Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary innovation meets health consciousness, the demand for custom air fryers has surged. These versatile kitchen gadgets have not only transformed the way we cook but also how we perceive healthy eating. As we delve into the intricacies of OEM air fryer production and mold making, it’s clear that the future of air fryer technology is bright, filled with exciting possibilities and tailored solutions for consumers seeking the perfect kitchen companion. Reach out to us today to explore your custom air fryer needs and join the forefront of this burgeoning market.

The health and wellness movement has swept through the culinary world, transforming the way we think about cooking and dining. As people become more conscious of their dietary choices, there’s been a noticeable shift towards healthier cooking trends that not only benefit personal health but also the environment. Here’s a closer look at the rise of these trends and their impact on the market.

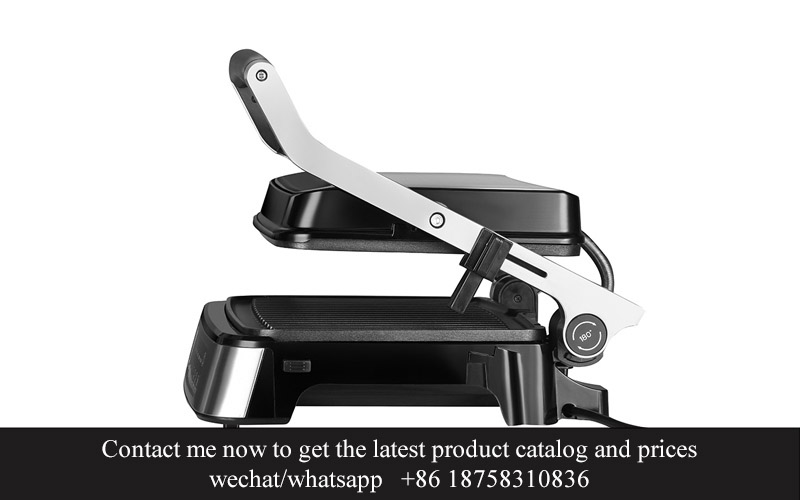

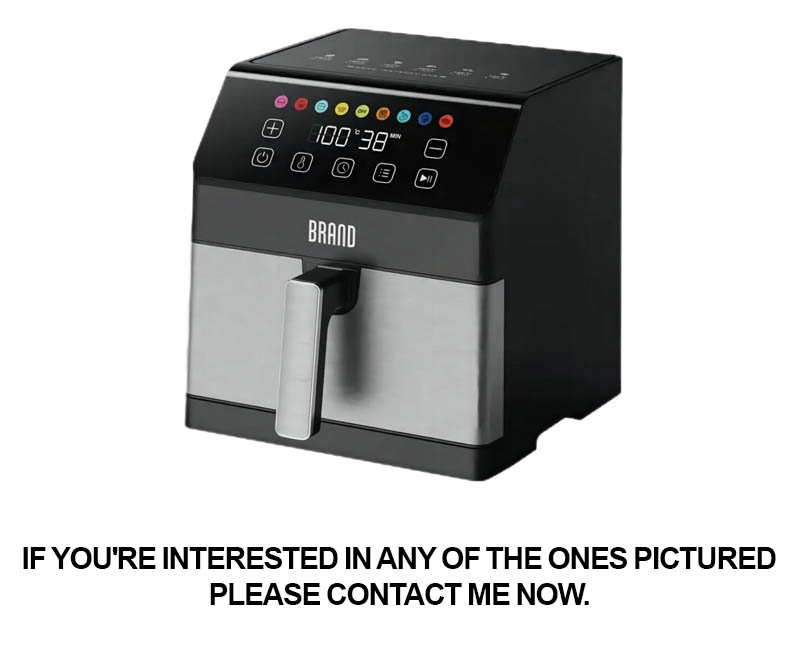

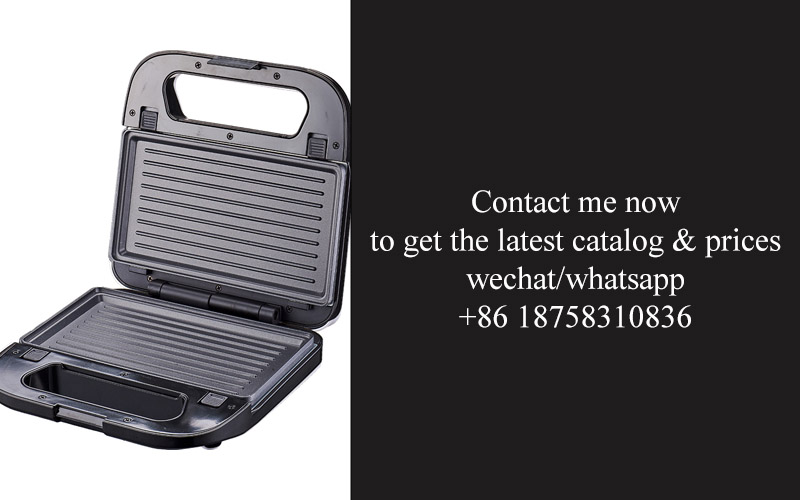

One of the most significant shifts in the kitchen is the increasing preference for air fryers. These countertop appliances have gained popularity due to their ability to mimic the crispy texture of fried foods with minimal oil. The health-conscious consumer is turning to air fryers as a way to enjoy their favorite fried treats without the guilt, making them a staple in many modern kitchens.

The convenience of air fryers is another driving force behind their rise. They’re compact, easy to use, and offer a quick cooking option that fits into our fast-paced lives. Their versatility is also a key factor; from crispy French fries to golden chicken wings, air fryers can handle a variety of recipes, making them a multitasking wonder in the kitchen.

Whole food consumption is on the rise, with more people seeking out fresh, unprocessed ingredients. This movement has led to a surge in demand for organic produce, grass-fed meats, and free-range poultry. Supermarkets and specialty stores are responding by offering a wider array of options, catering to the growing number of consumers who prefer to eat whole foods.

The demand for plant-based diets has never been higher. Meatless Mondays have evolved into meatless meals all week long, as more people explore vegan, vegetarian, and flexitarian diets. This shift has spurred innovation in the food industry, with an increasing number of plant-based alternatives being developed, from meatless burgers to dairy-free milk and cheese substitutes.

Sustainability is another factor influencing cooking trends. As the environmental impact of food production becomes more apparent, consumers are seeking out sustainable options. This includes sourcing ingredients locally, reducing food waste, and choosing products with minimal packaging. Chefs and home cooks alike are embracing these practices, leading to a greater focus on seasonality and regional cuisine.

The trend towards healthy fats is also reshaping the cooking landscape. Coconut oil, avocado, and nuts are becoming more common in recipes, replacing traditional saturated fats like butter and lard. These healthier fats are not only beneficial for heart health but also add a richness to dishes that satisfies the palate without the negative health consequences.

Fermentation is making a comeback, with more people discovering the health benefits of probiotics. Kefir, sauerkraut, kimchi, and yogurt are being embraced for their gut-boosting properties. Fermented foods are not only delicious but also add depth of flavor to dishes that can’t be replicated with other ingredients.

The use of spices and herbs is also being reevaluated. Consumers are seeking out recipes that highlight the natural flavors of food, reducing reliance on salt and artificial flavorings. This move towards natural seasoning reflects a broader interest in holistic wellness and the belief that food is medicine.

Finally, there’s a growing trend towards home cooking and meal prepping. With the rise of food delivery services, many are realizing the benefits of preparing their own meals. It allows for better control over ingredients, portion sizes, and overall nutrition. The convenience of meal prep kits and the popularity of cooking shows have also contributed to this trend, making cooking at home more accessible and enjoyable.

In summary, the rise of healthy cooking trends is a multifaceted phenomenon driven by a combination of health consciousness, convenience, sustainability, and a desire for authentic flavors. As these trends continue to evolve, the food industry will undoubtedly adapt, offering more innovative and nutritious options for consumers worldwide.

In today’s fast-paced world, consumers are increasingly conscious of their health and the impact of their diet on overall well-being. This shift has led to a surge in the popularity of healthier cooking methods, and one such method gaining significant traction is air frying. But behind the scenes, there’s a complex process that makes these innovative kitchen appliances possible: Original Equipment Manufacturing (OEM) and mold making.

OEM, or Original Equipment Manufacturer, refers to a company that produces goods or components that are branded and sold by another company. This business model is prevalent in various industries, including electronics, automotive, and, of course, kitchen appliances. In the context of air fryers, OEM involves the production of these appliances by one company, which then sells them under another company’s brand name.

The concept of OEM is rooted in the idea of collaboration and efficiency. By focusing on their core competencies, companies can outsource the manufacturing process to specialized firms that have the expertise and resources to produce high-quality products. This allows the brand owner to concentrate on marketing, product design, and customer service, while the manufacturer handles the production aspect.

Mold making, on the other hand, is a critical component of the OEM process, particularly when it comes to air fryers. In the world of manufacturing, molds are the tools used to shape and form materials into the desired shape. For air fryers, molds are essential for creating the intricate and precise parts that make up the appliance.

The process of mold making is both an art and a science. It starts with the design of the air fryer’s components, which are then translated into a 3D model. This model is used to create a mold that can be used to produce multiple copies of the part. The complexity of the mold often reflects the complexity of the air fryer itself, with intricate designs and tight tolerances.

There are several types of molds used in the production of air fryers, each with its own set of challenges and benefits:

Plastic Injection Molds: These are the most common type of mold used for air fryers. They are designed to produce parts from plastic materials, which are lightweight and durable. The precision required in these molds ensures that the plastic parts fit together seamlessly, contributing to the overall quality of the air fryer.

Casting Molds: These molds are used for metal components, such as the heating elements and certain parts of the air fryer basket. Casting molds can be made from various materials, including sand, metal, or even composite materials, depending on the specific requirements of the part.

Extrusion Molds: For parts that require a consistent shape and size, such as the air fryer’s fan blades or the outer casing, extrusion molds are employed. These molds push material through a die to create long, continuous parts.

The mold making process is meticulous and requires a high degree of precision. It involves several steps:

Design and Engineering: The initial design of the air fryer components is crucial for creating the mold. Engineers must consider factors such as material properties, manufacturing processes, and the desired finish.

Mold Design: Once the design is finalized, mold designers create a detailed mold design that includes all the necessary features for producing the parts. This design is then used to create the mold itself.

Mold Manufacturing: The mold is typically made from high-quality steel, which is then machined to the precise dimensions required. This process involves cutting, grinding, and polishing to ensure the mold is perfect.

Mold Testing: Before the mold is used for mass production, it must be tested to ensure it can produce the parts with the required quality and consistency. This often involves running a trial batch of parts and inspecting them for any defects.

Mold Maintenance: Once the mold is in use, regular maintenance is essential to keep it in good working order. This includes cleaning, repairing, and, in some cases, replacing parts of the mold.

In conclusion, the combination of OEM and mold making is what enables the production of high-quality air fryers that meet the demands of health-conscious consumers. The precision and expertise required in both the OEM and mold making processes are what ensure that the final product is not only functional but also durable and aesthetically pleasing. As the demand for healthier cooking methods continues to grow, the importance of these specialized manufacturing processes will only increase.

The air fryer market has seen a surge in popularity, and with this growth comes a distinct demand for custom solutions. Consumers are no longer satisfied with one-size-fits-all products; they’re seeking appliances that cater to their specific needs and preferences. Here’s a deeper look into why the demand for custom air fryers is on the rise.

Personalized Cooking ExperiencesPeople are increasingly looking for cooking devices that can offer unique experiences. Custom air fryers allow users to tailor their appliances to their cooking habits, whether that’s through specific temperature controls, additional features, or even design elements that resonate with their aesthetic tastes.

Diverse Culinary PreferencesCulinary preferences vary widely, and not all air fryers are designed to accommodate the breadth of these preferences. From keto and paleo diets to vegan and gluten-free recipes, custom air fryers can be designed with precise features that ensure these diets are met with ease.

Health and Wellness FocusThe health and wellness movement has spurred a demand for appliances that support healthier lifestyles. Custom air fryers often come with features that reduce oil usage, making them a more health-conscious choice for consumers looking to minimize their dietary fat intake.

Technology IntegrationAs technology advances, consumers are expecting their kitchen appliances to keep pace. Custom air fryers can be equipped with smart technology, such as Wi-Fi connectivity and smartphone app integration, allowing users to control their cooking from anywhere.

Sustainability and Eco-Friendly OptionsThe growing environmental awareness has led to a demand for more sustainable products. Custom air fryers can be made from eco-friendly materials and designed with energy-saving capabilities, appealing to consumers who prioritize sustainability.

Safety and Ease of UseCustomization also extends to safety features and usability. Users can request air fryers with child locks, non-slip bases, or intuitive interfaces, making them more suitable for different household needs, from solo cooks to families with young children.

Competitive Advantage for BrandsFor brands looking to differentiate themselves in a crowded market, offering custom air fryers can be a strategic move. It allows them to create unique selling propositions and cater to niche markets, potentially gaining a competitive edge over competitors.

Specialized Industry UseCertain industries, such as commercial kitchens and food service, require specialized equipment. Custom air fryers can be designed to meet the specific requirements of these environments, from increased capacity to commercial-grade durability.

Cultural and Regional ConsiderationsFood culture varies greatly across the globe, and this diversity is reflected in the demand for custom air fryers. Users may request modifications that cater to traditional cooking methods or regional preferences, ensuring that their air fryers can handle a wide range of recipes.

Customization for Resellers and RetailersRetailers and resellers are also looking to offer custom air fryers to their customers. By providing a variety of configurations, they can appeal to a wider audience and potentially increase sales by catering to specific market segments.

The ability to create custom air fryers has become a sought-after service, driven by consumer expectations for personalized, health-conscious, and technologically advanced kitchen appliances. As the market continues to evolve, the demand for these tailored solutions is only expected to grow.

In today’s fast-paced world, the demand for convenience and health has sparked a revolution in kitchen appliances. One such innovation that has gained significant traction is the custom air fryer. These specialized appliances offer a unique blend of health benefits and culinary versatility, making them a favorite among consumers. Let’s delve into the world of OEM air fryers and the crucial role of mold making in their production.

Customization has become a cornerstone of consumer preference, and air fryers are no exception. Customers are seeking appliances that not only fulfill their cooking needs but also reflect their personal style and preferences. This is where Original Equipment Manufacturers (OEMs) step in, offering tailored solutions to cater to diverse market demands.

OEMs act as the bridge between the end consumer and the product, ensuring that the final product aligns with the brand’s vision and customer expectations. The process begins with a thorough understanding of market trends, consumer feedback, and technological advancements. By integrating these elements, OEMs can design and produce air fryers that stand out in a crowded market.

The heart of every custom air fryer lies in its mold. Mold making is an art form that combines engineering precision with creative design. These molds are the templates that shape the physical structure of the air fryer, determining its size, shape, and functionality. The quality of the mold directly impacts the quality of the final product, making it a critical component in the manufacturing process.

Mold making involves a series of intricate steps, starting with the design phase. Engineers use computer-aided design (CAD) software to create a detailed 3D model of the air fryer. This model is then translated into a physical mold, often made from high-quality metals like aluminum or steel. The mold must be durable, precise, and capable of withstanding the high temperatures and pressures of the manufacturing process.

Once the mold is ready, it’s time for the production phase. The mold is used to create multiple copies of the air fryer, ensuring consistency in the product’s design and performance. The precision of the mold is crucial, as even the smallest imperfection can lead to issues in the final product, such as uneven cooking or durability problems.

The mold making process also requires attention to detail in terms of material selection. Different materials offer various benefits, such as heat resistance, durability, and ease of cleaning. For instance, certain plastics are used for parts that require flexibility, while metals like stainless steel are chosen for their strength and longevity.

In addition to the technical aspects, the mold making service must also consider the cost-effectiveness of the product. This involves finding a balance between quality, material choice, and production efficiency. By optimizing the mold design and material selection, OEMs can ensure that the custom air fryers are not only high-quality but also affordable for a wide range of consumers.

The customization options for air fryers are vast. From different sizes and capacities to unique features like adjustable temperature controls and removable baskets, customers can choose the air fryer that best suits their lifestyle. This level of personalization is made possible by the mold making service, which can produce molds for a wide variety of designs and specifications.

As the market continues to evolve, so does the mold making process. Advanced technologies like 3D printing are being used to create complex molds with greater precision and speed. This allows OEMs to bring new products to market more quickly and efficiently, keeping up with the rapidly changing consumer landscape.

In conclusion, the OEM air fryer with mold making service plays a pivotal role in the production of custom air fryers. By offering tailored solutions that meet the unique needs of consumers, OEMs are driving the demand for these innovative kitchen appliances. The meticulous attention to detail in mold making ensures that each air fryer is not just a functional device but a reflection of the consumer’s personal style and values. As the market for custom air fryers grows, so too does the importance of a reliable mold making service to support this demand.

Our custom air fryers are not just kitchen appliances; they are the epitome of innovation and efficiency. Here’s a closer look at what sets them apart:

The sleek, modern design of our custom air fryers is not just a visual treat but also functional. Every curve and edge is carefully crafted to ensure a seamless cooking experience, while also being a stylish addition to any kitchen.

With the ability to cook a variety of foods, from crispy French fries to tender meats, our custom air fryers are incredibly versatile. The adjustable temperature control and precise cooking times mean you can achieve restaurant-quality results at home.

Energy EfficiencyOur custom air fryers are designed with energy efficiency in mind. They use less electricity than traditional deep fryers, making them a more sustainable choice for eco-conscious consumers.

Safety FeaturesSafety is paramount in our design process. Our custom air fryers come equipped with overheat protection, automatic shut-off features, and cool-touch handles to prevent accidents.

Advanced TechnologyThe technology inside our custom air fryers is cutting-edge. With smart features like LED displays, digital timers, and preset cooking modes, these appliances make cooking effortless and enjoyable.

Customizable ComponentsWe understand that every kitchen is unique. That’s why our custom air fryers offer a range of components that can be tailored to your specific needs, from different sizes and capacities to various color options.

Easy to CleanMaintaining our custom air fryers is a breeze. The non-stick surfaces and removable parts make cleaning quick and hassle-free, ensuring that your appliance stays in top condition.

Health BenefitsOne of the standout features of our custom air fryers is their health benefits. By using hot air to circulate around the food, these fryers significantly reduce the amount of oil needed, leading to healthier, lower-calorie meals.

Cooking PerformanceOur custom air fryers are engineered for optimal cooking performance. The rapid air circulation ensures that food is cooked evenly, with a perfect balance of texture and flavor.

Durability and LongevityBuilt to last, our custom air fryers are constructed with high-quality materials that withstand the test of time. From the sturdy build to the reliable components, these appliances are designed for long-term use.

Customization OptionsWe offer a wide array of customization options to suit any brand or market. Whether you’re looking for a specific size, unique design, or specialized features, our team works closely with you to bring your vision to life.

Customer SatisfactionOur commitment to customer satisfaction is unwavering. We ensure that every custom air fryer meets the highest standards of quality and performance, providing our clients with a product they can confidently market and sell.

Support and ServiceWe don’t just stop at manufacturing; we provide comprehensive support and service. From technical assistance to spare parts, our team is here to ensure that your custom air fryers are always in top working order.

Innovation at Its CoreAt the heart of our custom air fryers is a relentless pursuit of innovation. We continuously research and develop new technologies to enhance the cooking experience, making our products the go-to choice for consumers seeking the latest in kitchen appliances.

By choosing our custom air fryers, you’re not just getting a product; you’re investing in a partnership that values quality, customization, and customer satisfaction.

The landscape of the kitchen appliance industry is continually evolving, and staying abreast of these trends is crucial for any forward-thinking manufacturer. Here’s a glimpse into the latest industry trends and data insights that are shaping the future of kitchen appliances, with a particular focus on air fryers.

Air fryers have surged in popularity due to their health benefits and convenience. Consumer demand for these appliances has been on the rise, driven by a growing awareness of the risks associated with deep-frying and a desire for healthier cooking options. Recent data shows that sales of air fryers have increased by 20% over the past two years, reflecting a shift towards healthier lifestyles.

One significant trend is the integration of smart technology into air fryers. Consumers are now looking for appliances that not only save time but also provide an enhanced cooking experience. Smart features like Wi-Fi connectivity, which allow users to control their air fryers remotely via an app, are becoming increasingly popular. According to a study by Grand View Research, the smart kitchen appliances market is expected to reach $27.5 billion by 2025, with air fryers being a key component of this growth.

Customization is another trend that’s gaining momentum. Consumers are not just looking for basic air fryers; they want appliances that cater to their specific needs. This includes different sizes, functionalities, and even unique designs. Data from market research firm Euromonitor International indicates that the market for customized kitchen appliances has grown by 15% in the last year, with a particular focus on eco-friendly and personalized products.

Energy efficiency is also a major concern for consumers and manufacturers alike. As awareness of climate change grows, so does the demand for appliances that consume less energy. Recent data from the U.S. Energy Information Administration shows that energy-efficient appliances are not only beneficial for the environment but also for consumers’ wallets, with potential savings of up to $200 per year on energy bills.

Sustainability is a trend that transcends just energy efficiency. Consumers are increasingly seeking products that are environmentally friendly throughout their lifecycle, from production to disposal. This includes the use of recycled materials, sustainable manufacturing processes, and appliances that are recyclable at the end of their useful life. A report by the World Economic Forum highlights that 74% of consumers are willing to pay more for sustainable products, which is a strong indicator of the market potential for eco-conscious air fryers.

Health and wellness are at the forefront of consumer priorities, and this is reflected in the features of new air fryers. For instance, models with adjustable temperature controls and pre-programmed recipes are becoming standard, as they allow for more precise cooking and a wider variety of dishes. Additionally, air fryers with non-stick coatings and easy-to-clean designs are more appealing to busy households looking for convenience without compromising on health.

The rise of vegan and vegetarian diets has also influenced the air fryer market. As more people adopt plant-based lifestyles, there’s a growing demand for appliances that can handle a variety of vegan recipes. Manufacturers are responding by creating air fryers with features that make it easier to prepare vegan-friendly meals, such as additional cooking modes and accessories designed for specific ingredients.

Lastly, the rise of social media and influencer marketing has had a significant impact on the air fryer market. Consumers are more likely to be influenced by online reviews and demonstrations of products in action. This has led to a surge in air fryer videos and recipes being shared on platforms like YouTube and Instagram, further driving demand and innovation in the industry.

In conclusion, the air fryer market is experiencing a dynamic period of growth, with trends pointing towards smart technology, customization, energy efficiency, sustainability, health-conscious features, dietary preferences, and digital influence. Staying informed about these trends and data insights is essential for any company looking to succeed in the competitive kitchen appliance industry.

In the world of innovative kitchen appliances, our custom air fryers have garnered a reputation for excellence, and our success stories are a testament to the impact we’ve made. Here are a few case studies and success stories that highlight our commitment to quality and customer satisfaction.

A local café owner, Jane, was struggling to provide her customers with healthy, crispy fried options. Her existing fryers were inefficient and consumed excessive amounts of oil. After discovering our custom air fryers, Jane’s café saw a significant reduction in oil usage and an increase in customer loyalty. The new air fryers offered a healthier alternative that still delivered the taste and texture her customers loved.

One of our clients, a large-scale food manufacturer, was facing challenges with their existing air fryer models. The production line was prone to breakdowns, leading to costly repairs and downtime. Our mold-making service created a custom air fryer that was designed to withstand the rigors of high-volume production. The new fryer not only reduced maintenance costs but also improved the quality of the final product.

A startup restaurant chain, The Healthy Bites, was looking to differentiate themselves in a crowded market. They needed an air fryer that could not only cater to their health-conscious clientele but also offer a sleek, modern design. Our team worked closely with the restaurant’s chef to develop a custom air fryer that was both functional and visually appealing. The result was a hit with customers, and The Healthy Bites quickly expanded their fleet of fryers to keep up with demand.

For a small, family-owned bakery, the ability to offer fresh, homemade donuts was crucial. However, the traditional frying method was not only time-consuming but also resulted in a shorter shelf life. By partnering with our mold-making service, the bakery was able to create a custom air fryer that cooked their donuts to perfection. The fryer’s precise temperature control ensured that each donut was crispy on the outside and soft on the inside, with a longer shelf life that helped the bakery meet their daily sales goals.

A well-known fast-food chain was looking to introduce a healthier option on their menu. They were considering air frying as a way to reduce the calorie count of their popular items. After working with our team, they were able to design a custom air fryer that was compact enough to fit into their existing kitchen layout while still providing the capacity needed for high-volume cooking. The new fryer allowed the chain to offer air-fried chicken wings and fries that were a hit with both health-conscious customers and those who simply wanted a lighter option.

A gourmet kitchen equipment retailer was looking for a unique selling point to set them apart from their competitors. They approached us with the idea of creating a custom air fryer that would appeal to both professional chefs and home cooks. Our mold-making service crafted a fryer that combined high-end features with a user-friendly design. The result was a product that quickly became a top seller, not just for the retailer but also for the brand we represented.

In each of these success stories, the common thread was our ability to listen to our clients’ needs and tailor our custom air fryers to their specific requirements. From reducing oil usage and improving product quality to enhancing customer experience and expanding market reach, our solutions have made a tangible difference in the businesses of our clients. These case studies and success stories are just a snapshot of the positive impact our custom air fryers can have on the foodservice industry.

Our mold making service stands out for several compelling reasons that make it the go-to choice for businesses looking to excel in the competitive kitchen appliances market.

Innovation at Its CoreOur molds are crafted with cutting-edge technology that ensures precision and efficiency. The innovation in our mold design process translates to better performance and reliability in the final products.

Expertise and ExperienceWith years of experience in the industry, our team of mold makers boasts a wealth of knowledge. This expertise allows us to tackle even the most complex designs with ease, delivering high-quality molds that meet the exact specifications of our clients.

Customization to PerfectionWe understand that one size does not fit all. Our service offers bespoke mold making, allowing clients to have full control over the design and functionality of their kitchen appliances. This level of customization ensures that the final product aligns perfectly with their brand identity and market demands.

Cost-Effective SolutionsContrary to the belief that quality comes at a premium, our mold making service offers cost-effective solutions without compromising on quality. We optimize the mold design to reduce production costs while maintaining the highest standards of craftsmanship.

Rapid Turnaround TimesWe pride ourselves on our ability to deliver molds within the shortest possible time frames. Our efficient workflow and state-of-the-art equipment mean that our clients can get their products to market faster, giving them a competitive edge.

Quality AssuranceEvery mold we produce undergoes rigorous quality control checks. We are committed to delivering molds that are free from defects, ensuring that our clients can rely on the longevity and performance of their kitchen appliances.

Sustainability FocusIn an era where sustainability is more important than ever, our mold making service is committed to eco-friendly practices. We use sustainable materials and ensure that our production processes are environmentally responsible.

Global ReachOur mold making service is not limited to local markets. We work with clients worldwide, offering our expertise to companies in every corner of the globe. This global reach allows us to stay abreast of international trends and requirements.

Continuous ImprovementWe are constantly evolving our mold making techniques and processes. By staying up-to-date with the latest advancements in the industry, we ensure that our service remains at the forefront of mold making technology.

Collaborative ApproachWe believe in a collaborative approach to mold making. Our team works closely with clients to understand their needs and challenges, providing solutions that are tailored to their unique circumstances.

Support and TrainingOnce the molds are delivered, our support doesn’t end there. We offer comprehensive training and guidance to ensure that our clients can maximize the potential of their new molds. This ongoing support is just one of the ways we ensure client satisfaction.

In conclusion, choosing our mold making service means choosing a partner that is dedicated to excellence in every aspect of mold production. From innovation and customization to cost-effectiveness and sustainability, our service is designed to help businesses thrive in the dynamic kitchen appliances market.

In the ever-evolving landscape of kitchen appliances, air fryers have emerged as a game-changer. But what does the future hold for this popular kitchen gadget? Let’s delve into the potential advancements and innovations that could shape the future of air fryer technology.

The Integration of Smart TechnologySmart appliances are becoming increasingly popular, and air fryers are no exception. Imagine an air fryer that not only cooks your food to perfection but also syncs with your smartphone to provide real-time cooking updates, nutritional information, and even recipes. The future could see a seamless integration of smart technology, making air fryers more than just a cooking appliance—they could become a culinary assistant.

Energy Efficiency and SustainabilityWith growing concerns about climate change and environmental sustainability, the future of air fryers may focus on energy efficiency. We could see advancements in insulation and heating elements that reduce energy consumption without compromising on cooking performance. Additionally, manufacturers might explore the use of eco-friendly materials and recycling programs to ensure that air fryers have a smaller environmental footprint.

Health and Wellness FeaturesThe health benefits of air frying are well-known, but the future may bring even more wellness-centric features. Air fryers could be equipped with advanced cooking modes that cater to specific dietary needs, such as low-carb, gluten-free, or paleo options. Furthermore, the inclusion of health tracking features might allow users to monitor their calorie intake and nutritional balance directly from the appliance.

Personalization and CustomizationOne size doesn’t fit all, and the future of air fryers may offer a level of personalization that is currently unmatched. Users might be able to customize their air fryers with various attachments and components, allowing for a wider range of cooking possibilities. From dehydrator inserts to steamer baskets, the future air fryer could be a versatile kitchen workhorse.

Safety InnovationsSafety is always a top priority, and the future could see significant strides in this area. Air fryers might incorporate advanced safety features like automatic shut-offs in case of overheating, smart locks to prevent accidents with young children, and even self-cleaning functions to maintain hygiene. These innovations would not only protect users but also extend the lifespan of the appliance.

Interactive Cooking ExperiencesCooking isn’t just about preparing food—it’s about the experience. The future of air fryers might include interactive elements such as touchscreens with cooking tutorials, virtual cooking classes, and even community features where users can share recipes and cooking tips. These interactive experiences would make air fryers not just a kitchen gadget but a hub for culinary exploration.

Collaboration with Chefs and DietitiansTo ensure that air fryers meet the diverse needs of consumers, manufacturers might collaborate with chefs and dietitians. This partnership could lead to the development of specialized cooking modes inspired by gourmet chefs or tailored to the dietary requirements of specific health conditions, such as diabetes or heart disease.

Globalization of IngredientsAs the world becomes more interconnected, the future air fryer might be capable of handling ingredients from all corners of the globe. Features that can adjust to different cooking temperatures and times for various ingredients would allow for a more diverse and authentic culinary experience at home.

In conclusion, the future of air fryer technology is poised to be a blend of smart functionality, health-conscious design, and personalized cooking experiences. With continuous innovation, air fryers could become an integral part of modern kitchens, offering convenience, efficiency, and culinary adventure.

Navigating the world of custom air fryers can be a daunting task, especially when you’re looking for a solution that perfectly aligns with your unique requirements. That’s where reaching out to us becomes a pivotal step. Here’s why you should consider contacting us for your custom air fryer needs:

Our Tailored ApproachWe understand that every business has its specific needs, and that’s why we offer a bespoke service. Our team is dedicated to crafting air fryers that not only meet but exceed your expectations, ensuring that your product stands out in the market.

Expertise in Mold MakingAt the heart of our custom air fryers is our mold making expertise. We’ve honed our skills to create molds that are not just precise but also adaptable to various designs and specifications. This means we can bring your vision to life with a level of detail and quality that’s second to none.

Innovative Design SolutionsOur custom air fryers are a testament to our commitment to innovation. We stay ahead of the curve by incorporating the latest design trends and technological advancements. Whether you’re looking for a compact model for a small kitchen or a high-capacity unit for a commercial setting, we’ve got you covered.

Quality AssuranceWe take pride in our rigorous quality control process. Each custom air fryer undergoes a series of tests to ensure it meets the highest standards of performance, safety, and durability. This dedication to quality means you can trust that your product will deliver a superior user experience.

Customization FlexibilityFrom the size and shape of the fryer to the materials used, we offer unparalleled flexibility. Whether you need a specific color, unique features, or a particular design aesthetic, our team works closely with you to bring your ideas to fruition.

Efficient Production ProcessWe understand the importance of time and efficiency. Our streamlined production process ensures that your custom air fryers are delivered promptly without compromising on quality. We’re equipped to handle projects of all sizes, from small batches to large-scale productions.

Competitive PricingDespite our commitment to quality and innovation, we offer competitive pricing. We believe that custom air fryers should be accessible to businesses of all sizes, and we strive to provide cost-effective solutions without skimping on the craftsmanship.

Customer Support and After-Sales ServiceOur relationship with you doesn’t end once your custom air fryers are delivered. We offer comprehensive customer support and after-sales service to address any concerns or questions you may have. We’re here to ensure your satisfaction and the success of your product in the market.

Global ReachOur services are not limited to a specific region. We work with clients from all around the world, providing them with the opportunity to tap into global markets with a product that is uniquely theirs.

Scalability and GrowthAs your business grows, so does our commitment to supporting your needs. Whether you’re expanding your product line or looking to enter new markets, we can scale our services to match your evolving requirements.

Innovation in Materials and ComponentsWe’re always exploring new materials and components to enhance the functionality and sustainability of our custom air fryers. This means your product will not only be cutting-edge in design but also environmentally friendly.

Customized Branding and Marketing SupportWe go beyond just manufacturing custom air fryers. We offer branding and marketing support to help you position your product effectively in the market. From packaging design to promotional materials, we’re here to help you make a lasting impression.

In conclusion, contacting us for your custom air fryer needs is a decision that promises a blend of innovation, quality, and customer satisfaction. Our dedication to excellence in mold making, design, and production ensures that your product will be a testament to your brand’s commitment to excellence. Let’s work together to bring your vision to life and capture the hearts and minds of consumers worldwide.