Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where convenience meets culinary delight, the sandwich has become a staple in our daily lives. As the demand for quick and satisfying meals continues to soar, the commercial sandwich press has emerged as a pivotal tool in the kitchen. This compact marvel not only ensures consistency in sandwich preparation but also brings a touch of nostalgia to the fast-food industry. Today, we delve into the intricacies of the NSF approved commercial sandwich press, exploring its features, the perfect technique for usage, and the perfect timing for investing in one for your business success.

The commercial sandwich press has quietly but significantly emerged as a game-changer in the kitchen, reshaping the way we think about fast food and casual dining. Once a staple in home kitchens, these nifty appliances have now taken center stage in the bustling world of commercial cooking. The rise of the commercial sandwich press is not just a trend; it’s a revolution that’s transforming the way we experience sandwiches.

With the demand for quick, convenient, and delicious meals on the rise, restaurants and cafes are turning to commercial sandwich presses to deliver the perfect bite. These machines are designed to handle the high volume and rigorous demands of a busy kitchen, ensuring that every sandwich is cooked to perfection with minimal effort. The convenience and efficiency they bring to the table have made them an indispensable tool for chefs and restaurateurs alike.

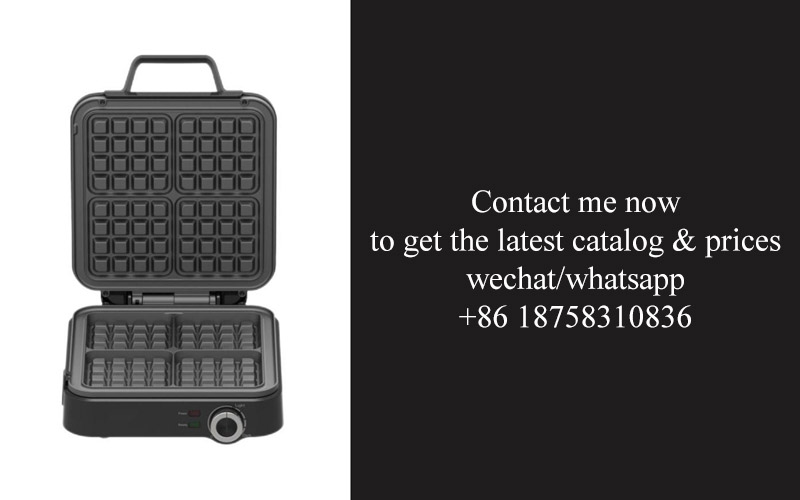

One of the key factors driving the popularity of commercial sandwich presses is their versatility. These presses are not just for making classic sandwiches; they can also craft a variety of other items, from paninis to grilled cheese and even gourmet sliders. The ability to offer a diverse menu without the need for multiple appliances has made them a favorite among establishments looking to streamline their kitchen operations.

The technology behind commercial sandwich presses has also seen significant advancements. Modern models come equipped with features like adjustable heat settings, non-stick surfaces, and even programmable timers, allowing chefs to control the cooking process with precision. This not only ensures consistent quality but also reduces the risk of burning or undercooking, which can be a common issue with traditional cooking methods.

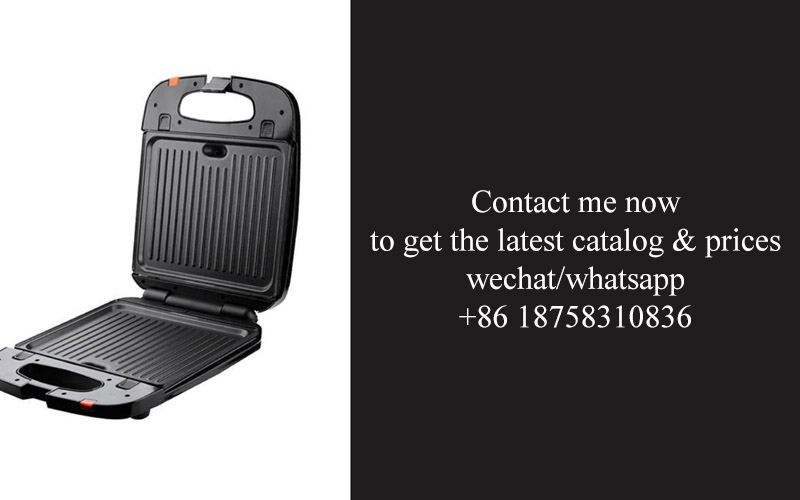

In terms of design, commercial sandwich presses have evolved to meet the needs of different kitchen environments. From countertop models that save space to heavy-duty units that can withstand the rigors of a high-traffic kitchen, there’s a commercial sandwich press to fit every setup. Some models even feature a sleek, modern aesthetic that can complement the design of contemporary dining spaces.

The rise of the commercial sandwich press is also a testament to the growing importance of food safety and hygiene in the foodservice industry. With the NSF (National Sanitation Foundation) approval, these presses are guaranteed to meet the highest standards of cleanliness and safety. This certification is a significant factor for many operators, as it reassures customers that their food is being prepared in a safe and hygienic environment.

From a business perspective, the adoption of commercial sandwich presses can lead to increased profitability. By reducing the time it takes to prepare sandwiches, these presses can help restaurants and cafes serve more customers in less time. This efficiency can translate into higher sales and improved customer satisfaction, which are crucial for long-term success in the competitive foodservice market.

Moreover, the convenience of a commercial sandwich press extends beyond the kitchen. These machines are easy to clean and maintain, which means less downtime and fewer headaches for kitchen staff. The durability of these presses also means they can withstand the test of time, providing a reliable investment for any establishment.

As the demand for fast and delicious food continues to grow, the commercial sandwich press is poised to become an even more integral part of the kitchen. With its ability to produce high-quality sandwiches quickly and efficiently, these presses are not just a tool but a strategic asset for any foodservice operator looking to stay ahead of the curve.

In conclusion, the rise of the commercial sandwich press is a clear sign of the changing landscape in the foodservice industry. As customers seek out quick, satisfying meals, these presses are stepping up to the plate, offering a solution that is both practical and innovative. Whether it’s a bustling café or a busy fast-food joint, the commercial sandwich press is proving to be a valuable ally in the quest to deliver the perfect sandwich, every time.

In the bustling world of commercial kitchens, the term “NSF approved” has become a beacon of trust and quality. This stamp of approval is not just a label; it’s a testament to the rigorous standards that products must meet to earn it. When it comes to commercial sandwich presses, understanding what the NSF approval means is crucial for both operators and consumers.

The NSF (National Sanitation Foundation) is an independent organization that sets the bar high for public health and safety. Their approval process involves thorough evaluation and testing of products to ensure they meet stringent criteria. For a commercial sandwich press to be NSF approved, it must pass a series of tests that cover everything from material safety to structural integrity.

Material safety is paramount in commercial kitchens, where cleanliness and hygiene are non-negotiable. An NSF approved sandwich press is constructed from materials that are free from harmful chemicals, ensuring that no contaminants can leach into the food being prepared. This is particularly important for a sandwich press, which comes into direct contact with ingredients like bread, meat, and condiments.

Structural integrity is another key factor. The NSF tests the sandwich press for durability and stability, ensuring that it can withstand the demands of a busy kitchen environment. This includes evaluating the heating elements for even distribution of heat, as well as the overall build quality to prevent any potential for malfunctions or leaks that could compromise food safety.

Beyond the physical attributes, the NSF also scrutinizes the sandwich press for ease of cleaning. Commercial kitchens are breeding grounds for bacteria, and a machine that is difficult to sanitize can become a hazard. An NSF approved sandwich press is designed with hygienic features that make it easy to clean, reducing the risk of cross-contamination and foodborne illnesses.

For operators, the NSF approval is a sign of reliability. It means that the sandwich press is built to last, saving money on repairs and replacements in the long run. It also signifies that the product has been vetted for its performance, ensuring that it will consistently deliver high-quality results day after day.

From a consumer’s perspective, the NSF approval is a guarantee of safety. When you see this certification on a commercial sandwich press, you can be confident that the food being prepared is being done so in a manner that adheres to the highest standards of cleanliness and safety. This can be particularly reassuring in the case of restaurants that cater to sensitive demographics, such as children, the elderly, or those with compromised immune systems.

The NSF also considers the user’s experience when granting approval. A sandwich press that is user-friendly not only makes the job of the kitchen staff easier but also reduces the likelihood of accidents. Features like easy-to-read temperature controls, intuitive interfaces, and ergonomic designs are all part of what makes a sandwich press NSF approved.

Moreover, the NSF approval process includes a review of the manufacturer’s quality control procedures. This ensures that not only does the sandwich press meet the current standards but that it will continue to do so throughout its lifespan. The manufacturer must demonstrate a commitment to maintaining these high standards, which is a significant factor in earning the NSF’s seal of approval.

In the competitive landscape of commercial kitchen equipment, the NSF approval is a differentiator. It sets a sandwich press apart from its competitors, signaling to potential buyers that it is a reliable and safe choice. This can be a deciding factor for businesses looking to invest in equipment that will stand the test of time and meet the evolving demands of health and safety regulations.

In conclusion, the NSF approval is more than just a piece of paper; it’s a comprehensive assessment of a commercial sandwich press’s ability to meet the most rigorous standards of quality and safety. For operators and consumers alike, it represents peace of mind, ensuring that every sandwich pressed is done so with the highest level of care and compliance.

In recent years, the world of commercial sandwich presses has seen a surge of innovation, pushing the boundaries of what these kitchen workhorses can do. As chefs and foodservice operators seek to enhance their offerings and streamline their operations, here are some of the key features that define the cutting-edge of sandwich press technology:

Precision Temperature Control: Modern sandwich presses often come with advanced temperature control systems. These systems ensure that the heat is evenly distributed across the entire surface of the press, resulting in a perfectly toasted sandwich every time. Look for models with precise temperature settings that can accommodate different types of bread and fillings.

Variable Pressure Adjustment: The art of making a great sandwich isn’t just about heat; it’s also about pressure. Newer models allow for variable pressure adjustments, which means you can customize the level of compression to suit various bread textures and thicknesses. This feature is particularly beneficial for achieving that perfect golden-brown crust while keeping the filling moist.

Non-Stick Coating: To maintain hygiene and prevent food from sticking to the press, many high-end models now feature a non-stick coating. This not only makes cleaning easier but also ensures that the sandwich maintains its shape and texture without the risk of crumbling.

Integrated Grilling Function: While the classic flat press is still popular, some sandwich presses now come with an integrated grilling element. This allows for a more diverse menu, as you can cook not only sandwiches but also burgers, paninis, and even pizzas. The ability to grill directly on the press can save time and space in the kitchen.

Programmable Settings: For those who want to automate their sandwich-making process, programmable settings are a game-changer. Users can set specific parameters for temperature, pressure, and cooking time, ensuring consistency across all batches. This is especially useful for high-volume operations where speed and uniformity are key.

Energy Efficiency: With the growing focus on sustainability, energy-efficient sandwich presses have become more common. Look for models that have features like automatic shut-off after a set period of inactivity or are designed to minimize energy consumption without compromising performance.

Compact and Durable Design: Commercial kitchens are always looking for ways to maximize space. Modern sandwich presses are designed to be compact yet robust, with durable construction that can withstand the rigors of a busy kitchen environment. A sturdy build not only ensures longevity but also reduces maintenance costs.

Customizable Interface: For ease of use, many sandwich presses now feature a user-friendly interface. This could be a digital display with simple controls or a more sophisticated touch screen that allows for quick adjustments. A well-designed interface can reduce training time for staff and improve efficiency.

Modular Components: Some models offer modular components, which means that parts can be easily replaced or upgraded. This flexibility is particularly useful as kitchen equipment evolves and operators look to future-proof their investments.

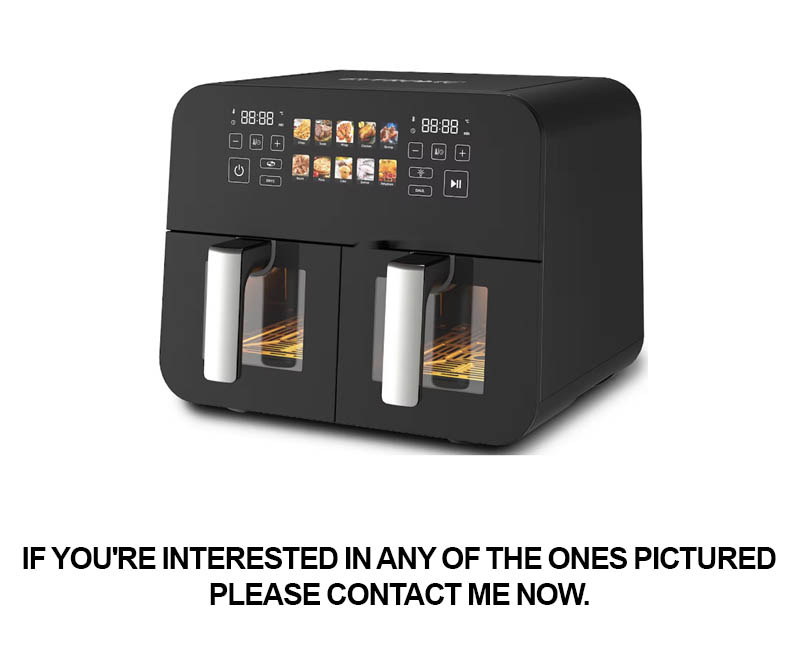

Smart Connectivity: While not yet mainstream, some sandwich presses are beginning to incorporate smart technology. This could include Wi-Fi connectivity for remote monitoring or integration with kitchen management systems to track usage and maintenance schedules.

By keeping an eye out for these innovative features, foodservice professionals can select the perfect sandwich press that not only meets their current needs but also has the potential to adapt to the evolving demands of the industry.

In the quest for the perfect sandwich, the right equipment is key. An NSF approved commercial sandwich press isn’t just a tool; it’s an investment in quality and consistency. Here are some tips to ensure you’re getting the most out of your sandwich-making experience with this versatile appliance:

The evenness of heat distribution is crucial for a well-cooked sandwich. Ensure your press has a uniform heating element that covers the entire surface. This guarantees that every bite is toasted to perfection without any cold spots or overcooked edges.

Maintaining the right temperature is vital. An NSF approved commercial sandwich press often comes with precise temperature controls. Learn to adjust these controls to your preferred level of crispiness. Too low, and your bread might not achieve the perfect golden-brown color; too high, and you risk burning the exterior while the inside remains undercooked.

The type of bread you use can significantly impact the sandwich’s final outcome. Thicker slices might require more heat to achieve a good toast, while thinner slices can burn easily. Experiment with different bread types and thicknesses to find the perfect match for your press.

Consistency is king in the sandwich world. An NSF approved commercial sandwich press can help you achieve this by allowing you to press down evenly. This not only ensures that the fillings are compacted but also that the bread is uniformly toasted. Keep the pressure steady throughout the process for consistent results.

Bread browning is a science. The temperature and time in the press contribute to the color of the bread. Keep an eye on the browning level, as it can give you a clue about the sandwich’s internal temperature. For a perfectly browned exterior, you might need to tweak the timing and temperature settings.

The press’s surface can make or break the sandwich’s texture. Non-stick coatings are a must for easy release and to prevent the bread from sticking. Make sure the surface is clean and well-lubricated to avoid any unwanted textures or flavors in your final product.

The speed at which you load and unload the sandwich can affect the quality. Quick and smooth movements help maintain the temperature and prevent the sandwich from cooling down too quickly. Practice your technique to minimize the time between pressing and serving.

Don’t underestimate the importance of clean surfaces. Regularly clean the press to remove any food particles or residue that could affect the taste or the performance of the appliance. A well-maintained press will last longer and ensure the best quality sandwiches.

Experiment with different fillings to see how they interact with the heat and pressure of the press. Some ingredients might require a slightly different cooking time or temperature to prevent them from becoming too dry or burning.

The size of the sandwich press can also influence your options. Larger presses can accommodate more substantial sandwiches, while smaller ones are great for single servings or delicate bread. Choose a size that fits your menu and customer preferences.

Remember, the quality of the ingredients is just as important as the equipment. Use fresh, high-quality ingredients to make the most of your sandwich press. The better the ingredients, the better the sandwich.

Lastly, don’t be afraid to experiment with different settings and techniques. The beauty of an NSF approved commercial sandwich press is its versatility. It can be used for a variety of sandwiches, from classic burgers to gourmet creations. The more you play with it, the more you’ll learn about what works best for your specific needs and tastes.

In the ever-evolving culinary landscape, the demand for convenience and quality in fast-food offerings has surged. This surge has paved the way for the sandwich press, a versatile tool that has become a staple in commercial kitchens. But why is now the perfect time to invest in a high-quality sandwich press? Let’s delve into the market trends that make this investment a wise choice.

The rise of the fast-casual dining segment has been a significant driver in the market. Consumers are seeking a balance between speed and quality, and the sandwich press offers a solution that can deliver both. With its ability to produce consistent, appealing sandwiches quickly, it’s no wonder that these presses are becoming a must-have in quick-service restaurants (QSRs) and cafes.

The health-conscious consumer trend is another factor propelling the demand for high-quality sandwich presses. As people become more aware of their dietary choices, they’re gravitating towards healthier meal options. A sandwich press can help chefs craft sandwiches that are not only delicious but also incorporate fresh ingredients and healthier cooking methods, such as grilling or toasting, rather than frying.

Technological advancements have also played a crucial role. Modern sandwich presses are equipped with features that were once only found in professional kitchens. From adjustable temperature controls to non-stick surfaces, these innovations ensure that every sandwich is cooked to perfection, every time. The integration of these technologies into the sandwich press market has made it a more sophisticated and reliable tool for chefs.

The convenience factor cannot be overstated. In a world where time is a luxury few can afford, the ability to quickly prepare a high-quality sandwich is invaluable. The sandwich press allows for efficient use of kitchen space, reduces labor costs, and streamlines the cooking process. This efficiency is particularly appealing to businesses looking to maximize their output without compromising on quality.

The global trend towards international cuisine has also opened new doors for the sandwich press. As cultures blend and food enthusiasts seek out diverse flavors, the sandwich press can be used to create a wide range of sandwiches, from classic American burgers to gourmet European-style paninis. This versatility means that restaurants can cater to a broader customer base, increasing their appeal and potential for growth.

Moreover, the sustainability movement has influenced the market for sandwich presses. As more businesses look to reduce their environmental footprint, energy-efficient models have gained popularity. These eco-friendly presses not only save on energy costs but also align with the values of a socially responsible brand.

The rise of food trucks and pop-up restaurants has created a new market segment that is particularly receptive to high-quality sandwich presses. These mobile kitchens require compact, durable, and easy-to-use equipment that can withstand the rigors of the road and the demands of a transient customer base. The sandwich press fits this bill perfectly, offering a solution that is both practical and adaptable.

Lastly, the impact of social media and influencer marketing cannot be ignored. The visual appeal of a perfectly toasted sandwich has the power to go viral, driving traffic to restaurants and increasing the demand for high-quality sandwich presses. The ability to create visually stunning sandwiches that capture the attention of social media users is a significant advantage for any establishment looking to stand out in a crowded market.

In conclusion, the market trends indicating that now is the best time to invest in a high-quality sandwich press are clear. The growing demand for convenience, health, and variety, coupled with technological advancements and the rise of eco-conscious consumers, all point to a favorable environment for this investment. Whether you’re a QSR, a café, a food truck, or a pop-up, a high-quality sandwich press can be a game-changer for your business, helping you to meet the evolving needs of your customers and stay ahead of the competition.

In the bustling world of fast-casual dining, the demand for quick, high-quality meals has never been higher. Among the innovations reshaping the industry, NSF-approved sandwich presses have become a staple. Let’s delve into a few case studies that showcase the success of these commercial appliances.

The first establishment to adopt the NSF-approved sandwich press was a trendy café in the heart of the city. The café, known for its fresh ingredients and artisanal flair, found that the press was the perfect match for their menu. The even heat distribution and precise pressure allowed them to craft perfectly toasted sandwiches with a golden crust, every time. Customers raved about the consistency and quality, and the café’s reputation for exceptional sandwiches soared.

Another case study involves a bustling sports bar that added the sandwich press to its kitchen lineup. The venue, which often saw a rush of patrons during game-time, needed a reliable way to serve up sandwiches quickly without compromising on taste. The NSF-approved press was a game-changer. It could handle the high volume, ensuring that every order was delivered hot and crisp. The press also allowed the chefs to experiment with different breads and fillings, keeping the menu fresh and exciting for regulars and newcomers alike.

A third instance comes from a university dining hall, where the sandwich press has become a student favorite. The hall, with its diverse and ever-changing crowd, needed a versatile solution that could cater to various dietary preferences. The NSF-approved press was chosen for its ability to toast a wide range of breads, from traditional loaves to gluten-free options. The consistency in the toasting process meant that every student received a sandwich that looked and tasted as good as it did in the commercial kitchen.

One of the standout features of the NSF-approved sandwich press is its ability to customize. A local deli replaced their outdated sandwich press with the newer model, and the results were immediate. The press’s adjustable heat settings and pressure control allowed the staff to tailor the toasting to each customer’s preference, whether they liked their sandwiches extra crispy or slightly toasted. This level of customization not only improved customer satisfaction but also helped the deli stand out in a competitive market.

In a similar vein, a health-conscious café that specializes in vegan and vegetarian options found that the sandwich press was the perfect tool for their needs. The café could now offer a variety of sandwiches that were both delicious and visually appealing, with each slice of bread evenly toasted. The press’s ability to maintain a consistent level of heat throughout the cooking process was crucial for achieving the perfect texture on each ingredient.

A popular fast-food chain also made the switch to the NSF-approved sandwich press, aiming to elevate their sandwich offerings. The press’s efficient operation and quick heating time meant that the chain could serve more customers in less time without sacrificing quality. The sandwiches that once took longer to prepare were now ready in a fraction of the time, allowing the staff to focus on other aspects of service.

In addition to improving the quality and speed of service, the NSF-approved sandwich press has also had a positive impact on the bottom line for many businesses. A small, local café reported a significant increase in sandwich sales after investing in the press. The consistency and the ability to produce high-quality sandwiches at a rapid pace attracted more customers, leading to increased revenue.

One of the most compelling reasons for the success of the NSF-approved sandwich press is its versatility. A gourmet burger joint that once relied on a less advanced model for their brioche buns found that the new press could also toast these delicate breads to perfection. The ability to toast various types of breads, from artisanal to traditional, has opened up new possibilities for menu creation and customer satisfaction.

Lastly, the durability of the NSF-approved sandwich press has been a standout feature for many businesses. A high school cafeteria, for example, has been using the same press for years without any issues. The robust construction ensures that the press can withstand the rigors of a busy kitchen, making it a reliable long-term investment.

In summary, the case studies of successful implementations of NSF-approved sandwich presses highlight their ability to improve quality, increase efficiency, and enhance customer satisfaction. From trendy cafes to busy sports bars and high-volume dining halls, these presses have proven to be a valuable asset in the quest for the perfect sandwich every time.

In recent years, the world of quick-service restaurants (QSRs) has witnessed a remarkable transformation, and technology has played a pivotal role in reshaping the way we think about sandwich making. From the rise of digital kiosks to the integration of precision cooking techniques, here’s a glimpse into how technology is revolutionizing the art of sandwich crafting.

Automated Cooking Systems are Redefining EfficiencyOnce a task solely handled by skilled chefs, sandwich preparation is now often managed by sophisticated automated cooking systems. These systems not only ensure consistency in sandwich quality but also drastically reduce the time it takes to serve customers. With precise temperature controls and timed processes, these systems are capable of delivering a perfect sandwich every time, regardless of the volume of orders.

Customization is King in the Tech-Driven QSRPersonalization has become a cornerstone of the modern QSR experience. Thanks to advancements in technology, customers can now choose from a wide array of ingredients and toppings, and the sandwich press takes care of the rest. From gluten-free bread options to a myriad of protein selections, the technology behind these presses allows for a nearly limitless variety of sandwich combinations.

Sustainability Meets EfficiencyThe increasing focus on sustainability has also influenced the design of modern sandwich presses. Energy-efficient models that reduce power consumption and are constructed with environmentally friendly materials are becoming more common. These innovations not only save costs in the long run but also align with the values of eco-conscious consumers, making sustainable practices part of the QSR’s brand identity.

Health and Safety Through TechnologyWith health concerns at the forefront, QSRs are incorporating technology to maintain the highest standards of hygiene. NSF approved sandwich presses are equipped with features that minimize cross-contamination, such as non-stick surfaces and easy-to-clean components. These innovations ensure that the food being served is safe, which is critical for maintaining customer trust and regulatory compliance.

The Role of Data AnalyticsModern sandwich presses are often equipped with sensors that track performance and collect data. This information can be invaluable for QSRs looking to optimize their operations. From identifying popular sandwich variations to predicting inventory needs, data analytics can help businesses make informed decisions that lead to improved efficiency and customer satisfaction.

Interactive Customer ExperiencesTechnology isn’t just about the cooking process; it’s also about enhancing the overall customer experience. QSRs are integrating touch-screen kiosks and mobile apps that allow customers to customize their sandwiches before they are even cooked. This interactive approach not only speeds up service but also creates a more engaging experience for the customer.

The Rise of Mobile Sandwich MakingMobile technology is another area where we’re seeing significant innovation. QSRs are now able to offer a “to-go” experience that is as seamless as it is convenient. With portable sandwich presses and mobile apps that guide customers through the ordering process, the future of sandwich making is becoming increasingly accessible.

The Integration of Social MediaSocial media has become a powerful tool for QSRs to showcase their sandwiches and engage with customers. High-quality images and videos of the sandwiches prepared by these advanced presses can be shared across various platforms, attracting new customers and encouraging repeat visits.

As we look to the future, it’s clear that technology is not just a buzzword in the QSR industry; it’s a driving force that is changing the way sandwiches are made and consumed. The combination of efficiency, customization, sustainability, and safety, all made possible by modern sandwich press technology, is setting the stage for a new era of quick-service dining.

In a world where speed and convenience reign supreme, the commercial sandwich press has emerged as a cornerstone of efficiency in quick service restaurants (QSRs). These versatile appliances have not only transformed the way sandwiches are prepared but have also set new standards for quality and consistency. Embracing the NSF approved commercial sandwich press can be a game-changer for any business aiming to thrive in today’s competitive foodservice landscape.

The precision and reliability of an NSF approved model ensure that every sandwich is crafted to perfection, with a golden-brown crust that locks in flavors and a satisfying crunch. But the benefits don’t stop there. Let’s delve into the subtle nuances that make these presses a worthwhile investment.

The consistent, even pressure applied by an NSF approved sandwich press guarantees that each piece of bread is evenly toasted, eliminating the possibility of cold spots or overdone areas. This attention to detail is crucial in maintaining the integrity of the sandwich’s flavor profile, especially when working with fresh, high-quality ingredients. The result is a sandwich that is both visually appealing and deliciously satisfying.

Moreover, the durability of these presses is unparalleled. Constructed with heavy-duty materials and designed to withstand the rigors of a busy kitchen environment, an NSF approved sandwich press is built to last. This longevity means fewer replacements and lower maintenance costs over time, making it a cost-effective choice for any QSR looking to streamline operations.

Another key feature is the adjustable temperature control. This allows chefs to tailor the heat to the specific requirements of their menu, ensuring that every sandwich is cooked to the desired level of crispiness. Whether you’re crafting a classic grilled cheese or a gourmet panini, the precision of an NSF approved sandwich press ensures consistency across all items.

Safety is paramount in the foodservice industry, and the NSF certification stands as a testament to the rigorous standards that these presses meet. From electrical safety to material integrity, the certification process ensures that each press is up to code and poses no risk to customers or staff. This peace of mind is invaluable for restaurant owners who want to create a safe dining experience.

Innovation in the world of sandwich presses doesn’t stop at the basic functionalities. Many modern models come with features like non-stick surfaces, which reduce the need for butter or oil and help maintain the integrity of the bread. Others include programmable settings, allowing for the quick adjustment of cooking times and temperatures with the touch of a button. These features not only simplify the cooking process but also open up possibilities for creative menu items.

Case in point, a local café upgraded to an NSF approved sandwich press and saw a significant boost in customer satisfaction. The consistent quality of the sandwiches, coupled with the ability to offer new, gourmet options, helped the café stand out in a crowded market. This success story is a testament to the impact that a high-quality sandwich press can have on a business’s bottom line.

As for the future, technology continues to evolve the way we think about sandwich making. Emerging trends suggest that we’ll see even more sophisticated features in sandwich presses, such as built-in timers to alert chefs when the perfect sandwich is ready and smart interfaces that can integrate with kitchen management systems. These advancements will not only enhance the efficiency of QSRs but also provide new opportunities for customization and innovation.

In conclusion, investing in an NSF approved commercial sandwich press is a strategic move for any business aiming to excel in the quick service restaurant industry. With their precision, durability, safety features, and innovative designs, these presses are more than just appliances; they are tools that can elevate the quality of your sandwiches and, in turn, the reputation of your establishment. Whether you’re a seasoned restaurateur or just starting out, the benefits of embracing this technology are clear and undeniable.