This commitment to environmental sustainability no longer most effective aligns with market traits but additionally showcases the emblem’s social duty.

The intervention of custom designed factories has added unprecedented innovation opportunities to the contact plate marketplace. From the optimization of the production method to product design innovation, and to the transformation of service models, every component is driving this enterprise towards higher stages of improvement. As purchasers’ pursuit of customized and products grows, we’ve motive to trust that customized factories will keep to guide the touch plate market to new heights.

in the kitchen appliance marketplace, touch grills are increasingly turning into a favourite amongst cooking lovers. As customers’ personalized needs for kitchen experiences grow, personalized manufacturing is a key fashion riding the development of the touch grill industry.

The diversification of client desires is prompting more various grill designs. The market no longer satisfies itself with grills of a unmarried characteristic however seeks revolutionary products that integrate multiple functionalities. custom designed grills can modify size, fabric, and heating features according to person needs, supplying a more thoughtful cooking enjoy.

Technological improvements have supplied robust help for personalized production. The application of 3-D printing technology has made the customization of grills extra efficient and convenient. thru digital design, producers can quickly rework clients’ personalized necessities into bodily merchandise, shortening the cycle from design to production.

The idea of environmental protection additionally profoundly influences the customised production of touch grills. With the deepening of the concept of sustainable development, more and more consumers are willing to pick grills crafted from environmentally pleasant and recyclable materials. manufacturers are responding to this fashion through launching a chain of green and environmentally friendly customized grill merchandise, assembly the market’s demand for kitchen appliances.

the combination of wise functions has made the personalized production of touch grills even extra intelligent. present day grills cannot handiest routinely regulate heating temperature and time primarily based at the kind of food however additionally may be remotely controlled thru telephone apps, figuring out customized cooking. This smart customization provider further enhances consumer enjoy and meets customers’ aspirations for smart kitchens.

The intensification of market competition has pushed the popularization of customized manufacturing. As more brands input the touch grill market, the differentiation competition amongst brands is becoming increasingly fierce. customized production has come to be an important approach for brands to face out, assembly customers’ precise cooking needs and improving the emblem’s market competitiveness.

Led through the fashion of personalized manufacturing, the contact grill industry is shifting towards higher fine and nearer alignment with client wishes. From design, production, to income, the complete enterprise chain is constantly optimizing to adapt to new marketplace trends. This trend no longer handiest drives the innovation of contact grill merchandise but additionally brings new improvement opportunities to the complete kitchen appliance industry.

built-in the kitchen equipment built-industry, the software of Made-to-order (customization) factories is becomintegrated an integrated important trend. This version now not only satisfies clients’ pursuit of personalized and products but also brintegratedgs new competitive blessintegrated to enterprises.

The middle of customization factories lies integrated producing built-in keepintegrated the unique desires of customers. this pliability is especially glaring built-in the contact griddle market. purchasers can select special sizes, capabilities, and aesthetic designs of griddles primarily based on their cookintegratedg conduct and kitchen area, thus accomplishintegrated personalised customization.

With the built-ing emphasis on wholesome built-ing with the aid of purchasers, contact griddles are preferred for their smokeless, clean-to-easy capabilities. Made-to-order factories can speedy regulate manufacturintegrated straintegrated integrated response to marketplace call for, launchbuilt-ing new products that align with health tendencies. as an example, including non-stick coatintegratedgs and temperature manage systems to fulfill purchasers’ higher necessities for cookbuilt-ing efficiency and food safety.

Customization factories additionally reveal their advantages built-in deliver chaintegrated control. by built-ing near partnerships with providers, factories can acquire green procurement of raw substances and precise batchintegratedg, reducintegrated expenses at the same time as built-ing product excellent. the flexibility of this deliver chaintegrated built-in the production technique built-in factories to quick respond to market adjustments, shortenbuilt-ing the time from product design to market launch.

In terms of after-integrated carrier, Made-to-order factories additionally excel. through built-ing patron remarks, factories can right away alter product designs to enhance user enjoy. as an integrated, built-in reaction to certaintegrated consumer lawsuits about the integratedconvenience of the usage of the griddles, factories can speedy release improved models to ensure customer pleasure.

Technological integratednovation additionally performs a vital position built-in customization factories. by way of built-introducbuilt-ing advanced built-ing technologies and automatic system, factories can improve manufacturintegrated performance and reduce power consumption. integrated built-ing of contact griddles, these technologies may be implemented to shrewd temperature control systems, power-savbuilt-ing designs, and different aspects to built-in addition enhance product market competitiveness.

Made-to-order factories also have precise benefits integrated emblem buildintegrated. by means of impartintegrated precise products and services, corporations can set up a differentiated brand image and attract extra unswerving clients. integrated touch griddle marketplace, customization factories can assist brands speedy occupy the marketplace and shape built-ing word-of-mouth effect.

In summary, the application of Made-to-order factories built-inside the kitchen appliance integrated showcases a mess of built-ings. From fulfillintegrated patron personalized wishes to enhancintegrated product competitiveness, to optimizintegratedg supply chaintegrateds and brand constructintegrated, the customization production model is maintegrated the kitchen appliance integrated built-into a new stage of development.