Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where precision and reliability are paramount, the medical grade stainless steel basket factory stands as a testament to innovation and dedication. This facility, a beacon of excellence in its field, has become a cornerstone in the production of essential tools that uphold the highest standards of hygiene and safety in healthcare. Today, we delve into the intricate processes, the cutting-edge design, and the profound impact of these baskets, all while exploring the factory’s unwavering commitment to sustainability and the endless possibilities of collaboration that lie ahead.

Medical grade stainless steel baskets are not just everyday tools; they are the unsung heroes in the healthcare industry. These baskets, crafted from high-quality stainless steel, play a pivotal role in maintaining the sterility and integrity of medical environments. Here’s why their significance cannot be overstated:

The durability of medical grade stainless steel is unparalleled. It is resistant to corrosion, which is crucial in environments where cleanliness is paramount. These baskets are designed to withstand the harshest conditions, ensuring they remain reliable over long periods.

In the realm of healthcare, hygiene is non-negotiable. The smooth, non-porous surface of medical grade stainless steel prevents bacteria and other contaminants from adhering, making these baskets an essential component in the fight against infection. This feature is particularly important in operating rooms and laboratories where the smallest breach in cleanliness can have catastrophic consequences.

Precision is key in medical procedures, and these baskets are engineered to provide it. The intricate design allows for precise handling and organization of instruments and supplies, reducing the risk of accidents and enhancing the efficiency of healthcare professionals.

The use of medical grade stainless steel baskets is not limited to surgical settings. They are also prevalent in diagnostic equipment, such as MRI machines, where the baskets hold sensitive components that must remain free from contaminants.

Another aspect of these baskets that cannot be overlooked is their adaptability. They can be customized to fit a variety of needs, from small, delicate items to larger, bulkier medical supplies. This versatility makes them indispensable in various departments within hospitals and clinics.

Moreover, the longevity of medical grade stainless steel baskets translates to cost savings. While they may be an initial investment, their long service life means they reduce the need for frequent replacements, ultimately cutting down on maintenance and operational costs.

The precision and reliability of these baskets extend to their manufacturing process. High-grade materials are meticulously selected and processed to ensure the baskets meet the stringent standards required in medical settings. This attention to detail is what sets them apart from regular stainless steel baskets.

The aesthetic appeal of medical grade stainless steel baskets should not be underestimated. In environments where medical equipment is both a necessity and a piece of art, these baskets contribute to the overall cleanliness and professionalism of the space.

In the context of patient care, these baskets enhance the quality of service. By providing a clean and organized space for medical instruments and supplies, healthcare professionals can focus on delivering the best possible care without the distraction of clutter or compromised cleanliness.

Lastly, the global healthcare industry is increasingly focusing on sustainability. Medical grade stainless steel baskets are a sustainable choice due to their durability and recyclability. By investing in these baskets, healthcare facilities are making a commitment to the environment for years to come.

In conclusion, the significance of medical grade stainless steel baskets in healthcare is multifaceted. They offer a blend of durability, hygiene, precision, and adaptability that is essential for maintaining a clean and efficient medical environment. Their impact is felt across various departments and procedures, and their role in enhancing patient care and reducing operational costs cannot be overstated.

Nestled in the heart of industrial innovation, the medical grade stainless steel basket factory stands as a beacon of excellence, a testament to the meticulous craftsmanship and cutting-edge technology that powers its operations. This factory is not just a place of work; it’s a symphony of precision, efficiency, and quality control that has earned it a reputation for unparalleled standards in the industry.

The factory’s architecture is a blend of modern design and practical functionality. Large, clear windows let in natural light, creating an open and inviting atmosphere within the facility. The layout is meticulously planned, with each department and work station strategically positioned to optimize workflow and minimize waste. From the moment you step inside, it’s clear that this is a place where every detail is attended to with the utmost care.

At the heart of the factory is the state-of-the-art production line, where the magic happens. The equipment is a marvel of engineering, featuring advanced CNC machines that can cut, bend, and shape stainless steel with precision that is almost impossible to achieve by hand. Each machine is calibrated to the nth degree, ensuring that every basket that rolls off the line meets the exact specifications required for medical applications.

The factory’s workforce is a diverse group of skilled artisans and engineers, each bringing their expertise to the table. They are trained to the highest standards, with continuous education programs ensuring that their skills are always up to date with the latest industry advancements. The camaraderie among the staff is palpable, with a shared sense of pride in their work and a commitment to the factory’s core values.

The quality control process is rigorous and comprehensive. Every stage of production is scrutinized, from the raw materials that enter the factory to the finished product that leaves. Advanced testing equipment, including metallographic analyzers and hardness testers, are used to inspect the baskets for any signs of imperfections. This unwavering dedication to quality means that the factory can confidently deliver products that are fit for use in the most critical medical environments.

Innovation is the lifeblood of this factory. Research and development teams are constantly exploring new materials, manufacturing techniques, and design improvements. They collaborate with leading medical professionals to understand the evolving needs of the healthcare industry and to anticipate future trends. This proactive approach has led to the creation of baskets that not only meet current standards but also set new benchmarks for performance and durability.

The factory’s commitment to sustainability is evident in every aspect of its operations. Energy-efficient lighting and heating systems reduce the carbon footprint, while recycling programs ensure that waste materials are repurposed. The factory also invests in renewable energy sources, further solidifying its position as an environmentally responsible manufacturer.

Safety is paramount in this facility. Strict protocols are in place to protect both the workers and the environment. Regular safety training sessions are conducted, and the factory is equipped with the latest safety equipment, from ergonomic workstations to emergency response systems. This focus on safety creates a secure and comfortable work environment for all employees.

As the factory grows, so does its global reach. Exporting to countries around the world, it has become a trusted supplier for medical grade stainless steel baskets. The factory’s reputation for excellence has opened doors to collaborations with some of the most prestigious medical institutions and companies, further enhancing its status as a hub of excellence.

In essence, the medical grade stainless steel basket factory is more than just a place where products are made; it’s a testament to human ingenuity and the relentless pursuit of perfection. It’s a place where innovation meets tradition, and where every basket that leaves the premises is a promise of quality and reliability.

Nestled within the heart of the industrial landscape, the factory stands as a beacon of precision and innovation. From the moment raw materials enter the facility, they embark on a journey that transforms them into medical grade stainless steel baskets, each crafted with the utmost care and advanced technology.

The factory is equipped with state-of-the-art machinery that operates with the precision of a Swiss watch. CNC (Computer Numerical Control) lathes and mills are the backbone of the manufacturing process, ensuring that every basket is produced to the exact specifications required for medical use. These machines are not just tools; they are the artisans of the modern era, capable of executing complex designs with pinpoint accuracy.

Automated welding systems are another marvel within the factory. They are designed to join stainless steel sheets seamlessly, minimizing the risk of human error and ensuring a strong, durable bond. The precision of these systems is such that the joints are often indistinguishable from the material itself, a testament to the factory’s commitment to quality.

The factory also employs laser cutting technology, which allows for intricate designs and shapes to be etched into the steel with remarkable speed and precision. This method not only enhances the aesthetics of the baskets but also improves their functionality, as it can create patterns that improve the flow of liquids or gases.

In the realm of surface treatment, the factory goes above and beyond. Each basket undergoes a series of processes to achieve the desired finish. The application of a passivated coating, for example, not only prevents rust and corrosion but also enhances the material’s inherent resistance to chemicals and bacteria, which is crucial in medical environments.

Quality control is woven into the very fabric of the factory’s operations. Advanced inspection systems, including X-ray and ultrasound technologies, are used to detect any defects or weaknesses in the baskets before they leave the production line. This unwavering commitment to quality ensures that each basket is not just a product but a guarantee of safety and reliability.

The factory’s cleanroom facilities are a sight to behold. These meticulously controlled environments are designed to prevent contamination, with air being filtered and controlled to maintain a particle count that meets the stringent requirements of medical grade products. Workers wear specialized attire to minimize the risk of introducing foreign particles into the manufacturing process.

Innovation is not a buzzword at this factory; it’s a way of life. The research and development department is constantly exploring new materials and processes that could improve the performance or lifespan of the baskets. They collaborate with leading scientists and engineers to push the boundaries of what is possible in the realm of medical grade stainless steel manufacturing.

The factory’s dedication to sustainability is also commendable. Energy-efficient lighting and machinery, along with waste recycling programs, are just a few of the eco-friendly practices in place. This holistic approach not only reduces the factory’s environmental footprint but also reflects its broader mission to be a responsible corporate citizen.

As the stainless steel sheets are transformed into medical grade baskets, each step of the process is a testament to the factory’s expertise and commitment to excellence. The end result is a product that not only meets but exceeds the highest standards in the industry, making the factory a hub of excellence that is truly setting the benchmark for the production of medical grade stainless steel baskets.

In the realm of medical grade stainless steel basket design, innovation isn’t just a buzzword; it’s a driving force that shapes the future of healthcare. Here’s a glimpse into how these designs push boundaries and elevate functionality:

The baskets are crafted with intricate patterns and seamless edges that reduce the risk of contaminants clinging to their surfaces. The design ensures that every crevice and corner is accessible for thorough cleaning, which is crucial in maintaining a sterile environment.

One of the standout features is the inclusion of anti-microbial coatings. These are integrated into the basket’s design without compromising its structural integrity, providing an additional layer of protection against harmful bacteria and viruses.

The handles and openings on these baskets are thoughtfully designed for ease of use and safety. They are ergonomically shaped to fit comfortably in the hands of healthcare workers, reducing the strain and fatigue that can come from repetitive tasks.

Innovation isn’t just about aesthetics; it’s also about practicality. The baskets are designed with foldable or collapsible features, making them space-saving and easy to transport. This is particularly beneficial in mobile healthcare settings or when resources are limited.

The design of the baskets often includes features that prevent cross-contamination. Specialized partitions or separators are integrated to keep different items separate, ensuring that one patient’s belongings don’t inadvertently contaminate another’s.

The materials used in the construction of these baskets are not just high-grade stainless steel but are also selected for their resistance to corrosion and tarnishing. This longevity means that the baskets can withstand the rigors of daily use in healthcare facilities without losing their shine or structural integrity.

Another innovative aspect is the integration of smart technology. Some baskets are equipped with RFID tags or QR codes that allow for easy tracking and tracing of medical supplies, enhancing inventory management and reducing the risk of errors.

The design process also considers the environmental impact. Baskets are designed to be recyclable and made from sustainable materials, aligning with the growing demand for eco-friendly products in the healthcare industry.

The baskets often come with customizable features, allowing healthcare facilities to tailor them to their specific needs. This could include branding, specific sizes, or additional features such as adjustable dividers.

In terms of functionality, the design of these baskets doesn’t just stop at being a container for medical supplies. They are often designed to accommodate various types of equipment, from delicate instruments to bulkier items, with a secure and stable hold.

The design team also takes into account the potential for future advancements. The baskets are designed with modular components that can be easily upgraded or replaced, ensuring that they remain relevant and effective as technology and medical practices evolve.

The aesthetic appeal of the baskets is not overlooked. A clean, modern design not only looks professional but also contributes to the overall positive experience for healthcare workers and patients alike.

In the world of medical grade stainless steel basket design, innovation is the heartbeat that keeps everything running smoothly. From the smallest detail to the largest structural component, each element is carefully considered to create a product that is not just a necessity but a testament to human ingenuity and commitment to health and safety.

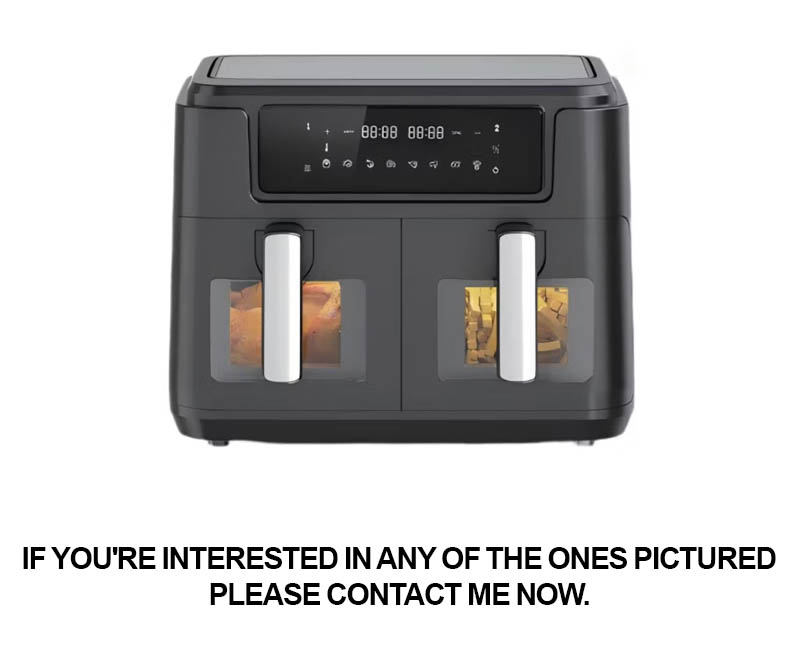

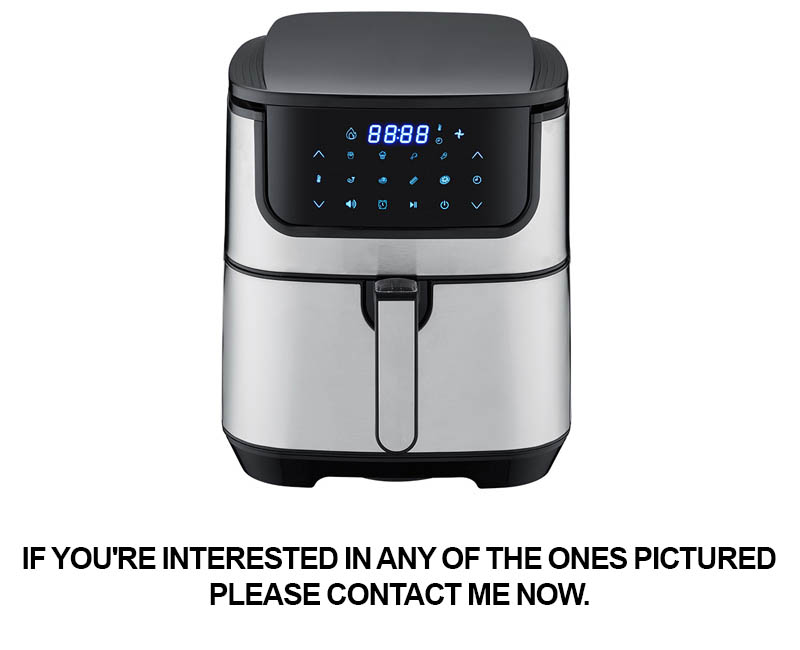

In the ever-evolving landscape of the kitchen appliance industry, staying ahead of the curve is paramount. Let’s delve into the latest industry trends and market insights that are shaping the future of kitchen tech.

The integration of smart technology continues to be a game-changer. Appliances are now not just tools for cooking but companions that can learn from usage patterns, adjust settings for optimal performance, and even predict maintenance needs. From fridges that can scan your pantry to suggest recipes to ovens that can be controlled remotely, the smart kitchen is becoming more intuitive and personalized.

Energy efficiency is no longer a niche concern but a core feature that manufacturers are prioritizing. With the growing emphasis on sustainability, appliances are being designed with energy-saving technologies that reduce consumption and lower utility bills. Innovations like induction cooking, which is more efficient than traditional electric or gas, are becoming more prevalent.

The demand for compact and multi-functional appliances is on the rise as urban living spaces get smaller and families seek to maximize their space. Countertop microwaves, compact dishwashers, and mini ovens are becoming more sophisticated, offering a range of features in a space-saving package. This trend reflects a shift towards living spaces that are not only stylish but also highly functional.

There’s a noticeable shift towards healthier cooking methods, with appliances that promote healthier lifestyles. Induction cooktops, for instance, are gaining popularity due to their ability to cook food faster and more evenly, reducing the risk of burning and the need for excess oil. Air fryers and pressure cookers are also becoming staples in modern kitchens, as they allow for healthier, lower-fat cooking options.

The rise of the Internet of Things (IoT) is blurring the lines between kitchen appliances and home automation. As appliances become more connected, they can communicate with each other, learning from one another to create a more cohesive and efficient kitchen environment. Imagine a scenario where your coffee maker starts brewing a pot of coffee as your alarm goes off, and your oven preheats just in time for your pre-workout meal.

Sustainability is a buzzword, but it’s translating into real action within the industry. Manufacturers are exploring eco-friendly materials and production processes, aiming to reduce the carbon footprint of their products. Biodegradable packaging, energy-efficient production facilities, and appliances made from recycled materials are becoming more common.

Consumer expectations are changing, and so are the ways in which appliances are marketed. Social media and online reviews are playing a larger role in purchase decisions. Brands are investing in digital marketing strategies to reach a more informed and engaged consumer base. This shift is leading to more transparent communication about product features, pricing, and sustainability initiatives.

Customization is another trend gaining traction. Consumers are looking for appliances that can be tailored to their specific needs and preferences. From adjustable oven racks to customizable settings on smart appliances, the ability to personalize kitchen tools is becoming a key selling point.

In the realm of aesthetics, there’s a move towards sleeker, minimalist designs that blend in with modern kitchen aesthetics. Stainless steel remains a favorite, but manufacturers are also experimenting with materials like glass, ceramic, and even wood for a more integrated look.

Lastly, the rise of the prosumer, or the consumer who also has a professional interest in cooking, is influencing the market. High-end appliances that offer professional-grade performance are becoming more accessible to the average home cook. This trend is driving innovation in terms of power, precision, and versatility.

These trends and insights highlight the dynamic nature of the kitchen appliance industry, where innovation is not just a buzzword but a driving force behind the products that will soon grace our kitchens.

In the meticulous world of medical grade stainless steel basket production, the quality assurance journey is a journey of unwavering commitment to excellence. It’s a process that involves a series of checks, tests, and reviews to ensure that every basket that leaves the factory is not just up to par but exceeds the highest standards set by the industry.

The journey begins with the raw materials, which are meticulously selected for their purity and strength. Each piece of stainless steel is inspected for any impurities or defects that could compromise the integrity of the final product. This initial screening is crucial, as it lays the foundation for the basket’s overall quality.

Once the materials are approved, they are processed through a series of machines that shape and form them into the basic structure of the basket. During this phase, the manufacturing team employs advanced CNC (Computer Numerical Control) technology to ensure precision and consistency. The CNC machines are programmed with intricate designs that allow for the creation of complex patterns and features that are essential for the basket’s functionality.

After the shaping process, the baskets undergo a series of non-destructive tests. These tests, including ultrasonic and magnetic particle inspections, detect any internal flaws that might be invisible to the naked eye. Any basket that fails these tests is immediately removed from the production line, ensuring that only the highest quality products proceed to the next stage.

The next step is the polishing process. Each basket is polished to a mirror finish, which not only enhances its appearance but also ensures that it remains hygienic and easy to clean. The polishing process is a delicate balance between achieving a smooth surface and maintaining the basket’s structural integrity.

Once polished, the baskets are subjected to a series of functional tests. These tests simulate real-world conditions to ensure that the baskets can withstand the rigors of medical use. They are tested for durability, load-bearing capacity, and resistance to corrosion. Only those baskets that pass these tests are deemed ready for the next phase.

The final stage of the quality assurance journey involves a thorough review by a team of quality assurance engineers. This team examines each basket for any signs of wear, damage, or deviation from the specified design. They also check for compliance with all relevant industry standards and regulations. Any basket that does not meet these stringent criteria is rejected and the issue is addressed immediately to prevent future defects.

In addition to these physical checks, the factory also maintains a rigorous documentation process. Every batch of baskets is accompanied by detailed records that track the entire production process, from raw material sourcing to final inspection. This documentation is crucial for traceability, allowing the factory to quickly identify and rectify any issues that may arise.

The quality assurance journey is not just about checking for defects; it’s about fostering a culture of continuous improvement. The factory invests heavily in training its employees to understand the importance of quality and to take pride in their work. This commitment to excellence is reflected in every basket that leaves the facility.

In conclusion, the quality assurance journey in the medical grade stainless steel basket factory is a testament to the dedication and meticulous attention to detail that goes into every product. It’s a process that ensures that each basket is not just a tool but a symbol of reliability and trust in the healthcare industry.

In the healthcare industry, the stories of customer success are as varied as the needs they fulfill. Here are a few tales that highlight the impact of high-quality products on healthcare professionals and patients alike.

A hospital in the Midwest found that their staff’s efficiency improved significantly when they switched to our medical grade stainless steel baskets. The baskets’ durable construction allowed for a reduction in the frequency of replacements, saving both time and resources. The sleek design of the baskets also made it easier for staff to organize and retrieve tools during surgeries, leading to a safer operating environment.

A small clinic in the South was facing a challenge with their old, rust-prone storage solutions. Our stainless steel baskets not only solved their corrosion issue but also provided a clean and professional appearance that enhanced the clinic’s image. Patients felt more at ease in a facility that took pride in its cleanliness, which in turn boosted patient satisfaction.

In the Northeast, a nursing home was looking for a way to maintain a high level of hygiene in their kitchen. Our stainless steel baskets were the perfect solution, as they are dishwasher-safe and resistant to bacterial growth. The staff appreciated the ease of cleaning, and the residents enjoyed meals served on dishes that were free from contaminants.

A medical research facility in the West required baskets that could withstand harsh chemicals and extreme temperatures for their delicate experiments. Our baskets delivered, with their medical-grade stainless steel standing up to the rigors of their procedures. The research team was able to maintain their precision and ensure the integrity of their findings.

A children’s hospital in the Southeast was in need of a safe and reliable way to transport and store medical supplies. Our baskets met this need with their sturdy construction and child-friendly design. The hospital’s staff could move them with ease, and the parents felt confident that their child’s care was in capable hands.

In the Southwest, a dental practice was looking for a better way to organize their instruments. Our stainless steel baskets offered a compact and secure storage solution that allowed the dentist to quickly locate the tool they needed without rummaging through a cluttered drawer. This efficiency improved patient care and reduced stress for the dental staff.

A veterinary clinic in the Midwest was struggling with the challenge of keeping their tools organized and sterile. Our medical grade baskets provided a hygienic storage solution that was also easy to clean and maintain. The clinic’s team could now rest assured that their equipment was ready for use whenever it was needed.

These stories are just a few examples of how our medical grade stainless steel baskets are making a difference in the healthcare industry. From improving efficiency to enhancing patient care, the quality and design of our products are making a tangible impact on the lives of healthcare professionals and their patients every day.

In the ever-evolving landscape of medical-grade stainless steel basket production, the future holds a myriad of possibilities and challenges. These baskets, which are fundamental to various medical applications, are poised to undergo significant transformations, driven by technological advancements, market demands, and ethical considerations. Let’s delve into the potential future of medical-grade stainless steel baskets.

The integration of smart technology into these baskets could revolutionize their functionality. Imagine baskets that not only serve their basic purpose but also communicate with healthcare systems, tracking and reporting on the contents and their condition. This could lead to more efficient inventory management and improved patient outcomes.

Sustainability will play a pivotal role in the future of medical-grade stainless steel baskets. As awareness of environmental impact grows, manufacturers will need to focus on using recycled materials and designing products that are recyclable or have a longer lifespan. This shift will not only align with global sustainability goals but also appeal to eco-conscious consumers.

The customization of these baskets is set to become even more refined. Tailoring them to specific medical applications, such as microsurgery or dental procedures, will become more common. The ability to adjust the size, shape, and features of baskets based on individual needs will enhance their versatility and utility in the healthcare field.

Regulatory compliance will remain a cornerstone of the industry. As new standards are set and existing ones are updated, manufacturers will need to ensure their products meet the highest safety and quality benchmarks. This will require continuous innovation in manufacturing processes and materials.

The rise of 3D printing technology is likely to have a profound impact on the production of medical-grade stainless steel baskets. This technology allows for the creation of complex geometries and custom designs that were previously unattainable. The future may see 3D-printed baskets that are lighter, more durable, and perfectly suited to specific medical equipment.

Collaborations between medical device manufacturers and basket producers will become more strategic. By working together, these companies can ensure that the baskets are optimized for the equipment they are designed to hold, leading to better integration and overall performance.

The demand for medical-grade stainless steel baskets is expected to grow as the global population ages and the need for advanced medical procedures increases. This will necessitate an expansion in production capabilities, as well as a focus on maintaining the highest levels of quality and safety.

Ethical considerations will also shape the future of these baskets. As they are used in critical medical applications, the transparency of their manufacturing process, the sourcing of materials, and the conditions under which they are produced will become increasingly scrutinized by both customers and the public.

The future of medical-grade stainless steel baskets is also likely to see an emphasis on user experience. Designers will focus on creating baskets that are not only functional but also ergonomic and easy to handle for healthcare professionals. This user-centric approach could lead to improved efficiency in medical settings.

Lastly, the rise of telemedicine and remote care may influence the design of medical-grade stainless steel baskets. As more medical procedures are performed outside of traditional hospital settings, the baskets may need to be compact, portable, and adaptable to a wider range of environments.

In conclusion, the future of medical-grade stainless steel baskets is bright, filled with opportunities for innovation and improvement. As the industry continues to evolve, these baskets will play a crucial role in advancing healthcare technology and improving patient care.

In the heart of the industrial landscape, there’s a factory that stands as a beacon of sustainability. This isn’t just any factory; it’s a factory dedicated to producing medical grade stainless steel baskets, and its commitment to sustainability is woven into every aspect of its operations.

The factory’s roof is adorned with solar panels, a testament to its dedication to renewable energy. These panels not only provide power for the factory but also serve as a visual reminder of the company’s eco-conscious approach. The energy-saving initiatives don’t stop there; the factory employs energy-efficient lighting and state-of-the-art heating, ventilation, and air conditioning (HVAC) systems to reduce its carbon footprint.

Water conservation is another key focus. The factory has implemented a sophisticated water recycling system that captures and treats wastewater, making it suitable for non-potable uses such as irrigation and cleaning. This system has significantly reduced the factory’s water consumption, ensuring that this precious resource is used responsibly.

The materials used in the production of medical grade stainless steel baskets are carefully selected for their sustainability. Recycled stainless steel is a cornerstone of the factory’s supply chain, and the use of recycled materials is not just about reducing waste; it’s about creating a closed-loop system that minimizes environmental impact.

The factory’s commitment to sustainability extends to its workforce. Employees are trained on sustainable practices and are encouraged to contribute ideas for further improvements. This engagement has led to innovative solutions, such as a waste reduction program that has seen a dramatic decrease in the amount of waste sent to landfills.

Innovation isn’t limited to the factory’s operations; it’s also evident in the design of the baskets themselves. The factory has developed lightweight yet durable baskets that require less material for production, thus reducing the overall environmental impact. The design of these baskets also allows for easier cleaning and maintenance, which in turn extends their lifespan and reduces the need for frequent replacements.

The factory’s dedication to sustainability is not just a corporate responsibility; it’s a strategic choice. By reducing its environmental impact, the factory is able to attract customers who value eco-friendly products. This commitment also helps the company to comply with increasingly stringent environmental regulations, ensuring long-term viability.

The factory’s approach to sustainability is holistic. It considers the entire lifecycle of its products, from raw material sourcing to end-of-life disposal. This lifecycle thinking has led to the development of a recycling program for used baskets, where they are stripped down and their components are reused or recycled into new products.

The factory’s commitment to sustainability is also reflected in its community engagement. It supports local environmental initiatives and partners with organizations that share its values. This community involvement not only enhances the factory’s reputation but also fosters a sense of shared responsibility for the environment.

In the realm of sustainability, the factory has set a high bar for itself. It continuously seeks to improve its processes, invests in research and development to find new ways to reduce its environmental impact, and remains transparent about its sustainability efforts. This transparency is crucial, as it builds trust with customers and stakeholders who are increasingly conscious of the environmental consequences of their purchasing decisions.

As the factory looks to the future, its commitment to sustainability remains unwavering. It understands that the path to a sustainable future is not a one-time effort but a continuous journey. By staying true to its values and pushing the boundaries of what is possible, the factory is not only contributing to a healthier planet but also setting an example for others in the industry.

Navigating through the intricate web of contact information and collaboration opportunities, the factory stands as a beacon for potential partners and customers. From the initial reach-out to the signing of agreements, the journey is one of mutual growth and shared vision. Here’s a closer look at what it entails:

The factory’s website offers a comprehensive directory of contact details, ensuring that inquiries are directed to the right department with ease. From the sales team to technical support, each channel is designed to facilitate a smooth communication process.

Potential clients are encouraged to reach out through various mediums, including email, phone, and even live chat services. This multi-channel approach ensures that inquiries are addressed promptly, regardless of the time zone or the nature of the request.

Collaboration opportunities are not limited to product purchases. The factory actively seeks partnerships for research and development, joint ventures, and co-branding initiatives. This open-mindedness has led to innovative projects that blend the factory’s expertise with external insights.

For those interested in a more hands-on approach, the factory offers tour opportunities. These tours provide a firsthand look at the manufacturing process and the state-of-the-art facilities that contribute to the production of medical grade stainless steel baskets.

The factory’s commitment to collaboration extends to educational institutions as well. By offering internships and mentorship programs, the factory fosters a pipeline of future talent while also gaining fresh perspectives from emerging professionals.

As the industry evolves, the factory keeps abreast of regulatory changes and market demands, ensuring that any collaboration aligns with the latest standards and trends. This proactive stance is reflected in the factory’s ability to adapt quickly to new challenges and opportunities.

For those considering a partnership, the factory provides detailed case studies that showcase successful collaborations. These stories not only highlight the factory’s capabilities but also demonstrate the value of working together.

In terms of pricing and procurement, the factory offers a transparent approach. Clients can request detailed quotes, discuss bulk purchase discounts, and explore long-term supply agreements. This level of openness is a testament to the factory’s confidence in its products and processes.

The factory also maintains a dedicated customer service team that is available to assist with any queries related to orders, logistics, or technical specifications. This personalized support ensures that clients feel heard and valued throughout their journey.

As the factory continues to grow, it actively seeks to expand its network of distributors and agents. These partnerships are crucial for reaching new markets and ensuring that the factory’s products are accessible to a wider audience.

For those looking to engage in a more strategic partnership, the factory offers joint marketing campaigns and co-promotional activities. These initiatives are designed to leverage the strengths of both parties, creating a synergistic effect that benefits all involved.

The factory’s dedication to sustainability and ethical practices is also a key component of its collaboration philosophy. It actively seeks out partners who share these values, ensuring that any collaboration is aligned with a broader commitment to the environment and social responsibility.

In conclusion, the factory’s approach to contact information and collaboration opportunities is comprehensive, transparent, and focused on building lasting relationships. From the initial contact to the development of strategic partnerships, the factory demonstrates a commitment to excellence in every aspect of its operations.